Spawn-Inc

Member

- Joined

- Apr 14, 2018

- Messages

- 23

- Reaction score

- 16

Started brewing 5 weeks ago and have done 4x 5 gallon batches so far but tired of bottling and got a freezer for free so time to make a keezer!

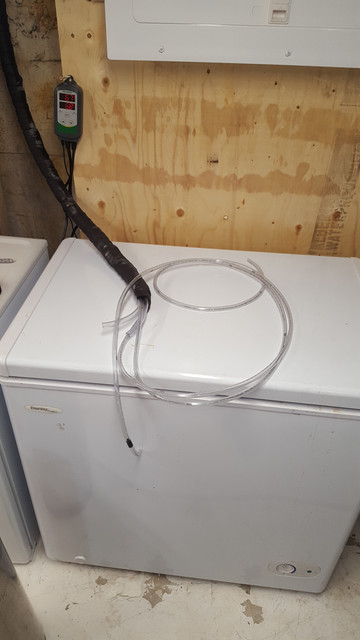

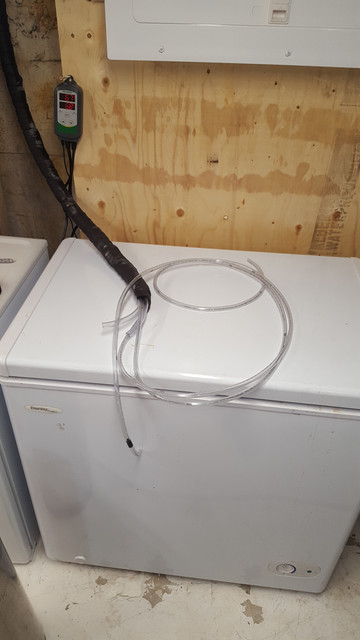

I bought a Inkbird 308 to control temps which is working well so far. I wanted to mount the faucet on my kitchen counter as that's the only place i have space in my house. Being in the HVAC trade i decided to use 2" gas pipe for the tower. I ran two beer lines but am only using one for now. I also ran two 3/8" ID lines to run chilled water through to keep the beer cold. The freezer is in the basement and the tap is on the first floow. I have about 8' height difference and roughly 10' of line between the keg and tap. I double wrapped the beer and cooling lines with 1/4" thick foam tape, hopefully that will be enough. For the cooling lines i will have a bucket of water/antifreeze inside the keezer. I have an aquarium pump that will curculate the water 24/7 to keep the beer chilled in the lines.

Waiting on a co2 bottle fill and for the keg to carb after i get the co2 filled before the beer starts flowing. First beer in the keg will be a session ipa make with 1 pound of hops

(10 oz summit and 6 oz cascade)

(10 oz summit and 6 oz cascade)

Pictures of the build.

Mock up of the final product.

I bought a Inkbird 308 to control temps which is working well so far. I wanted to mount the faucet on my kitchen counter as that's the only place i have space in my house. Being in the HVAC trade i decided to use 2" gas pipe for the tower. I ran two beer lines but am only using one for now. I also ran two 3/8" ID lines to run chilled water through to keep the beer cold. The freezer is in the basement and the tap is on the first floow. I have about 8' height difference and roughly 10' of line between the keg and tap. I double wrapped the beer and cooling lines with 1/4" thick foam tape, hopefully that will be enough. For the cooling lines i will have a bucket of water/antifreeze inside the keezer. I have an aquarium pump that will curculate the water 24/7 to keep the beer chilled in the lines.

Waiting on a co2 bottle fill and for the keg to carb after i get the co2 filled before the beer starts flowing. First beer in the keg will be a session ipa make with 1 pound of hops

Pictures of the build.

Mock up of the final product.

Last edited by a moderator: