Alright guys, as usual I am way behind, and I am sure this has been beat to death but.... On my last brew I pulled a sample from the fermentor and was really excited, there was a complex hop flavor that disappeared once it was on tap. My method of transfer is to pull the airlock, hook a hose to the outlet and drain into a keg with the hose in the bottom so no splashing. I realize I am introducing oxygen to the fermentor as well as in the keg. Using that method am I losing my hop flavor?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Closed Transfer.

- Thread starter sodbuster

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Mar 10, 2021

- Messages

- 2,793

- Reaction score

- 2,411

Probably. What you are describing isn't a closed transfer.

I suspect you will find people that say they follow your process and make excellent hoppy beers, and other that say any amount of oxygen will turn any hoppy beer to a purple oxidized mess.Alright guys, as usual I am way behind, and I am sure this has been beat to death but.... On my last brew I pulled a sample from the fermentor and was really excited, there was a complex hop flavor that disappeared once it was on tap. My method of transfer is to pull the airlock, hook a hose to the outlet and drain into a keg with the hose in the bottom so no splashing. I realize I am introducing oxygen to the fermentor as well as in the keg. Using that method am I losing my hop flavor?

Are you purging the headspace well after filling? I am not sure how many fill-purge cycles are needed to get down to reasonable oxygen levels. As long as the keg is fairly full, it is not a lot of headspace that needs to be purged.

A few years ago I moved to doing closed transfers into purged kegs. I have been tempted to try a split batch with one keg filled like your process, and one filled with a closed transfer. I guess I know that oxygen is harmful to hoppy beers, so I would rather just spend the extra $1 worth of CO2 and the extra 15 minutes and do a purge and closed transfer for all my beers.

I would also look at your entire process. If you remove a bucket lid a few times to take gravity readings and add dry hops, then the little bit of oxygen picked up during the transfer is probably not the biggest source of oxidation.

Thanks @CascadesBrewer i cram the kegs full and purge, also I use a conical so the beer is only exposed to o2 when I keg. Your final comment has me wondering if it’s worth the hassle.

- Joined

- Oct 12, 2020

- Messages

- 2,187

- Reaction score

- 2,785

It's a matter of perspective and goals... If your goal is just to make beer, and how it tastes isn't important, that's fine.. If you want a specific taste though, please don't think of the labour of reducing or eliminating O2 as a 'hassle' when for some specific brews, ie: hoppy beer, it is a necessity. There's plenty of methods and threads on here for the purging of kegs and O2 free transfers. Take the time to find one that works for you and you'll be rewarded for your efforts.Thanks @CascadesBrewer i cram the kegs full and purge, also I use a conical so the beer is only exposed to o2 when I keg. Your final comment has me wondering if it’s worth the hassle.

I'm a bit confused. You ferment in a conical. You keg. You purge. So you're doing most of the hard parts of minimizing O2 exposure but you think doing a closed transfer from FV to keg is too much hassle?

Hey, you have to draw a line somewhere! At a minimum I would need another co2 tank and regulator. I mostly make ales that are intended to be IPAI'm a bit confused. You ferment in a conical. You keg. You purge. So you're doing most of the hard parts of minimizing O2 exposure but you think doing a closed transfer from FV to keg is too much hassle?

Not necessarily. You could just gravity feed from FV to keg and return gas from keg to FV. You're undoing a lot (most?) of the good of purging the keg by opening the FV to transfer.At a minimum I would need another co2 tank and regulator.

- Joined

- Oct 12, 2020

- Messages

- 2,187

- Reaction score

- 2,785

Since you already have one CO2 tank and regulator, it could be worth your time to just put a spare line on it for utility purposes, such as purging. Since you already gravity-feed your transfers, the only harware additon to your fermenter needs be a ball lock post on the lid, perhaps in place of the airlock. You can then connect the gas post on the recieving keg to the gas post on the fermenter for a closed-loop transfer.Hey, you have to draw a line somewhere! At a minimum I would need another co2 tank and regulator. I mostly make ales that are intended to be IPA

Just a thought.

..here's the cost:

https://www.brewhardware.com/product_p/bulkheadblg.htm

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

Absolutely it works. Only caveat is you can't push much hops matter through there. At least in my experience. Pull mostly clean beer or you're gonna have a bad day. Closed transfer would be the way to go, though. @CascadesBrewer is right that if you're opening the lid after you reach terminal then you're oxidizing it anyway. If you're brewing mostly IPAs then the answer can't be to throw up your hands on that, though, or you're probably never going to love them.@mac_1103 I never thought about filling the keg through the ball lock... that works?

Figure out an oxygen free way to pull samples and add dry hops or just always dry hop before terminal so the yeast can scavenge the O2. Do a closed transfer and be sure to purge all your lines before starting that transfer. Again, if you're brewing IPAs then figuring out ways to do those things is probably going to make the single biggest difference in your beer. For example, getting high quality hops is great...but it doesn't matter if the beer gets oxidized.

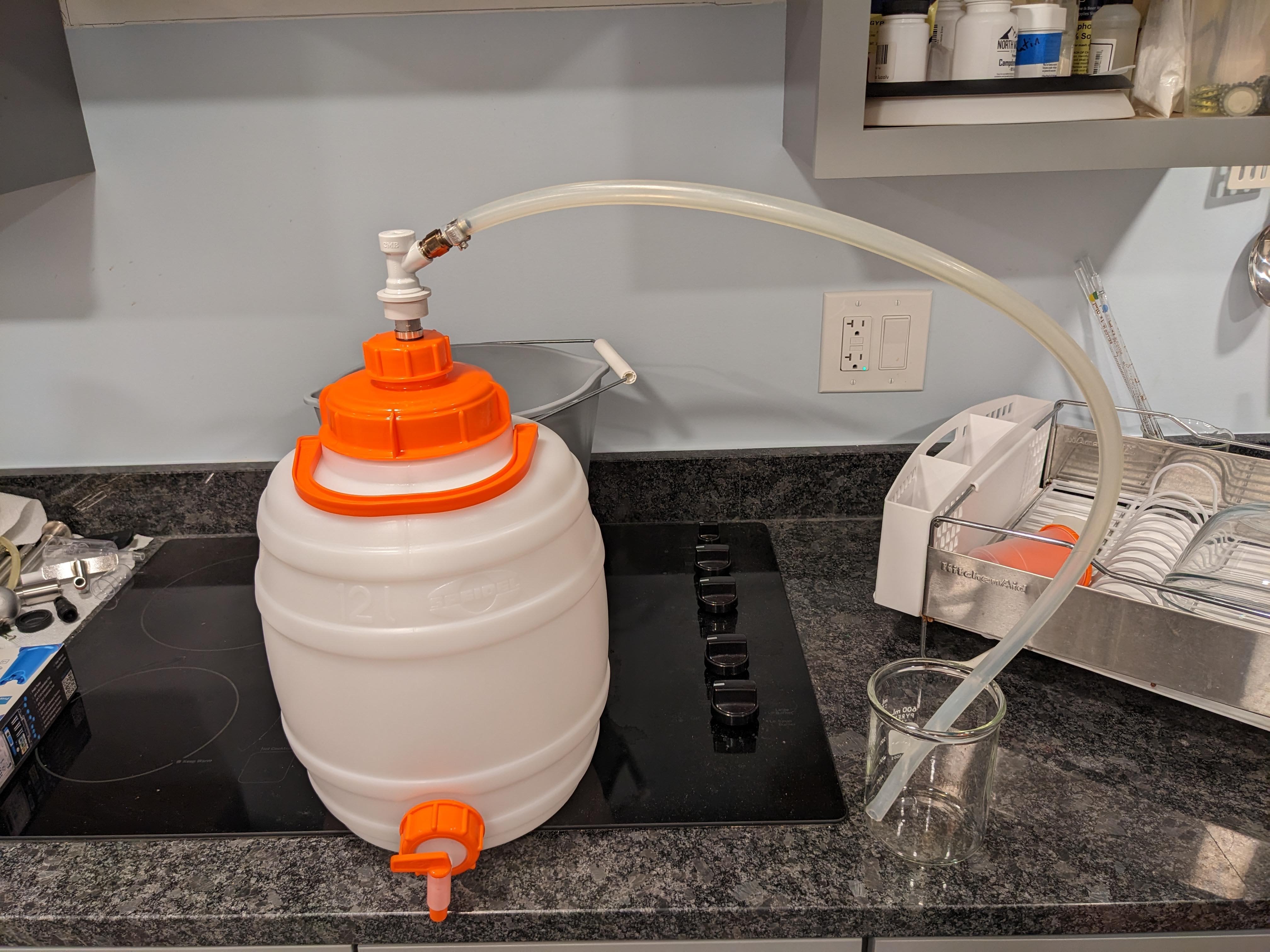

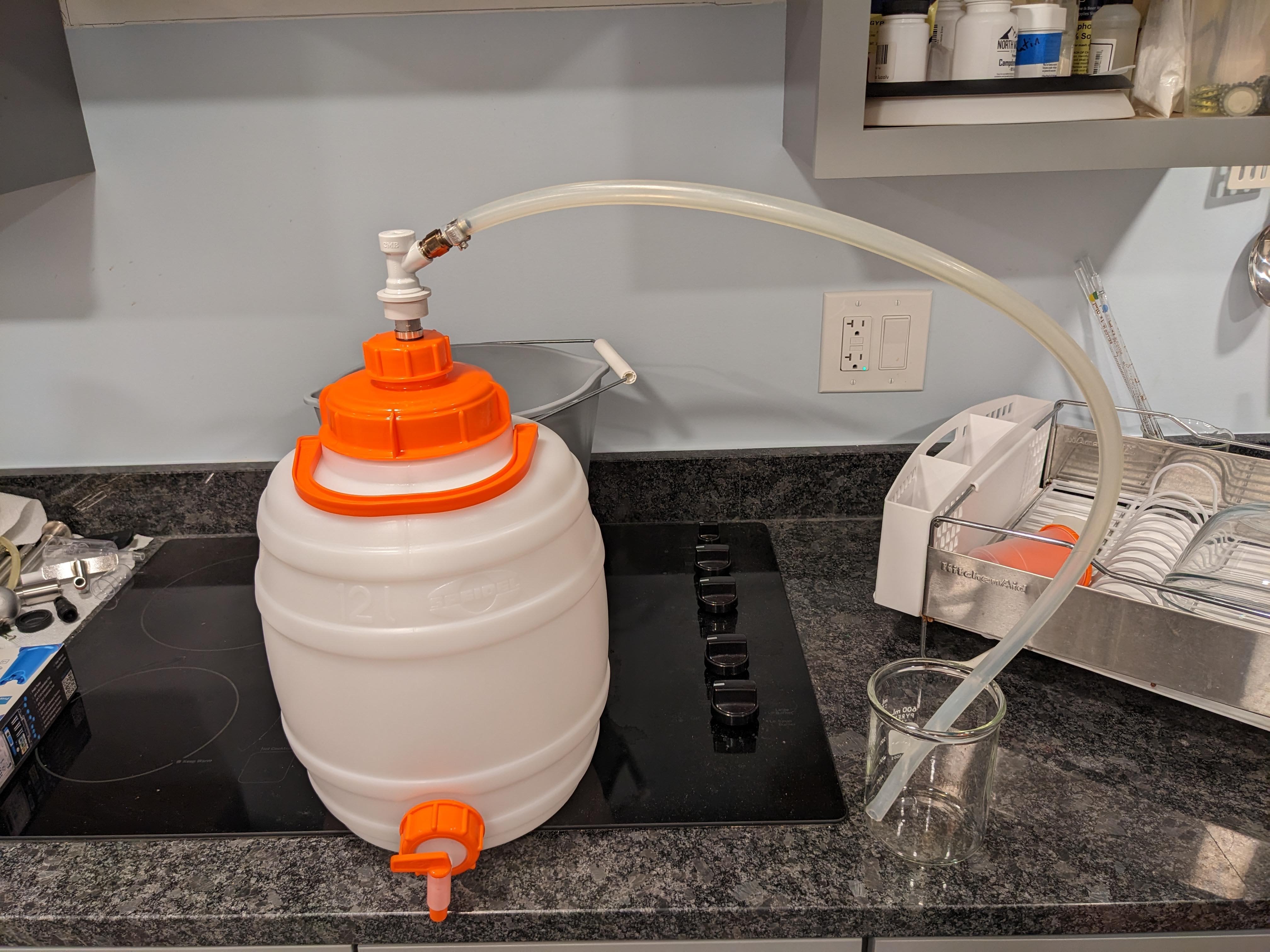

I started out closed transfers by drilling a hole in a speidel cap, the little lid that screws onto the hole where the bung and airlock would go. I put a ball lock post on that. You can run a blowoff from the top post into a bucket for fermentation. Then pop that when done and do a closed loop from the spigot to the keg for liquid and then from the keg to the top post on the speidel for gas.

- Fill the line from the spigot to the liquid out post with sanitizer

- Purge the gas line from the keg before hooking to the fermentor

- Then hook up gas to fermentor first to pressurize the headspace

- Then purge the liquid line into a cup to clear sanitizer

- Hook liquid to the keg and you're off to the (pretty slow) races.

redrocker652002

Well-Known Member

I am sure my way is the most rudimentary, but I simply unhook the ball lock from my gas line on my CO2 can, and push it thru the bung at the top of me bucket. I add a small amount of gas to the bucket, just enough to see the lid bulge a bit, connect the spigot of my bucket to my out post on my keg and open. The keg has been sanitized with starsan and is purged and full of CO2. I open the PRV valve on the keg, open the spigot and let the beer flow. I am thinking of grabbing another used keg and trying to ferment in the keg and do a closed transfer from fermenting keg to serving, but so far, that is what has worked. But, in contrast, I have seen may, Including Claw Hammer and others, just run a line into the keg from the fermenter and let gravity do it's thing. I think sometimes I over complicate things when I don't have to. RR

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

Don't we all?I think sometimes I over complicate things when I don't have to

Yes. Already explained better than I could have.@mac_1103 I never thought about filling the keg through the ball lock... that works?

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

I mocked up the setup I used to do and took some pics to supplement those steps I mentioned. First is for fermentations with blowoff. Then I pop off that blowoff hose, clean and sanitize it, change QDs, and it becomes the liquid line for my closed transfer. Fill it with sanitizer and clamp it on. It took me a couple rocky transfers before I got my SOP ironed out but then it worked like a charm. Still do it for some beers. The speidel will hold a couple PSI so I use a spunding valve to drop it down to about that amount. You can purge the CO2 line from the keg with the CO2 that's in the keg. Then hook it all up. GAS FIRST. It's slow but it works.

thanks @eliastheodosis nice visual.

- Joined

- Oct 12, 2020

- Messages

- 2,187

- Reaction score

- 2,785

Ok... Awkward... But I'm gonna say what a lot of readers are thinking;Thanks guys. I will try it on a few batches. My only hesitation is that I rarely clean kegs and I also make 3-5 batches in my conical before clean out, so sanitation would be key.

Maybe that's where your flavour is going. You should really wash and sanitze your kegs between uses.

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

We all learn as we go, so no need for it to be awkwardMaybe that's where your flavour is going

Everything you read so far about oxygen is totally true and can/will kill hop flavor. If we're reading your post right then not cleaning and sanitizing your fermentor/kegs could also easily be causing you some flavor problems. My guess is that it's still not why your hop flavor is disappearing. I still bet on the oxidation. You're mixing a lot of old yeast, trub, and hop matter from those previous batches into the fresh IPA you're brewing, though. That's almost surely going to affect the flavor. The more you let it go the more likely it's going to turn into some thing worse like a full blown infection. Let us know if we're off base here.

Even though I'm betting on oxidation being the problem I would still definitely address the cleaning and sanitizing first. If you want to make the cleaning easier then make sure your processes are tight. Rinse everything before it dries off. Make sure you have the tools handy to break stuff down and rinse it all right away. Then soaking stuff in some PBW and a light wipe are usually all you need. Nobody on here cleans/sanitizes because it's fun. We all do it because it's necessary!

I can't argue against cleanliness. I don't have any off flavors either. I know this is completely against brewing rules but here we go... as for the kegs, I keep empty ones in the kegerator or keezer until they are ready to fill, my whole thought process on kegs is they stay in a fridge so mostly safe from infection. As for the conical, I will clean and scrub everything, sanitize with starsan, then ferment a beer. after a week or so I dump the top valve to clear the dead yeast, then when I keg I dump a bit more of the dead yeast out and fill the kegs. Take the lid off and throw another batch of beer on top of the remaining yeast, sanitize the lid and gasket and were off. After about 4-5 batches I will break it down and start all over. This is another reason I wanted accurate readings on a hydrometer so I can see if the yeast is losing any of its punch. If I dry hop in the conical I use a bag, same with the keg.We all learn as we go, so no need for it to be awkward@sodbuster he's making a good point, though, and he's saying it to help.

Everything you read so far about oxygen is totally true and can/will kill hop flavor. If we're reading your post right then not cleaning and sanitizing your fermentor/kegs could also easily be causing you some flavor problems. My guess is that it's still not why your hop flavor is disappearing. I still bet on the oxidation. You're mixing a lot of old yeast, trub, and hop matter from those previous batches into the fresh IPA you're brewing, though. That's almost surely going to affect the flavor. The more you let it go the more likely it's going to turn into some thing worse like a full blown infection. Let us know if we're off base here.

Even though I'm betting on oxidation being the problem I would still definitely address the cleaning and sanitizing first. If you want to make the cleaning easier then make sure your processes are tight. Rinse everything before it dries off. Make sure you have the tools handy to break stuff down and rinse it all right away. Then soaking stuff in some PBW and a light wipe are usually all you need. Nobody on here cleans/sanitizes because it's fun. We all do it because it's necessary!

I have brewed for many years but never really captured the hop flavor and aroma that I am after. Closest I got was dry hopping in the conical, but it only seemed to last through the first couple beers. Hopping the keg and I had a grassy flavor, too much.

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

Well, others may be less chill about this but I'm not aware of any actual rules here and I'm certainly not the brewing police. If you don't have any off flavors and it seems to work then you do you. Personally, I brew so many different styles with different flavor profiles and different yeasts that it would be a train wreck if I tried to do this. Again, if it works for you then it works for you!I don't have any off flavors either. I know this is completely against brewing rules

All of that still shouts oxidation to me. If you're cool with the rest of your process and don't think that's it then I'd go back to the O2. What you're describing is what I experienced before I tightened my protocols around oxygen. A nice hop flavor to start and then it slips between your fingers and is gone. I've hopped in bags and commando. You'll get better utilization without bags but if you bump the amount of hops some then a bag can still give you the result you want. Bags are not the reason you're getting no hop flavor. Especially if it's there to start and then falls off. Honestly, diminishing hop flavor points to one thing in my mind. I'll give you a single guess...If I dry hop in the conical I use a bag, same with the keg.

I have brewed for many years but never really captured the hop flavor and aroma that I am after. Closest I got was dry hopping in the conical, but it only seemed to last through the first couple beers

Thanks @eliastheodosis. I can see that you would need to clean out if you are constantly changing beers and yeasts... though I would probably just dump the trub out the bottom and pitch a new, lol.

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

There is something to fit everybody with this hobby. I'd prefer to help you enjoy it than try to tell you what to do or something. You're not me anyway so I see no harm in agreeing to disagree on some stuff

Many brewers I know only brew using kits so they don't have to think about recipes. I never saw the fun in that. I made my own from day one because it seemed pointless to me otherwise. Not following a recipe at all sounds like more art than science...and I see no problem with that at all. You just find your happy place. I see dmtaylor is helping you out in that other thread too.

Good luck and cheers

Many brewers I know only brew using kits so they don't have to think about recipes. I never saw the fun in that. I made my own from day one because it seemed pointless to me otherwise. Not following a recipe at all sounds like more art than science...and I see no problem with that at all. You just find your happy place. I see dmtaylor is helping you out in that other thread too.

Good luck and cheers

Thanks man. ignorance is bliss. The beer I caught and lost the hop flavor on..

24lb 2row

1lb flaked oats

2lb of Crystal 20

2lb of wheat

4oz of chinook 1hr

4oz of cascade 20min

flagship A07 yeast

Went old school on the hops.

24lb 2row

1lb flaked oats

2lb of Crystal 20

2lb of wheat

4oz of chinook 1hr

4oz of cascade 20min

flagship A07 yeast

Went old school on the hops.

Is this batch dry hopped? One of the changes I made to get more hop character in my IPAs was...surprise...use more hops! For a 5 gallon batch of an American IPA, I am usually using around 9 to 10 oz of hops, with about 5 oz late in the boil or at flameout and another 4 oz in a dry hop charge. For a more classic APA or IPA, I like the character from an addition in the 15 to 10 minute range. For a more juicy character, I will move those hops to a hop stand.Thanks man. ignorance is bliss. The beer I caught and lost the hop flavor on..

My current go to IPA recipe was inspired by some Racer 5 clones that I found, but I have increased the hopping rate a bit.

I suppose you could just brew small batches and drink them real fast.All of that still shouts oxidation to me. If you're cool with the rest of your process and don't think that's it then I'd go back to the O2. What you're describing is what I experienced before I tightened my protocols around oxygen. A nice hop flavor to start and then it slips between your fingers and is gone.

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

Also, that's 29lbs in the grist bill... The breakdown looks right so I'm assuming that's NOT a five gallon batch. Otherwise, you might have just a sliiiight efficiency problem24lb 2row

1lb flaked oats

2lb of Crystal 20

2lb of wheat

I would roughly agree with the numbers that @CascadesBrewer gave above. I probably push a little more of the hops into the dry hop and a little less in the whirlpool but not by much. I sprinkle maybe an ounce in at 5 and 15 each and then add whatever at 30 to adjust the IBU and add a little more complexity. Probably about 1.5-2oz there. Mix and match for the later additions to maximize the potential from each hop. Google the survivables chart and check that out if you're interested in this. Centennial carries over some great compounds that survive boiling and fermentation and show up in the final beer. Some other hops do too. Some other hops don't. Chinook is not super high on the list and cascade is even lower. I would say push those hops a little later and blend with another hop like Centennial. The 2022 Hop and Brew School presentation gives a really beautiful, clear breakdown of these survivable compounds and what flavors they can bring to your beer.Is this batch dry hopped? One of the changes I made to get more hop character in my IPAs was...surprise...use more hops! For a 5 gallon batch of an American IPA, I am usually using around 9 to 10 oz of hops, with about 5 oz late in the boil or at flameout and another 4 oz in a dry hop charge. For a more classic APA or IPA, I like the character from an addition in the 15 to 10 minute range. For a more juicy character, I will move those hops to a hop stand.

Even for a five gallon batch I would say that's not very high for overall hops used. It's a decent amount to put in the boil but also, again, I think your batch size is...big. If you're not dry hopping and the latest addition is 20 min then I would try a re-build of the hop profile depending on what you want. You'll get some flavor from the 20 min addition but nothing super punchy. I don't know what you're looking for exactly, but if you're drinking modern IPAs and wondering why yours doesn't match up then this is why. I feel annoying continuing to say this, but...all the more reason to tighten up on your oxygen protocols if possible. Hops are pretty expensive and if whatever flavor you have is diminishing then it's almost assuredly oxidation eating it up. Without addressing that then adding more hops is likely just going to make you a similar beer at a higher cost for ingredients4oz of chinook 1hr

4oz of cascade 20min

I see absolutely no problems here. Carry on... At least they're less expensive that whatever new hotness is getting printed on cans tomorrow.Went old school on the hops

Side question for those who are doing pressure transfers using your CO2 tank. What pressure are you transferring beer to your serving keg? Reason I ask is that I recently brewed a hoppy pale ale and fermented in a keg, where the blowoff smelled wonderful, but the final product tasted underwhelming. I pressure transferred it to a dry-hop keg for a couple days, and then pressure transferred to a serving keg, with a blowoff attached to the gas in port. I wasn't really watching what psi I transferred, but I'm guessing around 10psi. Is that too high and could it cause a lot of the aromatics and hop flavor to blow off?

I can give hop types and quantities when I get home and can check Beersmith.

I can give hop types and quantities when I get home and can check Beersmith.

DuncB

Well-Known Member

I try and get my fermenting keg / fermentasaurus at the serving vols pressure.

I get the purged ( with ferment gas in my case) receiving keg at the same pressure as the fermenter during the purge phase.

This means the receiving keg is going to be at a higher pressure than the fermenting keg after cold crash.

When doing closed transfer the excess gas equalises with the ferment keg and then it stays balanced throughout the closed transfer, because it's a balanced siphon of liquid out and liquid in with gas displacing to keep it all going.

But regarding the aroma that is volatilised hop aroma in the headspace. It will always try and stay in balance some in liquid and some in gas.

Therefore if you double the headspace then more volatiles will come out of the beer to form equilibrium.

This may well be why aroma decays as the keg is drunk, perhaps " bag " served beers in disposable kegs such as key kegs hang onto their aroma and hence flavour for longer. I can't test this theory but seems possible.

I get the purged ( with ferment gas in my case) receiving keg at the same pressure as the fermenter during the purge phase.

This means the receiving keg is going to be at a higher pressure than the fermenting keg after cold crash.

When doing closed transfer the excess gas equalises with the ferment keg and then it stays balanced throughout the closed transfer, because it's a balanced siphon of liquid out and liquid in with gas displacing to keep it all going.

But regarding the aroma that is volatilised hop aroma in the headspace. It will always try and stay in balance some in liquid and some in gas.

Therefore if you double the headspace then more volatiles will come out of the beer to form equilibrium.

This may well be why aroma decays as the keg is drunk, perhaps " bag " served beers in disposable kegs such as key kegs hang onto their aroma and hence flavour for longer. I can't test this theory but seems possible.

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

If you're pushing into a keg and you've got a blowoff or you're pulling the PRV then you're going to lose a bunch of aromatics. No way around it. I've been stuck in a crap situation a couple time doing that for IPAs. They always seem a little more muted to me. They are still tasty and I don't lose more hop flavor over time than I would expect, but the starting point seems lower for sure. Aroma walks hand in hand with flavor.

If everything works out and my sending vessel can take the pressure I just make sure the pressure is low on the receiving vessel and push slow with just enough PSI to get the job done. Honestly, not something I've done all that much, though.

If everything works out and my sending vessel can take the pressure I just make sure the pressure is low on the receiving vessel and push slow with just enough PSI to get the job done. Honestly, not something I've done all that much, though.

Transfer pressure is mostly going to affect the flow rate. You aren't flowing excess CO2 thru the beer during transfer, no matter what pressure you use, so I don't think transfer pressure will have any type of "sweep out the hop flavor" effect. If you blew excess CO2 thru the system after liquid transfer was complete, that might be a different story.Side question for those who are doing pressure transfers using your CO2 tank. What pressure are you transferring beer to your serving keg? Reason I ask is that I recently brewed a hoppy pale ale and fermented in a keg, where the blowoff smelled wonderful, but the final product tasted underwhelming. I pressure transferred it to a dry-hop keg for a couple days, and then pressure transferred to a serving keg, with a blowoff attached to the gas in port. I wasn't really watching what psi I transferred, but I'm guessing around 10psi. Is that too high and could it cause a lot of the aromatics and hop flavor to blow off?

I can give hop types and quantities when I get home and can check Beersmith.

Brew on

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

Totally agreed! If he's popping the top on the receiving keg he's still pushing out some of those volatile aromatics, though, right? Maybe I'm missing something, though. I'm reading it that he's pushing into the liquid port of the receiving keg and leaving the gas port of the same keg open with a blowoff...Transfer pressure is mostly going to affect the flow rate. You aren't flowing excess CO2 thru the beer during transfer, no matter what pressure you use, so I don't think transfer pressure will have any type of "sweep out the hop flavor" effect.

Yes. Gas port of the receiving keg with a blowoff from the gas QD and into a container of StarSan.Totally agreed! If he's popping the top on the receiving keg he's still pushing out some of those volatile aromatics, though, right? Maybe I'm missing something, though. I'm reading it that he's pushing into the liquid port of the receiving keg and leaving the gas port of the same keg open with a blowoff...

Yes, you will lose whatever hop volatiles are in the receiving keg headspace. But that is going to happen no matter what you do.Totally agreed! If he's popping the top on the receiving keg he's still pushing out some of those volatile aromatics, though, right? Maybe I'm missing something, though. I'm reading it that he's pushing into the liquid port of the receiving keg and leaving the gas port of the same keg open with a blowoff...

An argument could be made that the hop volatiles don't have time to come to equilibrium between the beer and the headspace during the transfer time, meaning the longer the transfer takes, the more hop volatiles can escape into the headspace, and eventually out the vent. If this is the case, then using higher pressure to transfer faster, would lessen the amount of volatiles lost during transfer.

Brew on

Is this batch dry hopped? One of the changes I made to get more hop character in my IPAs was...surprise...use more hops! For a 5 gallon batch of an American IPA, I am usually using around 9 to 10 oz of hops, with about 5 oz late in the boil or at flameout and another 4 oz in a dry hop charge. For a more classic APA or IPA, I like the character from an addition in the 15 to 10 minute range. For a more juicy character, I will move those hops to a hop stand.

My current go to IPA recipe was inspired by some Racer 5 clones that I found, but I have increased the hopping rate a bit.

Looks like I am coming in way short on the hops... the recipes I used to follow 15 years ago would call for 1oz of this and 1oz of that so I thought I was ok. My neighbor is a hop farmer, I will see what he has or get some of the older hops from hopsdirect and pour the coals to it! Also I will reevaluate timing.

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

Hmm, thank you for the response. I hadn't considered that and I realize now I probably haven't thought deeply enough on this topic. I'm going to need to do some more reading and think about my procedures. I appreciate you getting back!An argument could be made that the hop volatiles don't have time to come to equilibrium between the beer and the headspace during the transfer time, meaning the longer the transfer takes, the more hop volatiles can escape into the headspace, and eventually out the vent. If this is the case, then using higher pressure to transfer faster, would lessen the amount of volatiles lost during transfer

Also, that's 29lbs in the grist bill... The breakdown looks right so I'm assuming that's NOT a five gallon batch. Otherwise, you might have just a sliiiight efficiency problemScale the hop amounts mentioned here according to whatever batch size you're doing.

I would roughly agree with the numbers that @CascadesBrewer gave above. I probably push a little more of the hops into the dry hop and a little less in the whirlpool but not by much. I sprinkle maybe an ounce in at 5 and 15 each and then add whatever at 30 to adjust the IBU and add a little more complexity. Probably about 1.5-2oz there. Mix and match for the later additions to maximize the potential from each hop. Google the survivables chart and check that out if you're interested in this. Centennial carries over some great compounds that survive boiling and fermentation and show up in the final beer. Some other hops do too. Some other hops don't. Chinook is not super high on the list and cascade is even lower. I would say push those hops a little later and blend with another hop like Centennial. The 2022 Hop and Brew School presentation gives a really beautiful, clear breakdown of these survivable compounds and what flavors they can bring to your beer.

Even for a five gallon batch I would say that's not very high for overall hops used. It's a decent amount to put in the boil but also, again, I think your batch size is...big. If you're not dry hopping and the latest addition is 20 min then I would try a re-build of the hop profile depending on what you want. You'll get some flavor from the 20 min addition but nothing super punchy. I don't know what you're looking for exactly, but if you're drinking modern IPAs and wondering why yours doesn't match up then this is why. I feel annoying continuing to say this, but...all the more reason to tighten up on your oxygen protocols if possible. Hops are pretty expensive and if whatever flavor you have is diminishing then it's almost assuredly oxidation eating it up. Without addressing that then adding more hops is likely just going to make you a similar beer at a higher cost for ingredients

I see absolutely no problems here. Carry on... At least they're less expensive that whatever new hotness is getting printed on cans tomorrow.

I shoot for 14+ gallon boil with a steam condenser lid and 13 into the conical. I split what I brew with a older friend and almost never buy beer. It seems like I should add way more hops and go for a co2 transfer.

- Joined

- Dec 4, 2021

- Messages

- 408

- Reaction score

- 635

Yeah, I can't say from direct experience but I think it's safe to say it's a whole different IPA world now in comparison to 15 years ago. What you're brewing right now might be totally fine, but just from a very different worldLooks like I am coming in way short on the hops... the recipes I used to follow 15 years ago would call for 1oz of this and 1oz of that so I thought I was ok. My neighbor is a hop farmer, I will see what he has or get some of the older hops from hopsdirect and pour the coals to it! Also I will reevaluate timing.

Good luck with your adventures. Sounds like you're in for some fun!

Similar threads

- Replies

- 5

- Views

- 705

- Replies

- 10

- Views

- 687