spankster301

Member

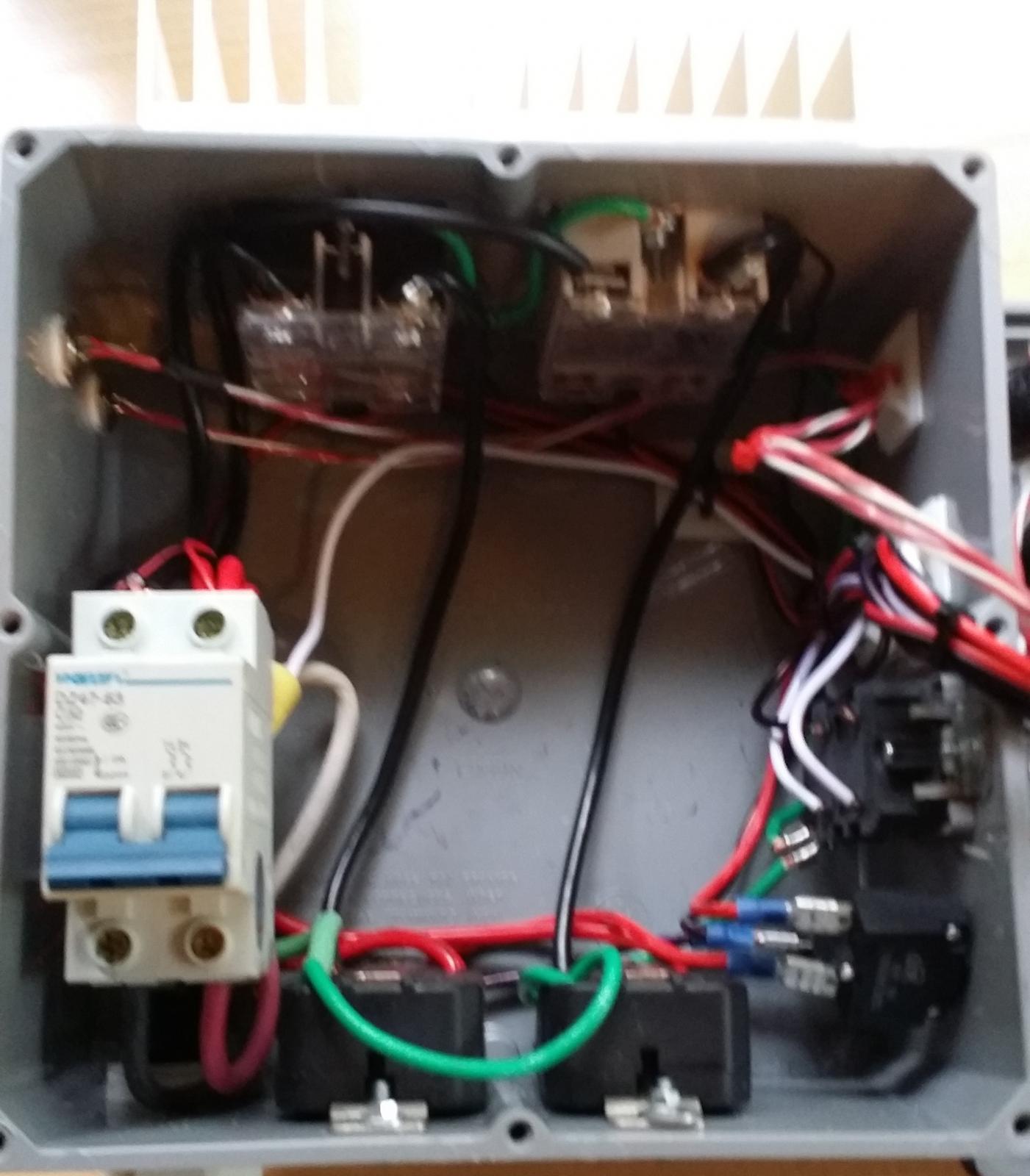

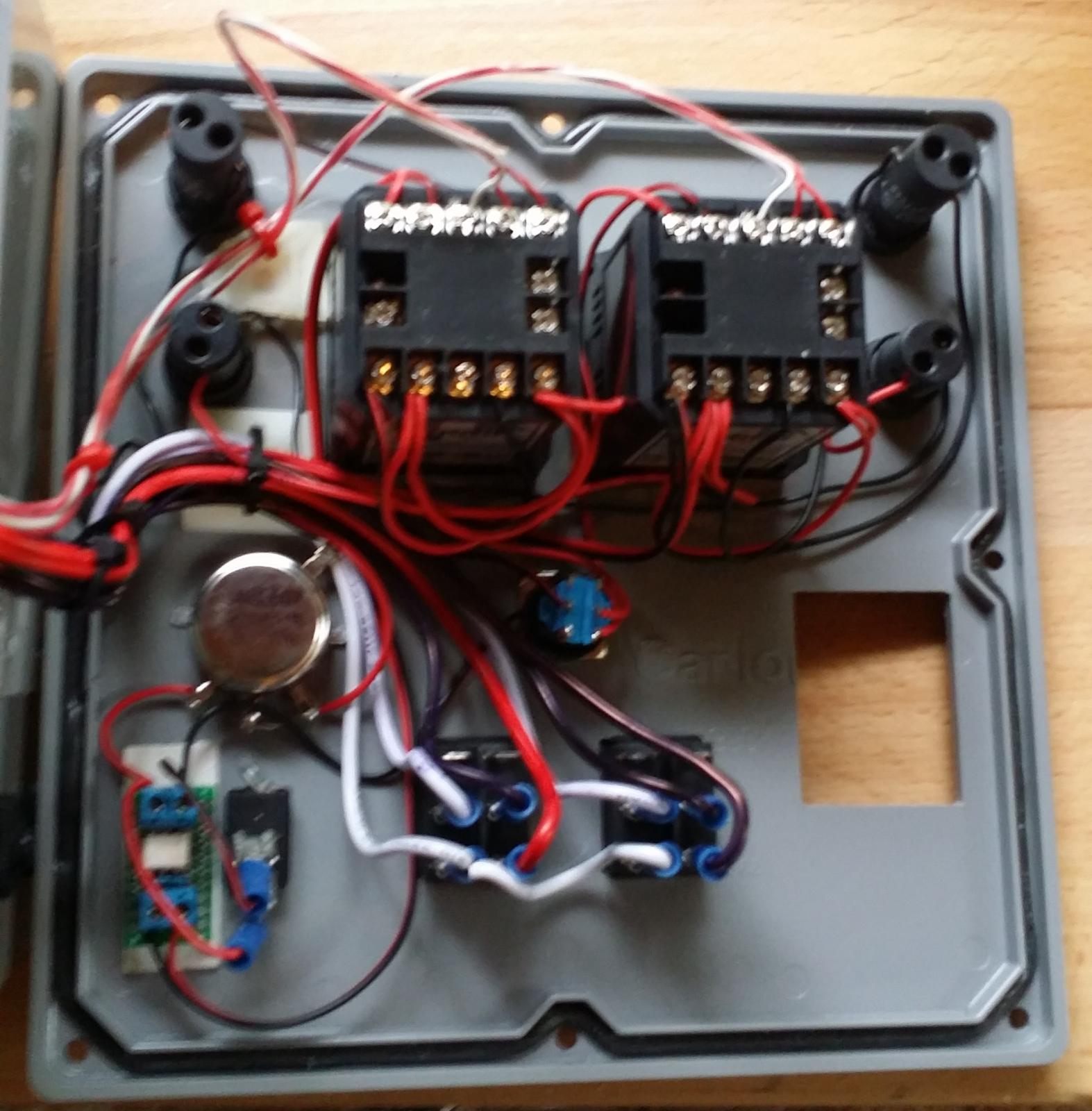

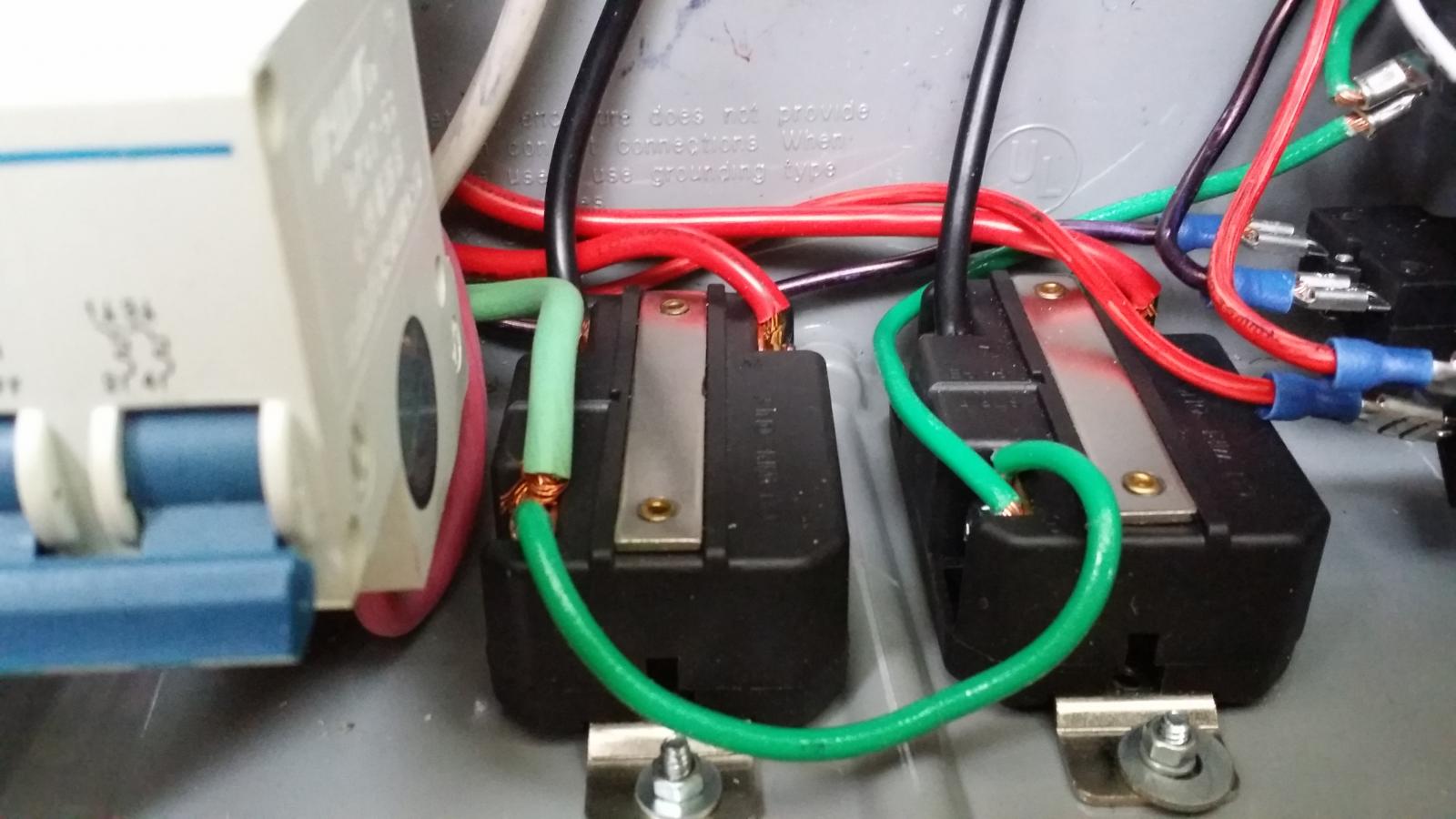

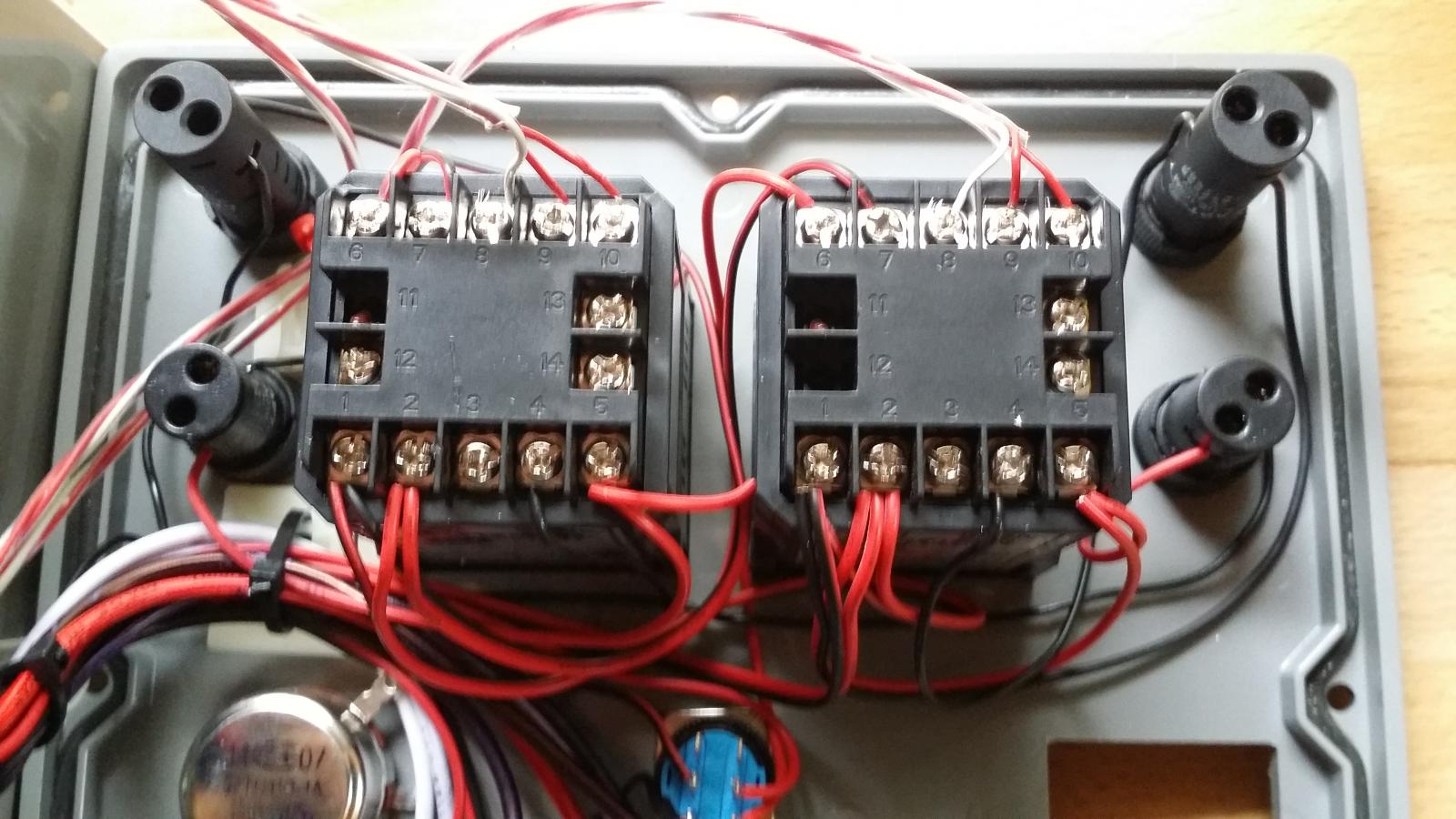

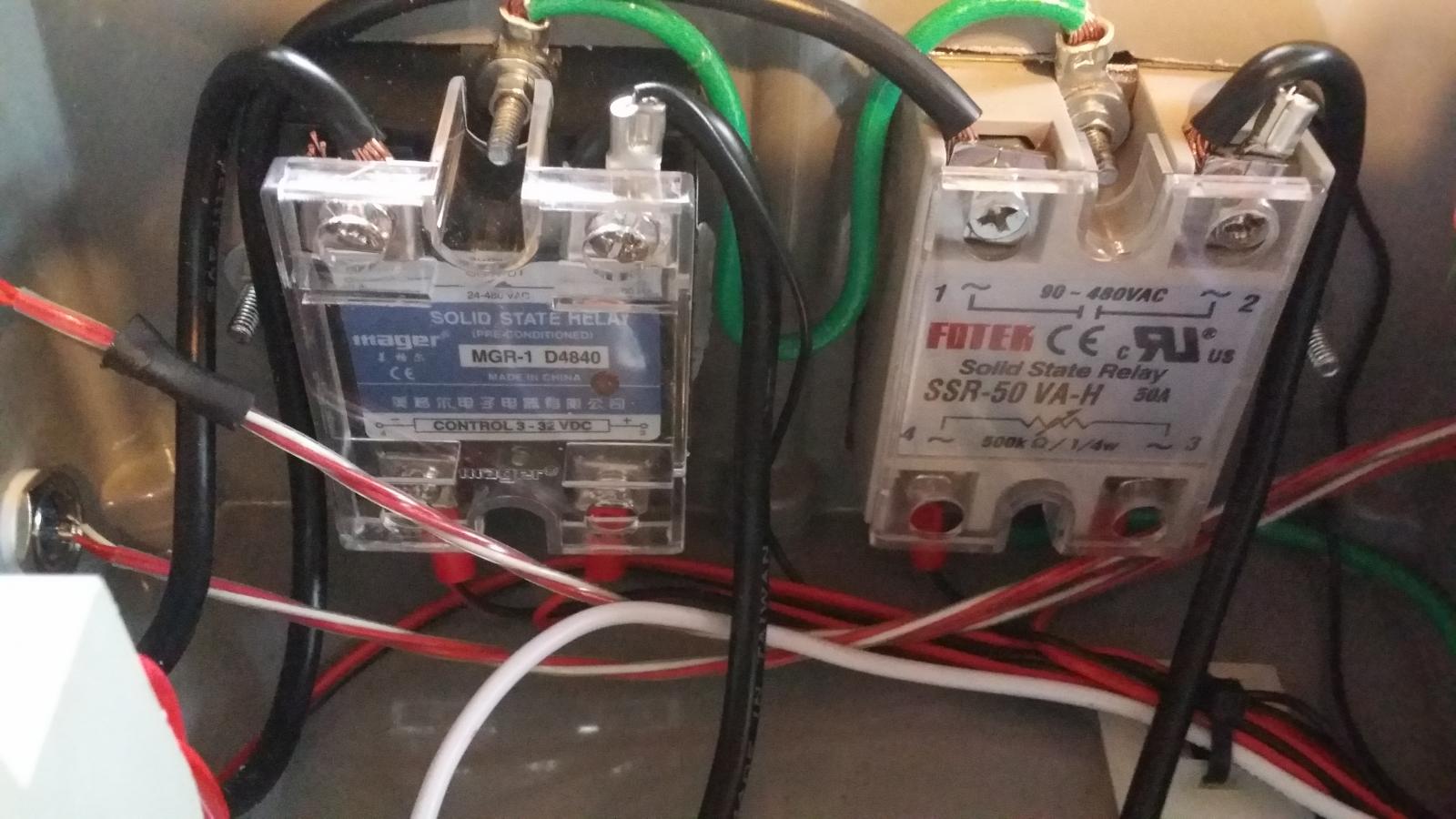

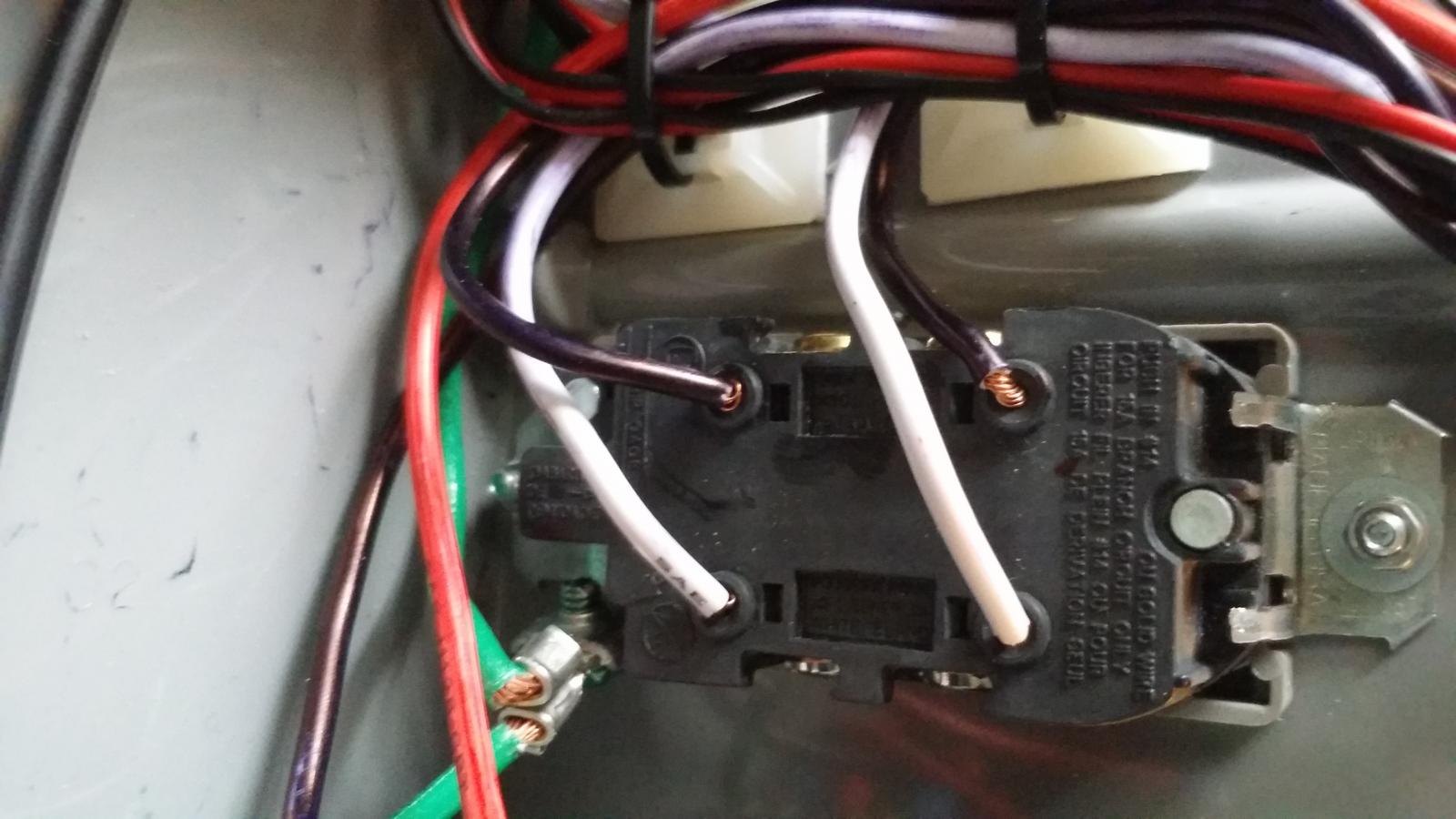

Might be the wrong place for this (Moderator: If so, please move to appropriate location). I purchased this controller (was on a budget) and am having issues. Does anyone know of a company or brewer that can repair this controller? Never worked right from the beginning but I bought it before I was completely set up so the warranty had passed. The pump receptacles never worked and the HLT receptacle stopped working after a couple of brews. Any help would be appreciated.

Last edited: