Hi All,

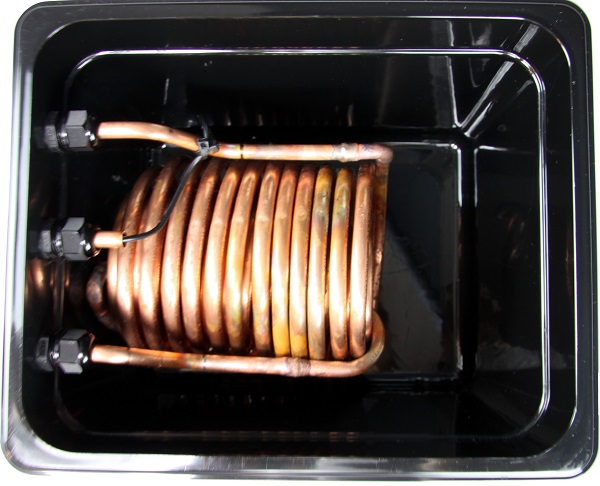

Now that I have a conical I have been looking into a glyco system. I tried the homemade route and ended up ruining the a/c. While trying to bend it to get it into place, I was moving slowly and watching the copper towards the condenser and did not notice it was bending at the other end. Oh well, just 40.00 down the drain. Was going to try again, but no luck finding any more used a/c units so now looking into just taking the plunge. I have been looking at the penguin 1/3 hp one and the Icemaster 100. I have read the reviews and the concerns with some of the issues with the Icemaster 100 but they seem like simple fixes if needed. I like that it is 3/8 hp and the reservoir is 8 gallons. the penguin is just 1/3 hp and reservoir is just 1.25 gallons. My main concern is I will be running in the garage here in Texas and it will get hot so I know during those times any unit will need to run more. I am wondering if the penguin would run less with a smaller reservoir or would the small size make if difficult to keep up with maintaining temps? If you were going to go with either of this, what do you like and why?

I just brew 5 gallon batches. Will have two conicals. Want to start making lagers too.

Thanks for any advice. Just want to make sure going with what makes most sense with the large purchase.

Now that I have a conical I have been looking into a glyco system. I tried the homemade route and ended up ruining the a/c. While trying to bend it to get it into place, I was moving slowly and watching the copper towards the condenser and did not notice it was bending at the other end. Oh well, just 40.00 down the drain. Was going to try again, but no luck finding any more used a/c units so now looking into just taking the plunge. I have been looking at the penguin 1/3 hp one and the Icemaster 100. I have read the reviews and the concerns with some of the issues with the Icemaster 100 but they seem like simple fixes if needed. I like that it is 3/8 hp and the reservoir is 8 gallons. the penguin is just 1/3 hp and reservoir is just 1.25 gallons. My main concern is I will be running in the garage here in Texas and it will get hot so I know during those times any unit will need to run more. I am wondering if the penguin would run less with a smaller reservoir or would the small size make if difficult to keep up with maintaining temps? If you were going to go with either of this, what do you like and why?

I just brew 5 gallon batches. Will have two conicals. Want to start making lagers too.

Thanks for any advice. Just want to make sure going with what makes most sense with the large purchase.