ayupbrewing

Well-Known Member

- Joined

- Nov 26, 2012

- Messages

- 150

- Reaction score

- 13

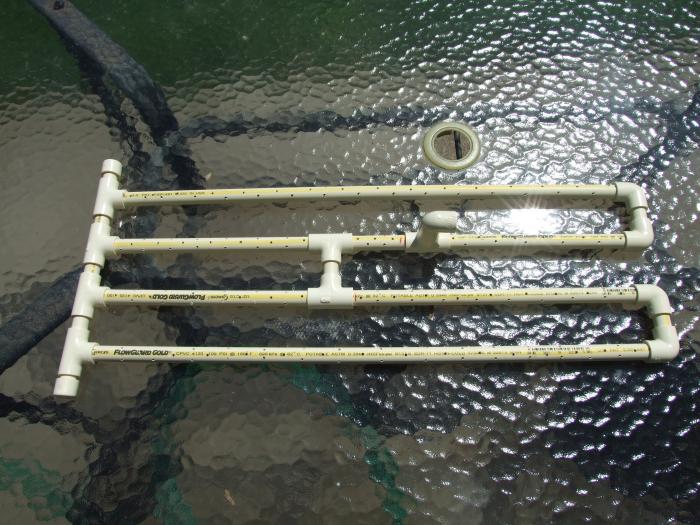

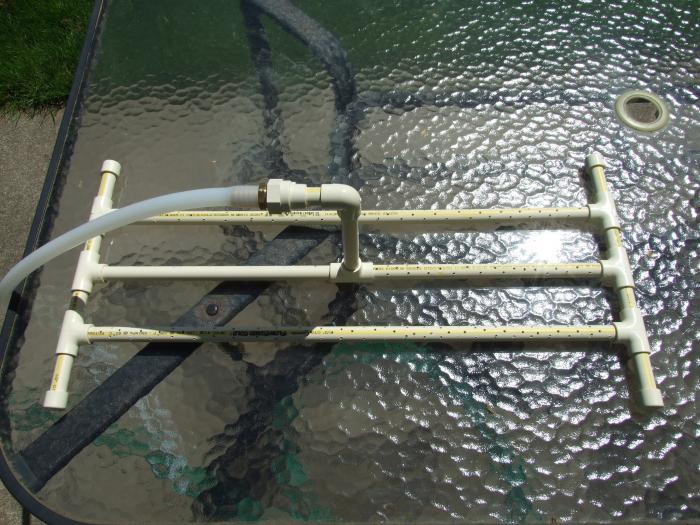

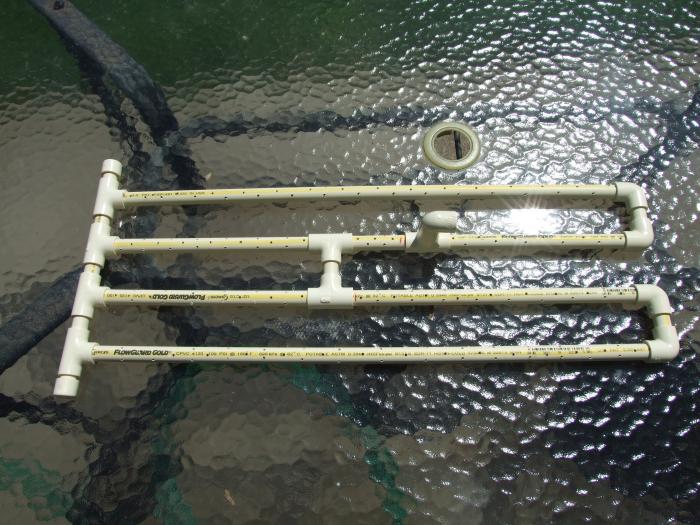

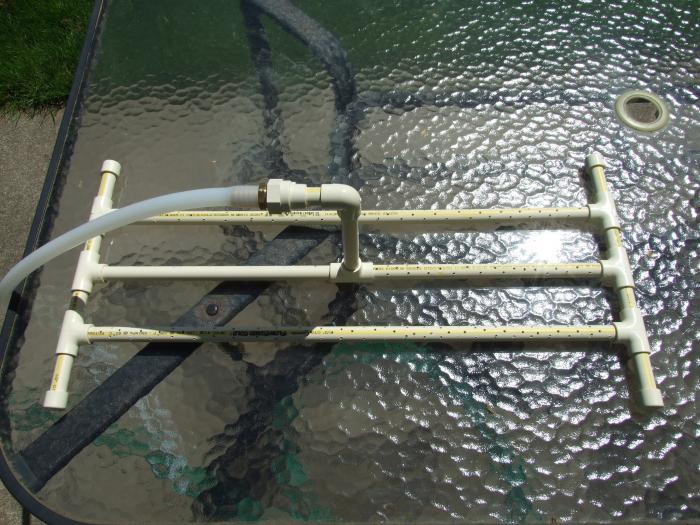

Here are pics from my mash tun build...its a 70quart coleman cooler with CPVC manifold and sparge arm. Silicon tubing is used to connect the HLT to sparge arm and from the cooler outlet to the BK with an inline valve to control flow to the BK. I used brass barb fittings. I also used a foil covered piece of polystyrene that sits on the ridge halfway down the inside of the cooler to reduce headspace and reflect heat.