BandonBrewingCo

Well-Known Member

Hi,

I want to build a control box for a single vessel system, utilising craftbeerpi. However, my knowledge of electronics is lacking.

According to the wiki what I need is:

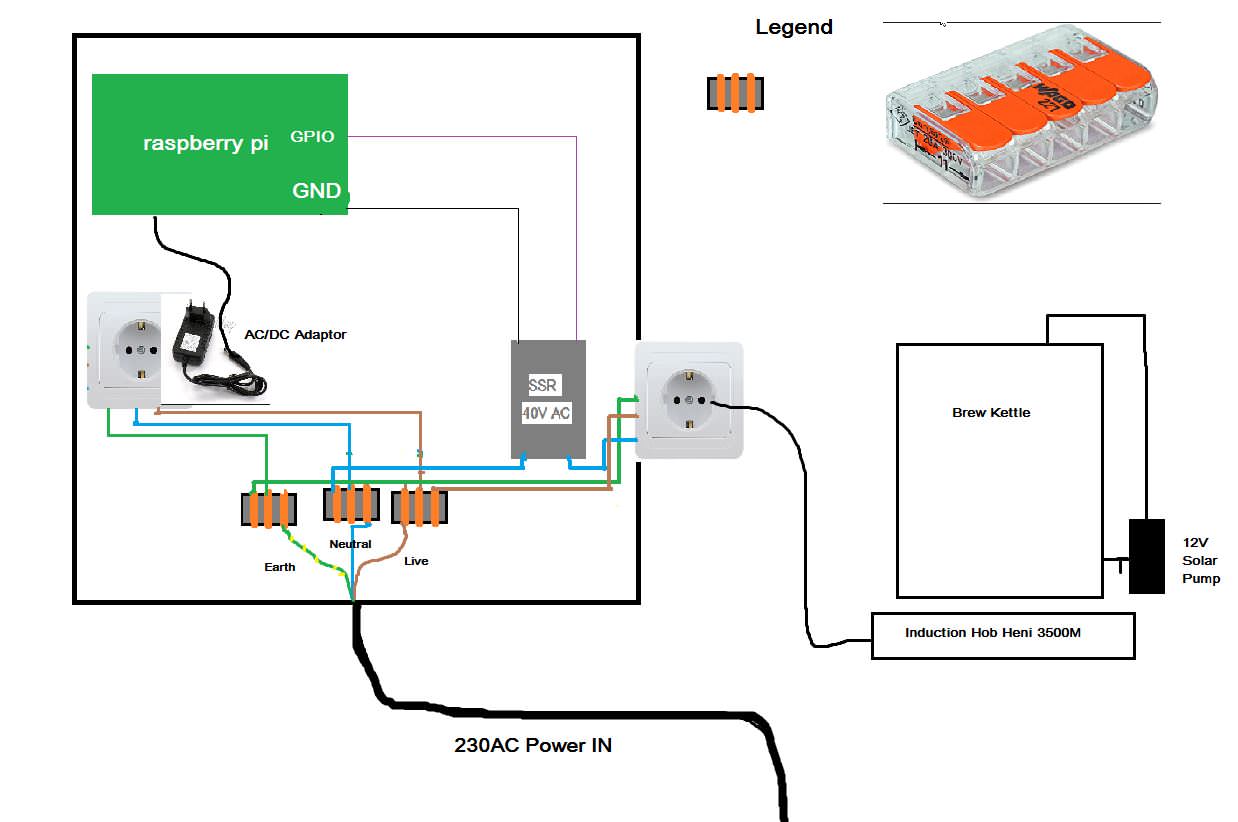

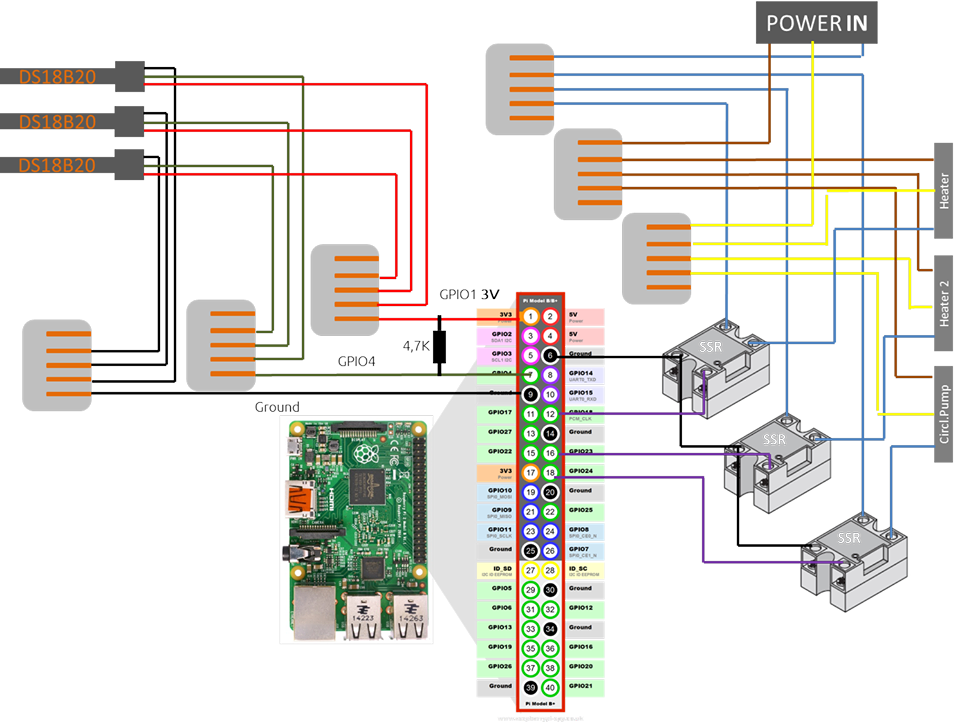

And the wiring looks like this:

Questions:

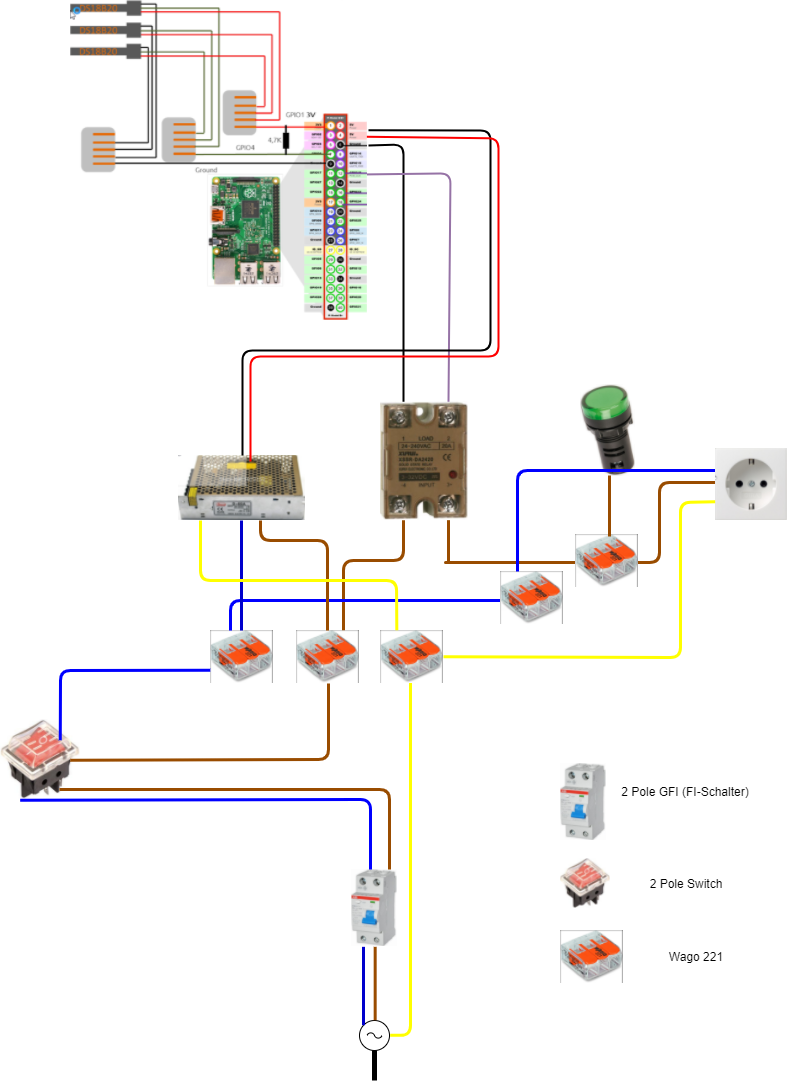

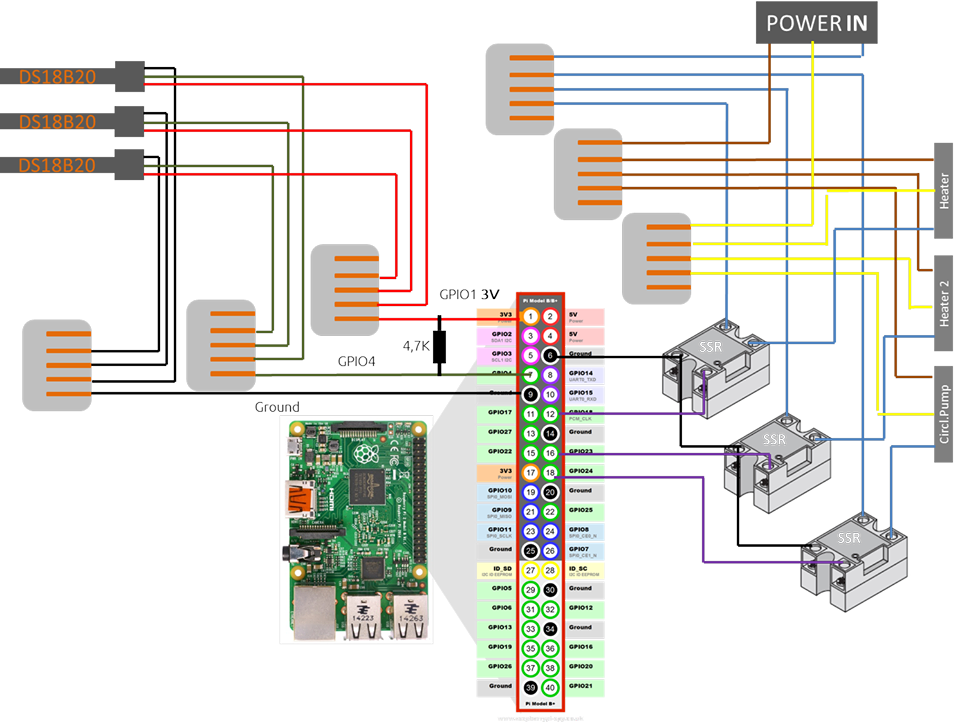

1. What are the grey things with brown stripes on the right hand side? It looks like some sort of thing that takes in one of the 3 mains (European) wires on one side and repeats them out to the SSRs and outputs on the other side. What are these things called? And if they are doing that is each repeating wire carrying up to 240v?

2. Are the ones on the left doing the same thing with pins 1, 7 and 9? Are these the same parts if they are?

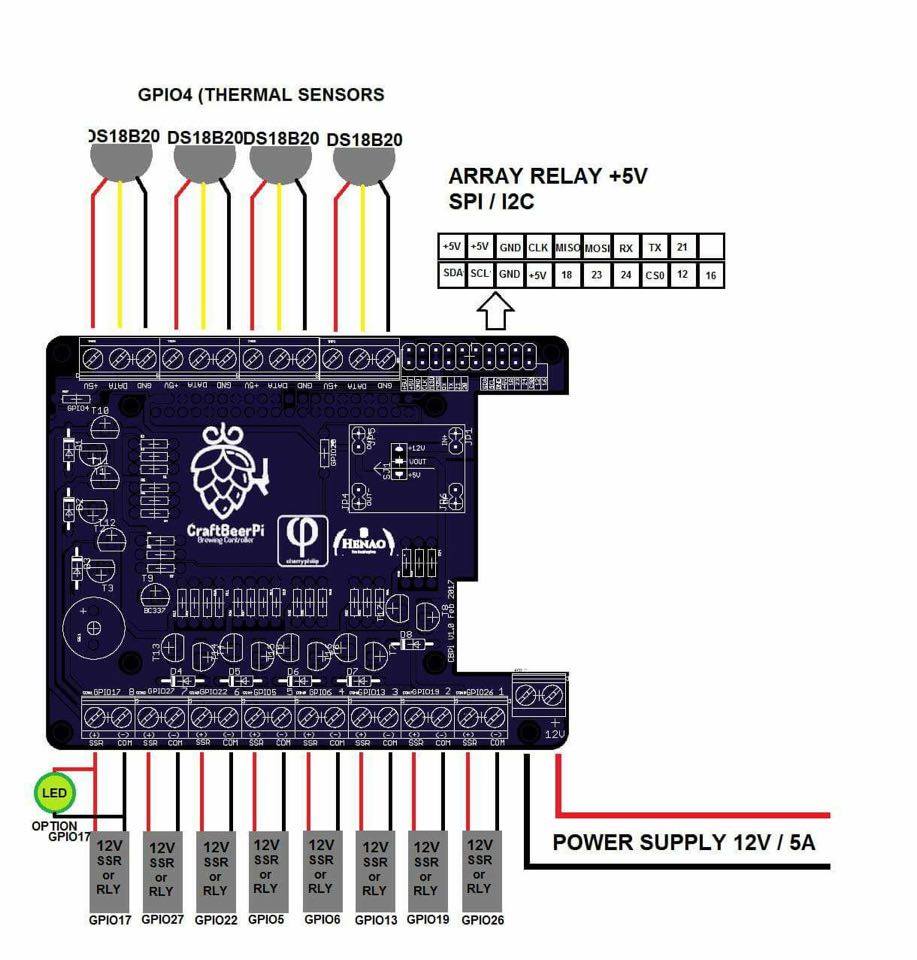

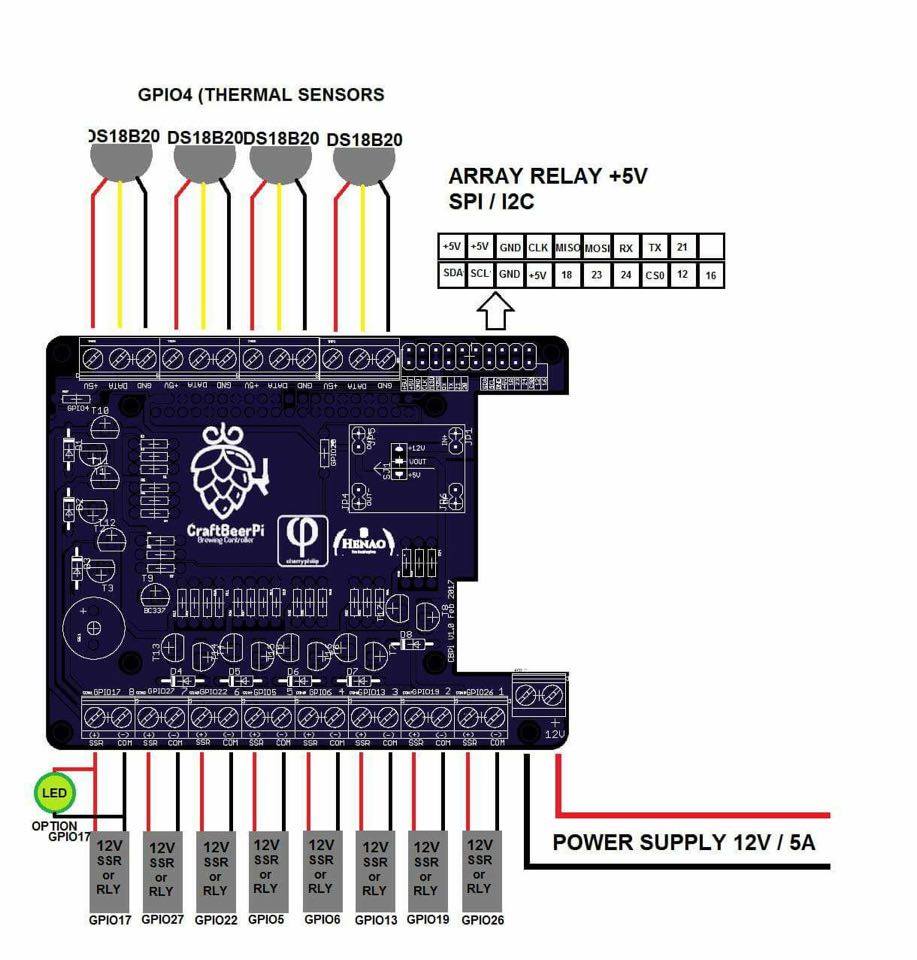

3. What would be the advantage to using the extension board? And where is the third wire for the power supply gone? Also, are the relays on the bottom for SSRs? (I'll be driving a Hendi 3500W Induction Hob).

Many thanks!

I want to build a control box for a single vessel system, utilising craftbeerpi. However, my knowledge of electronics is lacking.

According to the wiki what I need is:

- Raspberry Pi (all models is supported)

- 1 x 1-wire Temperatursensor DS1820 Waterproof! + Thermowell stainless steel

- 1 x 4.7k Ohm Resistor

- Jumper Cable

- Solid-State Relais XURUI + Heatsink KAB-60 (for each actor you need one relay)

And the wiring looks like this:

Questions:

1. What are the grey things with brown stripes on the right hand side? It looks like some sort of thing that takes in one of the 3 mains (European) wires on one side and repeats them out to the SSRs and outputs on the other side. What are these things called? And if they are doing that is each repeating wire carrying up to 240v?

2. Are the ones on the left doing the same thing with pins 1, 7 and 9? Are these the same parts if they are?

3. What would be the advantage to using the extension board? And where is the third wire for the power supply gone? Also, are the relays on the bottom for SSRs? (I'll be driving a Hendi 3500W Induction Hob).

Many thanks!