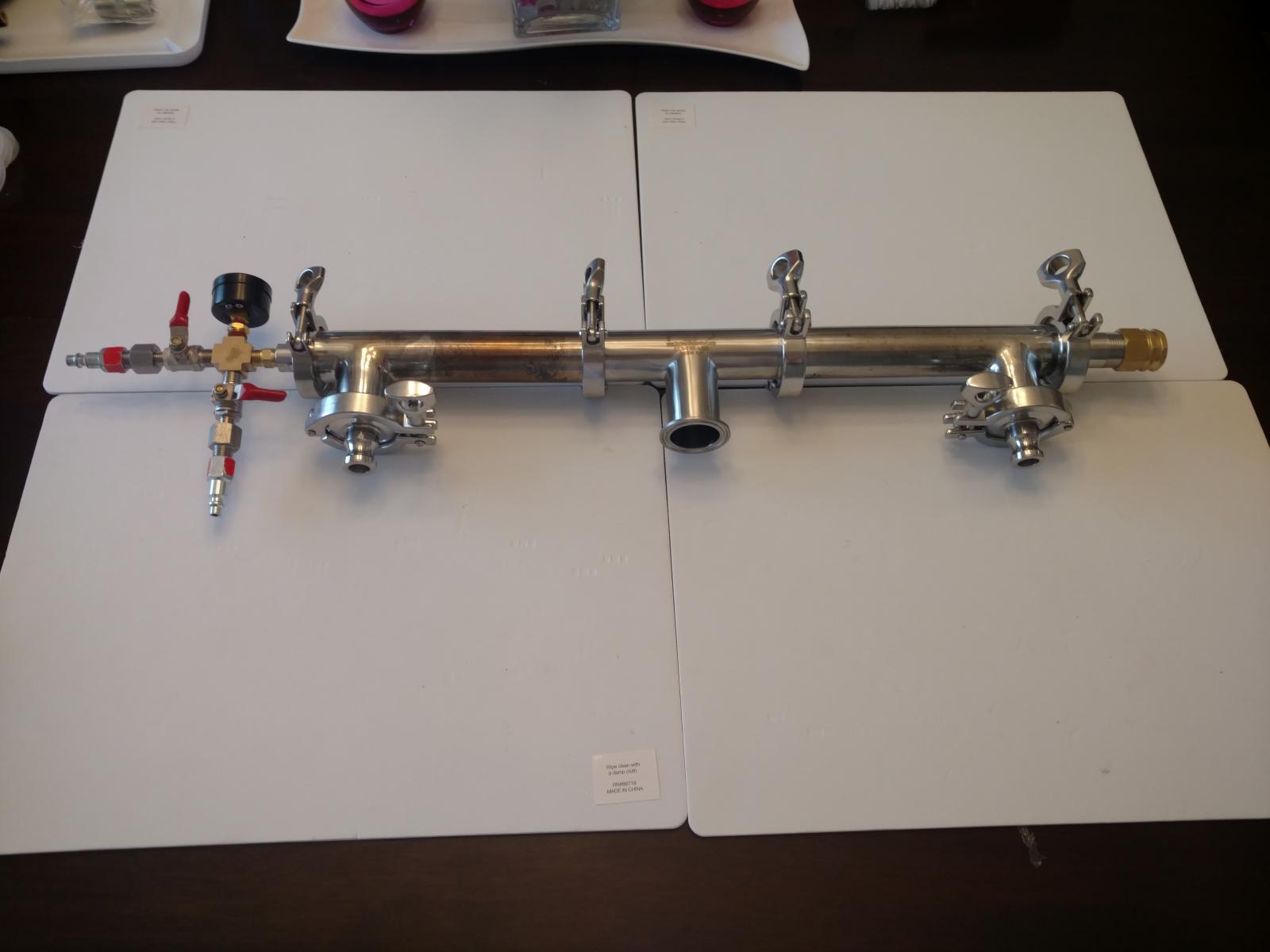

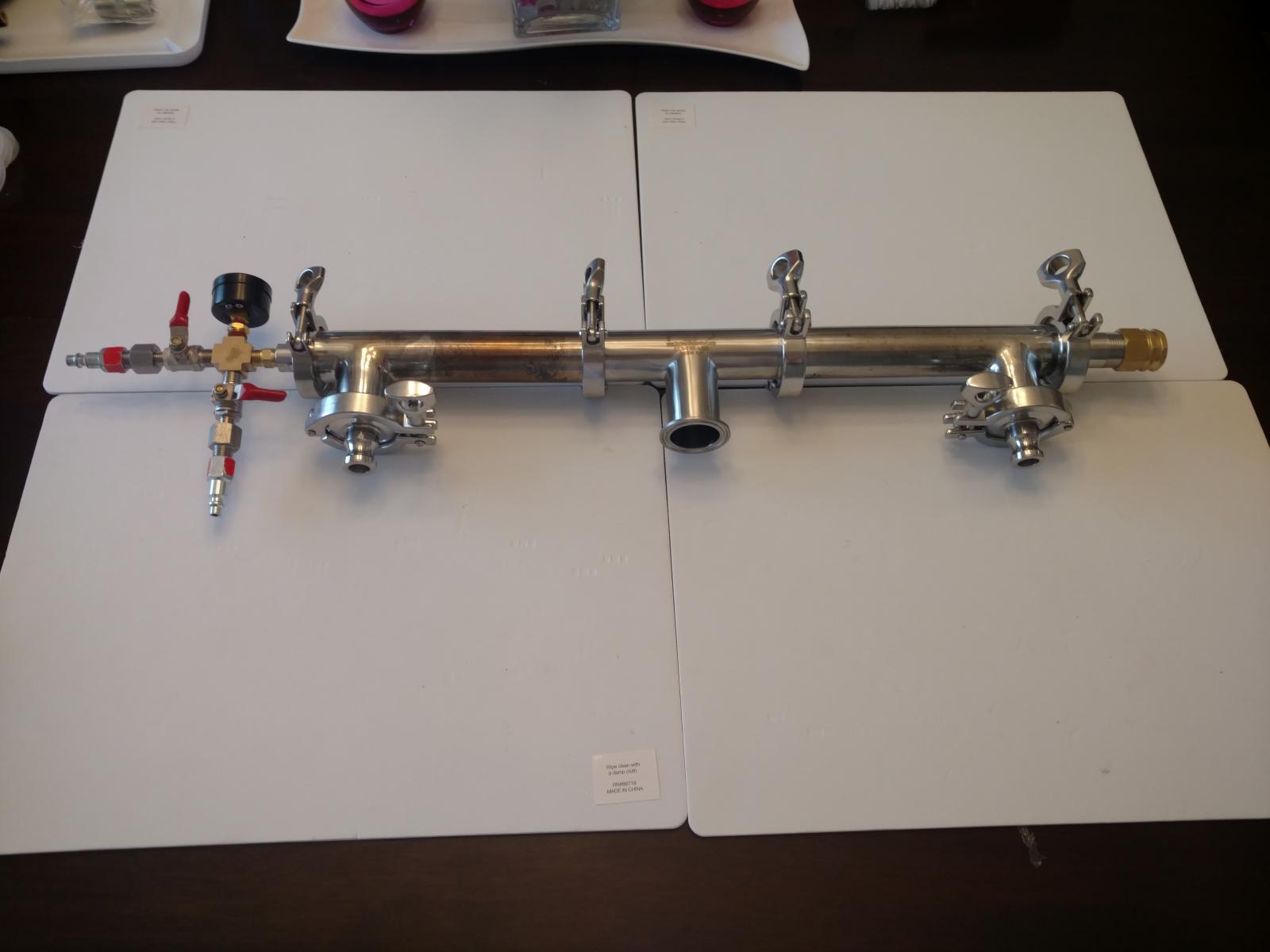

Apparently Snowmageddon is the father of inspiration! While I had my RIMS tube and pump out plumbing them, I thought to myself, "Self, why couldn't you convert your RIMS tube to a sanke keg cleaner?"..... Well, I'm a couple parts short but I think I have a good start!

Now hold on tight and try to follow along!

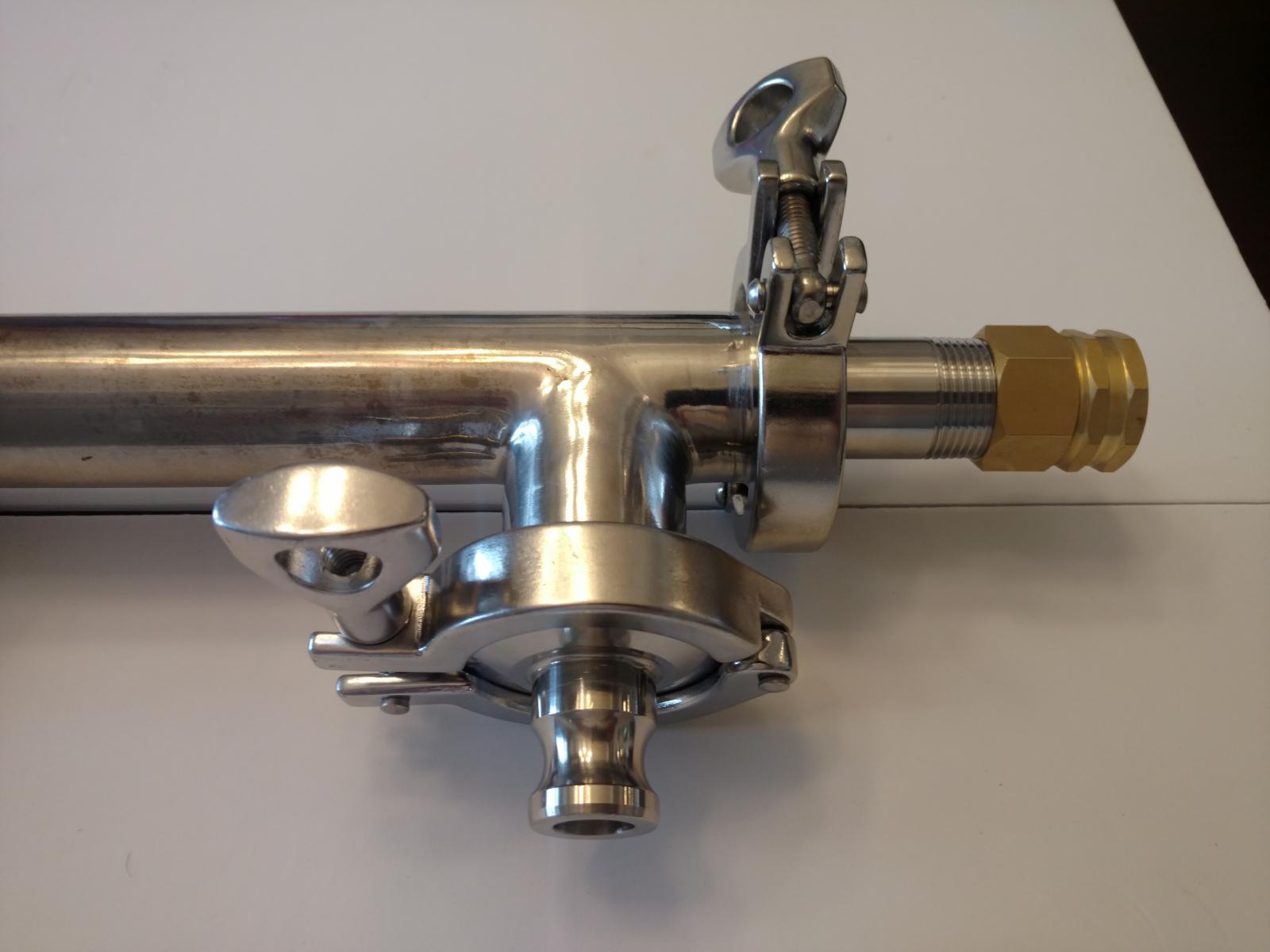

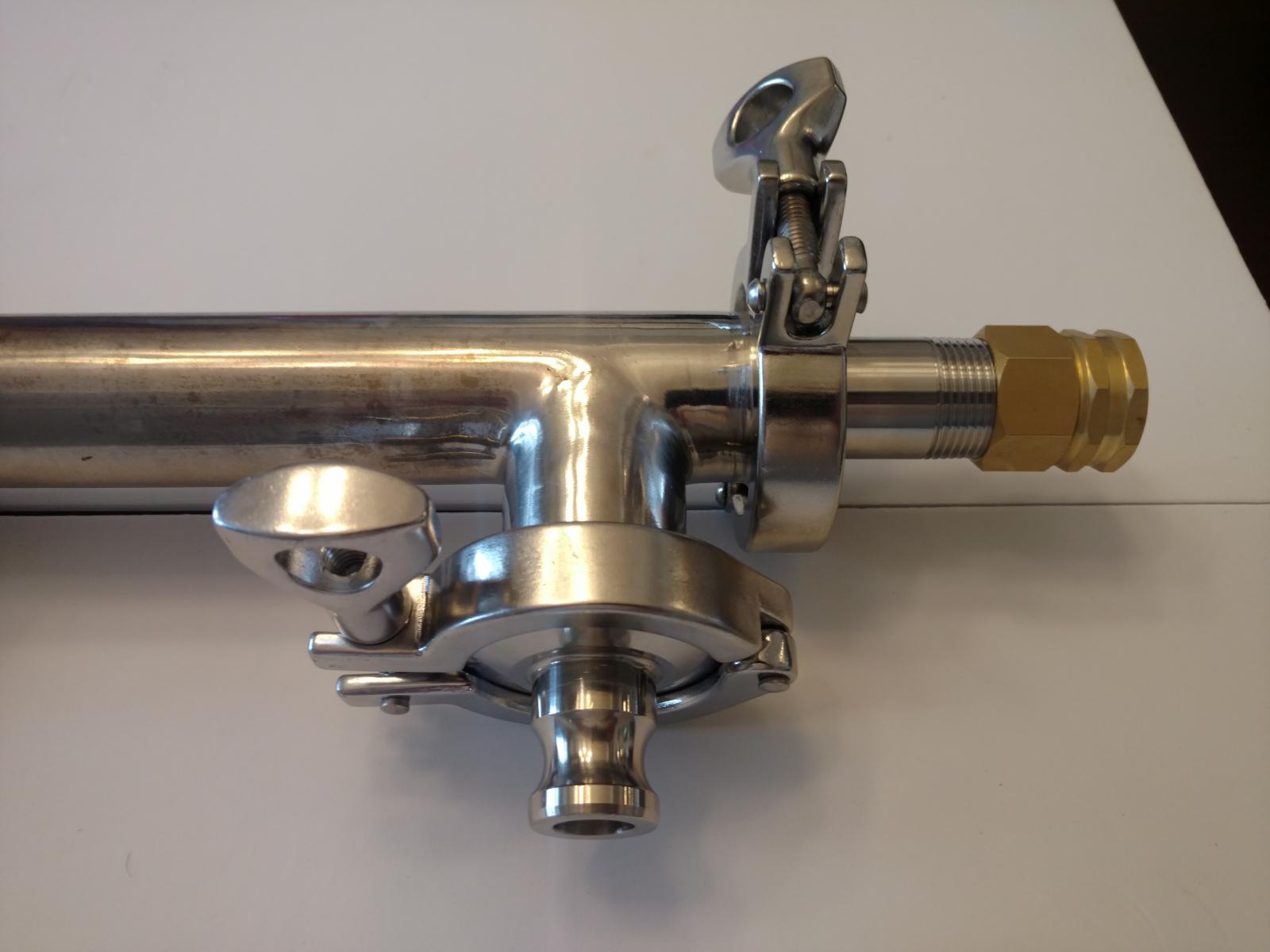

* An air compressor and CO2 line will be attached to the left end of the RIMS tube via quick connects and a garden hose will be connected to the right end.

The keg will be attached to the exit port (center) of the RIMS tube and flushed with water, then purged with air.

Cleaner will enter the pump through lower 3 way valve, exit the pump and be directed to the left cam lock on the RIMS tube. It will exit the tube through the center cam lock (missing) and enter the keg via a modified sanke coupler and return from the keg to the cleaning tank.

The keg will again be flushed with water and purged with air.

Sanitizer will enter the lower 3 way valve, exit the pump and be directed to the right cam lock on the RIMS tube. It will follow the same path through the keg and return to the sanitizer tank.

The keg will then be purged with CO2 and closed off until it's ready to be filled!

So will it work? Suggestions? Too complicated? Overkill? I am concerned that the pressure gauge may not work with gas and liquid and how much CO2 I would be using to complete the final purge of sanitizer.

Now hold on tight and try to follow along!

* An air compressor and CO2 line will be attached to the left end of the RIMS tube via quick connects and a garden hose will be connected to the right end.

The keg will be attached to the exit port (center) of the RIMS tube and flushed with water, then purged with air.

Cleaner will enter the pump through lower 3 way valve, exit the pump and be directed to the left cam lock on the RIMS tube. It will exit the tube through the center cam lock (missing) and enter the keg via a modified sanke coupler and return from the keg to the cleaning tank.

The keg will again be flushed with water and purged with air.

Sanitizer will enter the lower 3 way valve, exit the pump and be directed to the right cam lock on the RIMS tube. It will follow the same path through the keg and return to the sanitizer tank.

The keg will then be purged with CO2 and closed off until it's ready to be filled!

So will it work? Suggestions? Too complicated? Overkill? I am concerned that the pressure gauge may not work with gas and liquid and how much CO2 I would be using to complete the final purge of sanitizer.