Question. My cider has stopped bubbling. It's been about 10 days. 3 of them have cleared up nicely but the 4th (bottom left) is still cloudy. Same exact ingredients went into all. Is there a problem with it? Should it be tossed?

10 days,,,I’d rack to a secondary vessel it will clear up. Looks like you used a beer yeast

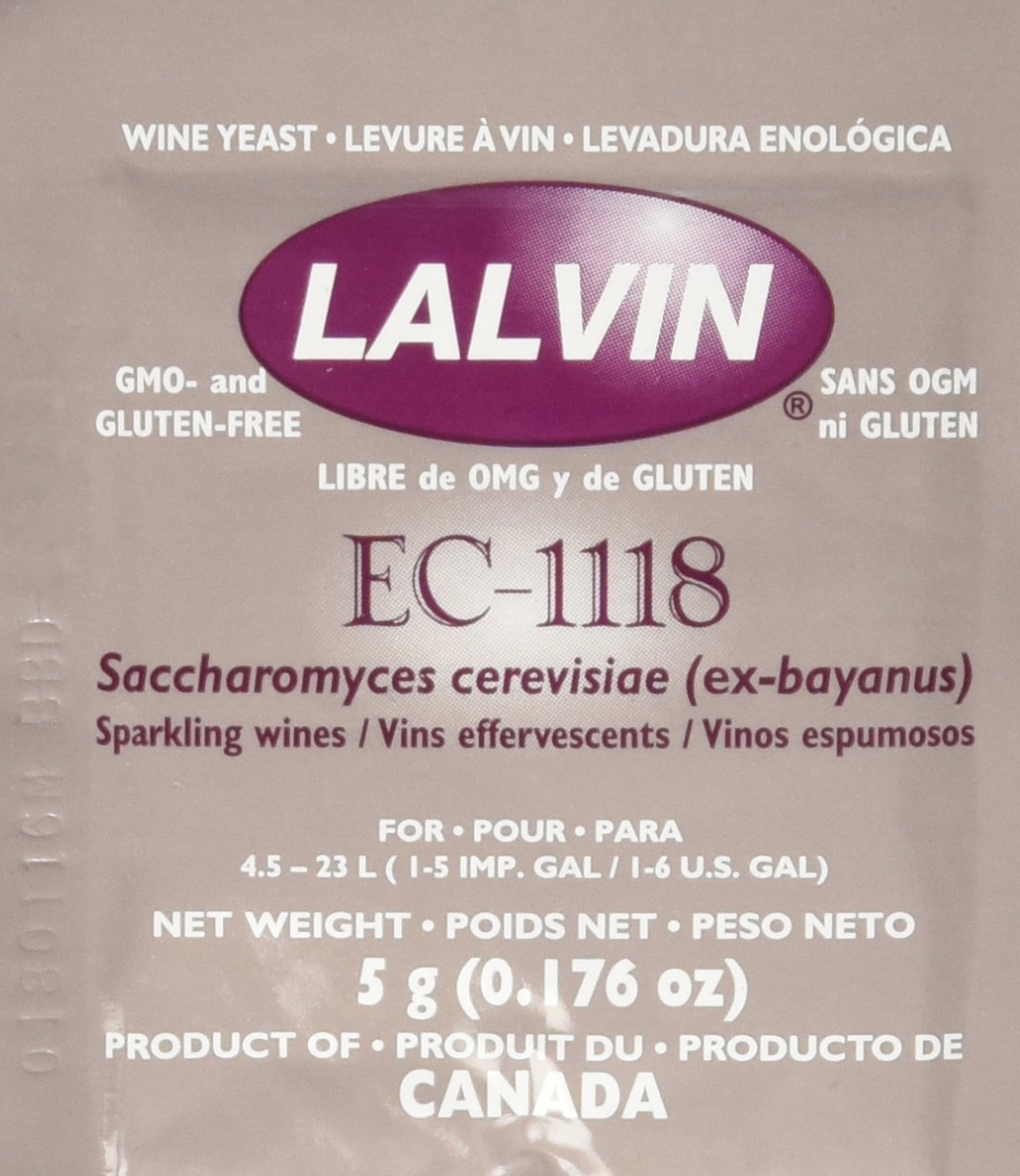

With EC 1118 It should be bone dry. Consider trying Safeale S04 or S05 next time.

Depends on how sweet you want it. But EC 1118 will continue to consume any sugars added up to about 18% alcohol. You either must stabilize / inhibit the yeast with those chemicals that do that, kill them by pasteurizing or filter them out to be able to sweeten your cider. I personally prefer cold crashing and pasteurization. See the "sticky" at the top of the forum from Pappers for pasturizing.

EC-1118 isn't bad, but I'd recommend D47 or Mangrove Jack's M02 for future use, they retained more flavor in my store bought filtered juice yeast tests.I used this. It's what the beardy man told me to use. LOL

View attachment 707276

I seem to be missing something here, cause people keep talking about this or that yeast finishing at a higher FG. I just did a comparison with EC-1118, Safcider, D47, US-05, and Mangrove Jack's M02. Primary only for a month and a half. All finished 0.999-1.001. Past use of S04 also finished here. Is it that I'm doing primary longer than others or some other reason I'm not seeing any significant variation in FG? Store bought filtered juice is what I'm using.With EC 1118 It should be bone dry. Consider trying Safeale S04 or S05 next time.

Way too much space. You want the least possible amount of headspace possible for secondary. 4 gallons in a 5 gallon carboy is fine for primary, as CO2 production will flush out nearly all the O2, but in secondary there's not much CO2 production, if any, so headpsace will lead to oxidation.Also, if the advice is to rack it, I have a 5 gallon container. Can I put 4 gallons into a 5 gallon container or will the remaining air not be good for it?

Then can I just leave it where it is? I have no more containers.Way too much space. You want the least possible amount of headspace possible for secondary. 4 gallons in a 5 gallon carboy is fine for primary, as CO2 production will flush out nearly all the O2, but in secondary there's not much CO2 production, if any, so headpsace will lead to oxidation.

Likely, but my own experience is still quite limited. I've only started with clear store bought juice, and I've done between a month and a month and a half in primary, no secondary. Of the batches I've made so far:Then can I just leave it where it is? I have no more containers.

Ugh, now I feel super dejected. The instructions call for a can of frozen apple juice concentrate per gallon as a backsweetener. Would it be ok to add 2 per gallon you think?

Yeah, the instructions say to backsweeten then pasturize as soon as I add the concentrate.

Also, if the advice is to rack it, I have a 5 gallon container. Can I put 4 gallons into a 5 gallon container or will the remaining air not be good for it?

I bought it at the blob that ate the world.Rick where do you get your malic acid?

Enter your email address to join: