hunter306

Well-Known Member

- Joined

- Oct 18, 2013

- Messages

- 396

- Reaction score

- 87

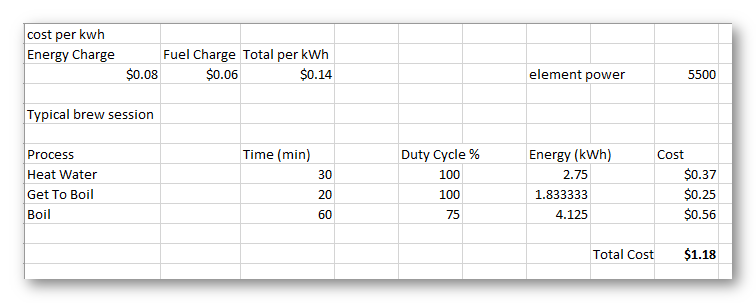

So, How much does it cost to run our electric breweries?

Recently, the power company installed these fancy new smart meters that let us do hour-by-hour tracking of our home energy use. Obviously, being a bit of a geek, I was curious what our rough energy use and cost was for a standard Brewday (usually 10gal out of the fermenter).

Here's what I came up with (These are fairly rough calculations for the sake of simplicity).

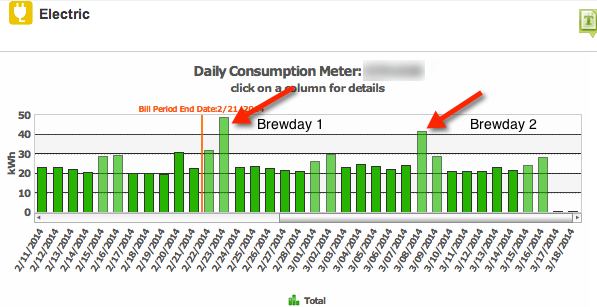

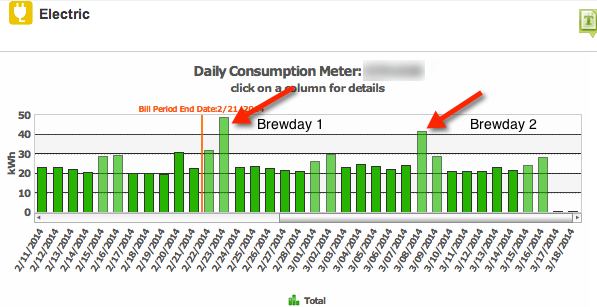

Baseline Energy Use vs. Brewdays:

From this, we learn a few things. First, on an average day*, we're using about 22kw/h of power for everyday stuff. TV, Fans, Lights, Microwave, Refrigerator etc. On a Brewday, the energy usage increases about 43kw/h of power total.

*NOTE: You'll have to excuse the spikes to around 30kw/h on this graphic before the first brewday, these were days where we were testing the Brewing system (we omitted these from the normal use baseline).

Knowing this, we can assume that our standard brew day consumes about 21kw/h.

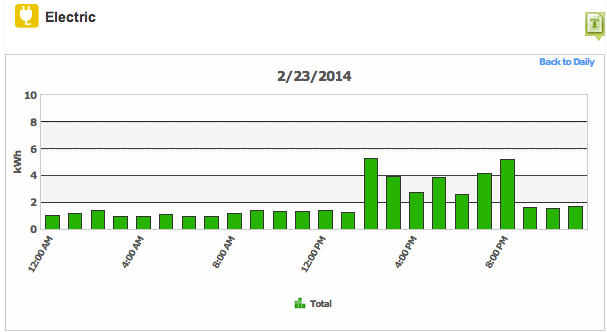

An hour-by-hour Brewday Breakdown looks like this:

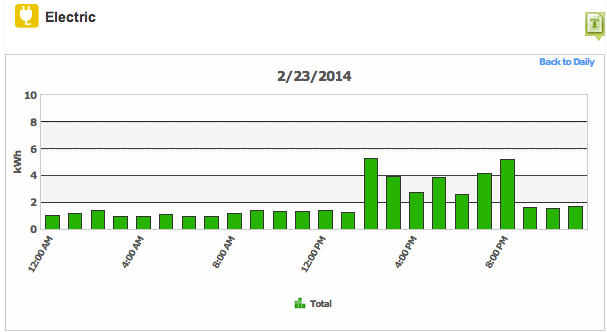

Brewday 1:

Starting to fire the HLT around 2pm, Heating Strike Water and Mashing in around 3pm, and then Boiling around 7pm. (Total process time about 6.5hrs)

NOTE: The first Brewday used a bit more power than our estimated normal because we were pretty slow in our processes as is shown in the graphic.

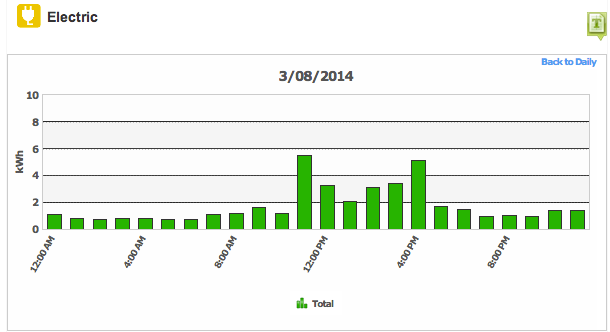

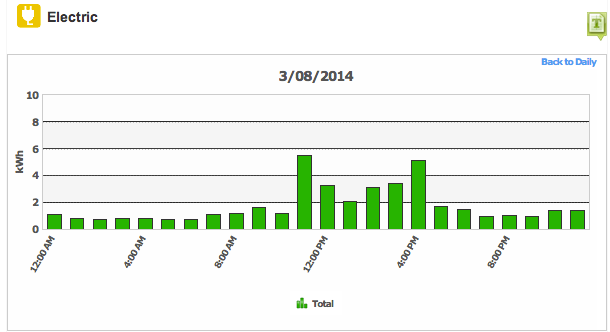

Brewday 2:

Starting to fire the HLT around 10:30am, Heating Strike Water and Mashing around 11:30am, and boiling around 3pm. (Total Process time about 5hrs)

Finally the costs:

With that, we can figure what it costs (roughly) in dollars to run the system for a full batch from cold water to wort into the fermenter.

Total Power Used: 21kw/h

Cost per kw/h (we're on a tiered system, but we'll use an avg): 7.6 cents

Additional costs per kw/h (fees, distribution, etc): 5.3 cents

Actual kw/h cost: 12.9 cents

Which Means we spend about $2.71 per Brewday in power cost. **This does not include the flat fees that we pay each month to keep the electrical service active, because we would have the service regardless of our brewery.

Looking at this, you certainly can't argue too much with the power costs of running the 5500w 30amp system, with the 2 pumps active! I just quickly ran through this, after having a discussion with my co-brewer (brother) about what it was costing to fire the system each time we got together.

Recently, the power company installed these fancy new smart meters that let us do hour-by-hour tracking of our home energy use. Obviously, being a bit of a geek, I was curious what our rough energy use and cost was for a standard Brewday (usually 10gal out of the fermenter).

Here's what I came up with (These are fairly rough calculations for the sake of simplicity).

Baseline Energy Use vs. Brewdays:

From this, we learn a few things. First, on an average day*, we're using about 22kw/h of power for everyday stuff. TV, Fans, Lights, Microwave, Refrigerator etc. On a Brewday, the energy usage increases about 43kw/h of power total.

*NOTE: You'll have to excuse the spikes to around 30kw/h on this graphic before the first brewday, these were days where we were testing the Brewing system (we omitted these from the normal use baseline).

Knowing this, we can assume that our standard brew day consumes about 21kw/h.

An hour-by-hour Brewday Breakdown looks like this:

Brewday 1:

Starting to fire the HLT around 2pm, Heating Strike Water and Mashing in around 3pm, and then Boiling around 7pm. (Total process time about 6.5hrs)

NOTE: The first Brewday used a bit more power than our estimated normal because we were pretty slow in our processes as is shown in the graphic.

Brewday 2:

Starting to fire the HLT around 10:30am, Heating Strike Water and Mashing around 11:30am, and boiling around 3pm. (Total Process time about 5hrs)

Finally the costs:

With that, we can figure what it costs (roughly) in dollars to run the system for a full batch from cold water to wort into the fermenter.

Total Power Used: 21kw/h

Cost per kw/h (we're on a tiered system, but we'll use an avg): 7.6 cents

Additional costs per kw/h (fees, distribution, etc): 5.3 cents

Actual kw/h cost: 12.9 cents

Which Means we spend about $2.71 per Brewday in power cost. **This does not include the flat fees that we pay each month to keep the electrical service active, because we would have the service regardless of our brewery.

Looking at this, you certainly can't argue too much with the power costs of running the 5500w 30amp system, with the 2 pumps active! I just quickly ran through this, after having a discussion with my co-brewer (brother) about what it was costing to fire the system each time we got together.