In systems based on Braumeister water is pumped from the bottom of "vessel inside a vessel" and overfills on top. This is kind of checked and efficient way of sparging, nevertheless, I would like to share with you of my small concept - but I'm not experienced and just asking if it is worth to give a shot.

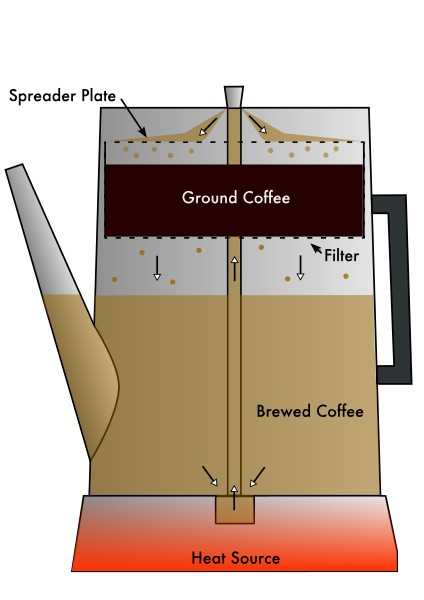

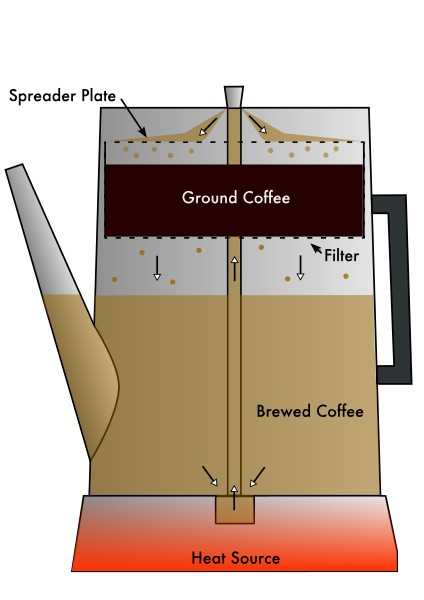

There are coffee percolators everywhere, and this post is going to focus mainly on phenomena of precolation. To clarify, you can review this site on Wikipedia and refer to the picture below.

An element heats water in main vessel, which is transported together with bubbles of air through vertical pipe to Spreader plate, form where it is spread on Ground coffee. With force of gravity water goes downwards extracting some substances from coffee grains and becomes coffee. At next, coffee drips form the filter located at the bottom of small "basket" in which milled grains of coffer are kept in. Since mixture of coffee/water on the bottom of main vessel is constantly heated, the liquid cycles.

This concept, after some modifications, could be used to do a fly sparge, which could mean an increase of efficiency towards usage of Stainless Steel Braid, mainly since liquid used to sparge after couple of cycles contains some sugar. The sketch of my concept can be seen below.

Here pump comes in handy, since liquid used to sparge has 78 °C, so it could be difficult to transport it using bubbles, or am I wrong?

I know it may be similar to RIMS/HERMS at the first view, but there you have a constant stream of liquid coming through grain bed, so concentration of sugars in sparging liquid sets on average levels (because it is lower on the top and higer on the bottom and mixes easily). During percolation, liquid which has contact with grain bed is separated from lower concentration liquid, which helps to extract sugars from grain bed.

Technical question is, if liquid will keep up with extracting and going downwards before the one on the bottom of main vessel runs out?

Please, feel free to comment and criticise, since some of my thoughts may be wrong, but still - it has some scientific background.

There are coffee percolators everywhere, and this post is going to focus mainly on phenomena of precolation. To clarify, you can review this site on Wikipedia and refer to the picture below.

An element heats water in main vessel, which is transported together with bubbles of air through vertical pipe to Spreader plate, form where it is spread on Ground coffee. With force of gravity water goes downwards extracting some substances from coffee grains and becomes coffee. At next, coffee drips form the filter located at the bottom of small "basket" in which milled grains of coffer are kept in. Since mixture of coffee/water on the bottom of main vessel is constantly heated, the liquid cycles.

This concept, after some modifications, could be used to do a fly sparge, which could mean an increase of efficiency towards usage of Stainless Steel Braid, mainly since liquid used to sparge after couple of cycles contains some sugar. The sketch of my concept can be seen below.

Here pump comes in handy, since liquid used to sparge has 78 °C, so it could be difficult to transport it using bubbles, or am I wrong?

I know it may be similar to RIMS/HERMS at the first view, but there you have a constant stream of liquid coming through grain bed, so concentration of sugars in sparging liquid sets on average levels (because it is lower on the top and higer on the bottom and mixes easily). During percolation, liquid which has contact with grain bed is separated from lower concentration liquid, which helps to extract sugars from grain bed.

Technical question is, if liquid will keep up with extracting and going downwards before the one on the bottom of main vessel runs out?

Please, feel free to comment and criticise, since some of my thoughts may be wrong, but still - it has some scientific background.