Tecumseh 1/3hp 134a C/U $310, filter dryer $18, cap tube $12, XR60CX $111, cbox $17, Tank $63, Lid $23, insulation $32, evap copper 3/8” x 50' $38, 38x12 insulation $0.58 ft, Pig tail $12, electrical crimp ends pack $6, service cord $20, 5 gal glycol 70% w/blue die $63, Sheet metal $40, Steel and wheels guess $50+, zip ties and anchors $10, silicone $6 and …. It adds up, most prices with out tax and only the tank/lid had shipping costs.

Not enough time or $ to make my own tank, vacuum molded fiberglass and inject foam. Found usplastics Tamco 6 gallon tank #5349793 and lid #14563. The square shape should made it easy insulate with Home Cheapo 2”x4'x8” r7.7 Rigid Foam not the Styrofoam bs.

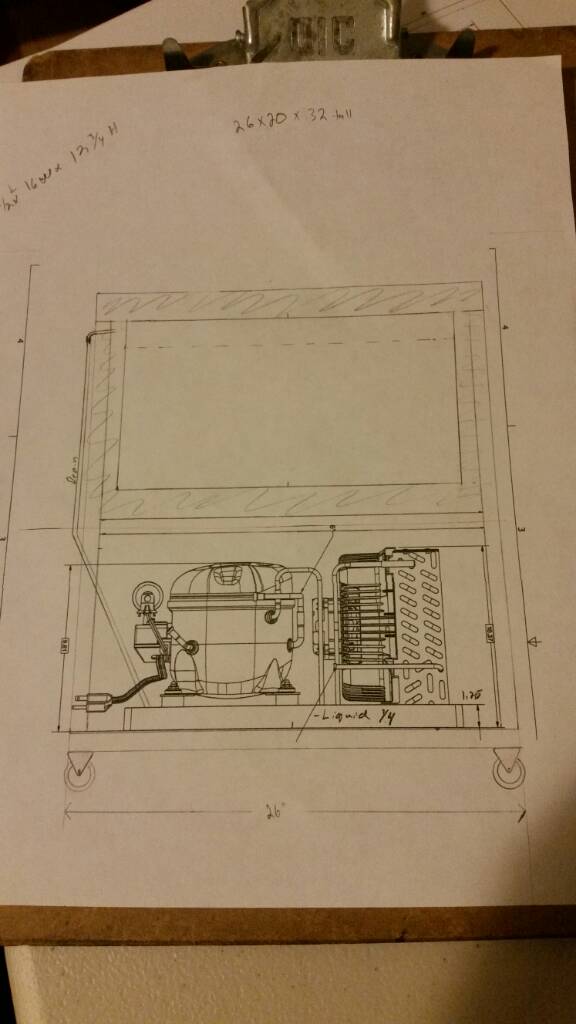

Drew a plan.

Local tin knocker made me a sheet metal box: a base (didn't use) and with two sides.

Base is 1-1/2”x 1/2” rectangle tube and wheels (two strait and two swivel w/ locks), cut and mig welded together.

NO IDEA WHY I changed my mind, but bought a larger tank (10 or 11 gal), insulated and mounted it. Hated it and went back to the original plan. Don't ask why the lid is huge in the pic. Waist of $ and time. ( For Sale by the way)

Back to the plan. Tank in, cut insulation to fit the sides and bottom. Silicone to stop air leaks that cause condensation. I didn't insulate to the top of the tanks lip edge that added an extra 1” of sheet metal hanging out the bottom. Had to make a small cut in the sheet metal but it fit over the steel base to easily screw together.

3/8 refrigeration soft copper is used as the evaporator. It is super easy to bend and super easy to kink. Must be supported at all times when bending or rolling. Hand rolled 50 ft 3/8 soft copper around 4 inch abs with rubber coupler to add more OD. 14 wraps and 14 wraps back over itself, with enough to pipe to the unit.

Don't ask about the beer or outdated calendar of women in waders. Bent the copper to the suction on the compressor, insulate and sweat the cap tube in. Nitrogen purge always when sweating copper to keep the inside clean. 15% Silver will handle high psi no fux needed. Cap tube length and ID is determined by gas, HP and temp range. Trick is to use a wire stripper to score the tube enough and brake it off clean not to influence the ID. I used .040 ID and 79” to target a medium temp range. C/U is rated at high temp. We will see how it goes.

Used a Dixel XR60CX 120v universal controller in a cbox, comes with 2 nickel temp probes (might have to go Stainless). It can interface out to the net, alarms, psi controls and the list goes on... Look at that later. Need to setup temp parameters and the defrost cycle. Defrost to stop ice build up. It does a ton I will never use. Best part there is a hot key to copy and easily load on another controller. Check out xr60 Emerson installation start up pdf.