OK, So I happened to be considering the same thing and had an old coffee maker that I saved for this or a similar purpose...

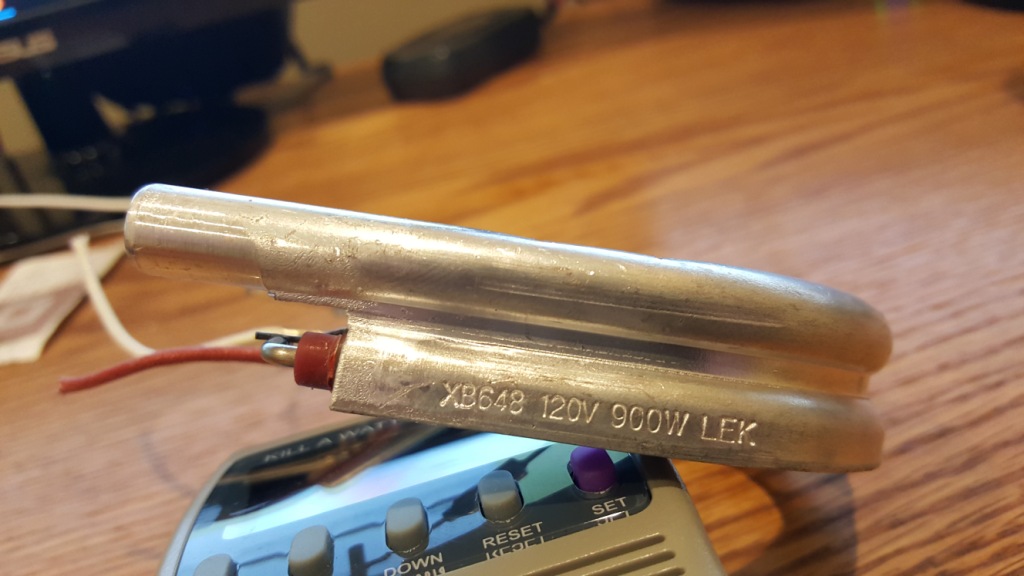

The heating element I have is a 900 watts protected/controlled by a klixon set to 145°C(293°F). It has an active length and a star shaped cross section inside. The total perimeter of the tube is ~1", though I imagine that the star profile is to increase turbulence and promote better heat transfer to the water. As the length of the tube is only about 8" pressure drop is minimal for moderate flow rates ~.1psi at 2l/min

I checked power usage and flow rates by running a batch of water through my coffee maker to get a better idea of what is actually happening.

I stuck my thermometer down the output to verify the temperature is around boiling, as it is, ~97°C (207°F). Measured flow rate is .198L/minute, which matches the expected value for a 1kW element and 80°C temperature rise.

At full power, it will do ~16°C (29°F)/(L/minute)

If you run 2L/minute you can have a reasonable temperature rise across the element and most likely have no scorching as you will be cooling the element below the boiling point of the wort, since flow is turbulent and well mixed.

Actual power density is somewhere around 125 watts/in^2 but with forced flow, scorching should not be a problem.

If you do go this route, I would probably leave the temperature switch on it and possibly wire it into a kill circuit for safety in case a pump stalls or something and the element starts running dry.

I hope that made enough sense...