You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BruControl: Brewery control & automation software

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hi all,

FYI I just posted v1.0 build 28081, which fixes a small bug in numeric entry fields, including the calibration. This bug was created when we fixed the international numeric standard (known as regions or locales) in the last build. Thank you to a user for pointing this out! Download HERE.

We are working on v1.1... stay tuned!

FYI I just posted v1.0 build 28081, which fixes a small bug in numeric entry fields, including the calibration. This bug was created when we fixed the international numeric standard (known as regions or locales) in the last build. Thank you to a user for pointing this out! Download HERE.

We are working on v1.1... stay tuned!

Also, I just added some Element sample images. I always suggest someone uses their own to make your system unique and creative, but feel free to use these as you like! See here for download.

Hey BrunDog, your solution looks great and I hope to implement by the end of summer. I've been researching hardware and sourcing everything and had a question on ethernet shields, is there a big difference in the 5100 vs the 5500 and any reason to use one over the other?

Hi @rmajor55,

Practically speaking, the real difference is a few bucks. The 5500 supports 3.3V interfaces, so if you ever upgrade to something other than the MEGA, you would be covered. It's a newer chipset, so maybe it has some better reliability etc. but I haven't experienced such. So, I guess it comes down to price/preference. Sorry that's not too detailed of an answer!

Practically speaking, the real difference is a few bucks. The 5500 supports 3.3V interfaces, so if you ever upgrade to something other than the MEGA, you would be covered. It's a newer chipset, so maybe it has some better reliability etc. but I haven't experienced such. So, I guess it comes down to price/preference. Sorry that's not too detailed of an answer!

It's detailed enough, the 5100's seem easier to come by as well as a few bucks cheaper so I think I'll go with one of those. Thanks.

There's a new horse in the stable...

View attachment ImageUploadedByHome Brew1502417926.243976.jpg

Wi-Fi, Bluetooth, fast processor, good I/O, built-in buzzer, onboard Li-Po battery support, etc. will make for a great option, especially for fermentation controllers. Firmware in the works!

View attachment ImageUploadedByHome Brew1502417926.243976.jpg

Wi-Fi, Bluetooth, fast processor, good I/O, built-in buzzer, onboard Li-Po battery support, etc. will make for a great option, especially for fermentation controllers. Firmware in the works!

thestealth

Active Member

- Joined

- Aug 29, 2015

- Messages

- 39

- Reaction score

- 14

I was just wondering how you wire your element SSRs to the Mega.

Do you just wire the MEGA's output directly to the SSR?

Most element SSRs I find seem to draw more than the recommended 5ma listed on the schematics. Would it be a better idea to have some sort of signal converter to 12V that can supply more than enough current to switch the SSR?

Do you just wire the MEGA's output directly to the SSR?

Most element SSRs I find seem to draw more than the recommended 5ma listed on the schematics. Would it be a better idea to have some sort of signal converter to 12V that can supply more than enough current to switch the SSR?

Hi @thestealth,

Yes, you can wire directly. I have done this multiple times without concern. However, I think your comment is very valid and worth inspection. Many of the SSR's we use are of fair-at-best quality, so may require more current than documented. I would recommend putting an ammeter inline between the SSR and a 5V supply and check the current. If it is less than the max recommend per pin for that microcontroller interface, you can safely wire it directly. If it is more, an interfacing transistor circuit (or MOSFET, etc.) would be needed.

The MEGA has an absolute max output per pin of 40mA, so that's pretty high. However, you can't use a bunch of these together - there are limitations on total current by pin banks. Anyway, if you can stay below 10mA, you should be fine. This issue will be a bigger problem with the new faster micros, which run at 3.3V. The MEGA is a workhorse - beat it up and it keeps on ticking!

Yes, you can wire directly. I have done this multiple times without concern. However, I think your comment is very valid and worth inspection. Many of the SSR's we use are of fair-at-best quality, so may require more current than documented. I would recommend putting an ammeter inline between the SSR and a 5V supply and check the current. If it is less than the max recommend per pin for that microcontroller interface, you can safely wire it directly. If it is more, an interfacing transistor circuit (or MOSFET, etc.) would be needed.

The MEGA has an absolute max output per pin of 40mA, so that's pretty high. However, you can't use a bunch of these together - there are limitations on total current by pin banks. Anyway, if you can stay below 10mA, you should be fine. This issue will be a bigger problem with the new faster micros, which run at 3.3V. The MEGA is a workhorse - beat it up and it keeps on ticking!

thestealth

Active Member

- Joined

- Aug 29, 2015

- Messages

- 39

- Reaction score

- 14

Hi @thestealth,

Yes, you can wire directly. I have done this multiple times without concern. However, I think your comment is very valid and worth inspection. Many of the SSR's we use are of fair-at-best quality, so may require more current than documented. I would recommend putting an ammeter inline between the SSR and a 5V supply and check the current.

Thanks for the quick advise and sharing your experience. So far I have only used SSRs with a RaspberryPI and some transistor circuits. Knowing the Mega can do 40ma is good to know and should be fine for firing 2 SSRs.

I'll check the current draw when I start building a panel for BruControl implementation and add extra circuity if needed.

Brundog,

Well it looks like I ordered the wrong screw shield, I got the DIN version so I cannot attach an Ethernet shield. I don't feel like sending it back so I guess I will be making connection to the computer via USB. What mini computer were you talking about that was less than $100? All if them I look at seem to be very expensive.

Well it looks like I ordered the wrong screw shield, I got the DIN version so I cannot attach an Ethernet shield. I don't feel like sending it back so I guess I will be making connection to the computer via USB. What mini computer were you talking about that was less than $100? All if them I look at seem to be very expensive.

Hi @shadow160,

Did I give you an incorrect link? If so I will buy it from you so you can get the one you want.

Otherwise, let me take a look and reply back with some links tonight.

Did I give you an incorrect link? If so I will buy it from you so you can get the one you want.

Otherwise, let me take a look and reply back with some links tonight.

I doubt you did, I was ordering products in the middle of the night when my insomnia kicked into high gear....anyway I don't think connecting it to the computer with a USB cord reduces functionality.

In any case Amazon is good with returns IF it really bothered me.

In any case Amazon is good with returns IF it really bothered me.

No, there is no functionality limitation for the USB version.

Anyway, we would want you to have it working the way you want. I also like the idea of having a remote computer running BC all the time (like a server) instead of a dedicated computer. That said, a mini-pc like this should fit the bill: https://www.amazon.com/dp/B01N3RO6X5/?tag=skimlinks_replacement-20

Anyway, we would want you to have it working the way you want. I also like the idea of having a remote computer running BC all the time (like a server) instead of a dedicated computer. That said, a mini-pc like this should fit the bill: https://www.amazon.com/dp/B01N3RO6X5/?tag=skimlinks_replacement-20

Last edited by a moderator:

I have had a lot of success with my brewery controller connected via wifi, but I use a TP-Link wireless bridge. So the MEGA is connected to the bridge via Ethernet and that to the Wifi network. As long as the signal is good it should work ok. Anyway, you have choices. Maybe set it up initially just using a laptop via USB, then decide what to do later.

Edit...

Here is the link to a bridge that will work well per above: https://www.amazon.com/dp/B01CVOLGOG/?tag=skimlinks_replacement-20

This has two Ethernet ports and can act as it's own router if needed. I use an older model and it's worked well on my brewery. I find the latency to be very small - certainly not an issue for brewery operations. Again, the signal needs be solid though.

Edit...

Here is the link to a bridge that will work well per above: https://www.amazon.com/dp/B01CVOLGOG/?tag=skimlinks_replacement-20

This has two Ethernet ports and can act as it's own router if needed. I use an older model and it's worked well on my brewery. I find the latency to be very small - certainly not an issue for brewery operations. Again, the signal needs be solid though.

Last edited by a moderator:

I will keep that in mind, my wifi is good but is heavily used, all of my tv/entertainment streams through it, and my server is Linux. I think I will start with my laptop for a couple of brews then switch over to the mini computer once I bring the keezer and fermentation chamber online with Brucontrol.

So lets go a little further down the rabbit hole here.....is there a way I can use a humidity sensor as a trigger with your system?

So lets go a little further down the rabbit hole here.....is there a way I can use a humidity sensor as a trigger with your system?

Gotcha. The bandwidth used for this control is very low but I hear you that it's busy.

Got a link to said sensor?

Got a link to said sensor?

Maybe something like this. https://www.adafruit.com/product/2857

Something like that could work but would need a custom firmware, or for us to incorporate reading sensors like these permanently due to the I2C communication bus. The LCD display currently uses it so it's not a big step to add.

On the other hand, you can incorporate a sensor like this one natively using the current firmware: https://www.sparkfun.com/products/9569 and calibrate right inside BruControl. Wire the output to an analog input and you are good to go.

On the other hand, you can incorporate a sensor like this one natively using the current firmware: https://www.sparkfun.com/products/9569 and calibrate right inside BruControl. Wire the output to an analog input and you are good to go.

If you aren't dead set on a mini PC, places like Tiger Direct frequently have refurb deals on machines that come with a Win OS installed for $99 or less. No affiliation....

http://m.tigerdirect.com/products/5623152

http://m.tigerdirect.com/products/5623152

augiedoggy

Well-Known Member

If you aren't dead set on a mini PC, places like Tiger Direct frequently have refurb deals on machines that come with a Win OS installed for $99 or less. No affiliation....

http://m.tigerdirect.com/products/5623152

I agree... I bought the very capable window10 pc im typing this on now for $125 refurbed on ebay about 5 years ago...

- Joined

- Mar 24, 2016

- Messages

- 552

- Reaction score

- 60

Would Microsoft Surface Pro be able to run Brewcontroll?

Yes. I haven't tested RT but it may/should work.

Also, FYI BruControl under Parallels/Win10 on a Mac works just fine, as tested by @Gparkins.

Also, FYI BruControl under Parallels/Win10 on a Mac works just fine, as tested by @Gparkins.

RT finally died at least two years ago. I think the MS Surface Pro 2 was the last product that supported RT...

Cheers!

Cheers!

Thanks DT... I knew they switched to real Windows but wasn't sure when.

Yes, of course. Heck, you could use a PWM output to drive a fan and control the speed to match incremental increases in humidity. Automation!!

All that said, if your fan is a ventilation fan, it might just be easier to turn on your fan when you start the boil phase or when your boil reaches a certain temp, because that's when steam starts pretty reliably!

So by incorporating that can I set it to trigger an output for a humidifier or a fan?

Yes, of course. Heck, you could use a PWM output to drive a fan and control the speed to match incremental increases in humidity. Automation!!

All that said, if your fan is a ventilation fan, it might just be easier to turn on your fan when you start the boil phase or when your boil reaches a certain temp, because that's when steam starts pretty reliably!

Thanks DT... I knew they switched to real Windows but wasn't sure when.

Yes, of course. Heck, you could use a PWM output to drive a fan and control the speed to match incremental increases in humidity. Automation!!

All that said, if your fan is a ventilation fan, it might just be easier to turn on your fan when you start the boil phase or when your boil reaches a certain temp, because that's when steam starts pretty reliably!

I have a non brewing application I am looking at this for, think of it as a modified fermentation chamber. I am going to make bacon but with the high temps here in Florida I want to use a temp and humidity controlled environment for dry aging.

Absolutely... Oh man... did you say BACON? This is a project that MUST happen!!

Sensing humidity is easy... how will you control it? Something like this? https://www.amazon.com/dp/B01DC5PPWM/?tag=skimlinks_replacement-20

Sensing humidity is easy... how will you control it? Something like this? https://www.amazon.com/dp/B01DC5PPWM/?tag=skimlinks_replacement-20

Last edited by a moderator:

augiedoggy

Well-Known Member

I actually though about making a high tech smoker/cold smoker with it too... even collected the High temp dc fans to build it so far but my little masterbuilt electric smoker has handled everything Ive thrown at it without issues so im struggling with motivation to finish the project...

this little invention is the best purchase I ever made as far as smoking...https://www.amazon.com/dp/B007ROPJ1...t=&hvlocphy=9005508&hvtargid=pla-309734814916

it smokes for up to 16 hr straight with no maintenance..

Ill be smoking a turkey with it tomorrow.

this little invention is the best purchase I ever made as far as smoking...https://www.amazon.com/dp/B007ROPJ1...t=&hvlocphy=9005508&hvtargid=pla-309734814916

it smokes for up to 16 hr straight with no maintenance..

Ill be smoking a turkey with it tomorrow.

Absolutely... Oh man... did you say BACON? This is a project that MUST happen!!

Sensing humidity is easy... how will you control it? Something like this? https://www.amazon.com/dp/B01DC5PPWM/?tag=skimlinks_replacement-20

I did say bacon I found a black forest maple bacon thread here that started this madness.

Yes that is the plan

Last edited by a moderator:

I actually though about making a high tech smoker/cold smoker with it too... even collected the High temp dc fans to build it so far but my little masterbuilt electric smoker has handled everything Ive thrown at it without issues so im struggling with motivation to finish the project...

this little invention is the best purchase I ever made as far as smoking...https://www.amazon.com/dp/B007ROPJ1...t=&hvlocphy=9005508&hvtargid=pla-309734814916

it smokes for up to 16 hr straight with no maintenance..

Ill be smoking a turkey with it tomorrow.

are you cold smoking the turkey that you are using that smoker on it?

I have that on my amazon list I will be placing an order in the next day or so.

No, there is no functionality limitation for the USB version.

Anyway, we would want you to have it working the way you want. I also like the idea of having a remote computer running BC all the time (like a server) instead of a dedicated computer. That said, a mini-pc like this should fit the bill: https://www.amazon.com/dp/B01N3RO6X5/?tag=skimlinks_replacement-20

Ok to just to keep the options open (aka complicate things) I just figured out that I can pretty easily install a windows on my Linux server with a virtual machine. So I am in the process of installing it now so I can test connectivity from my brewing location. If it is good I might end up switching out the screw shield.

Last edited by a moderator:

augiedoggy

Well-Known Member

are you cold smoking the turkey that you are using that smoker on it?

I have that on my amazon list I will be placing an order in the next day or so.

No I was not cold smoking the turkey... I have a friend that has made bacon with it via cold smoking though.

So this happened... In my fermenting fridge, I have a wine bottle with a stopper & thermowell with the temp probe is down in the thermowell. Currently it has some drinks (sodas, waters) in it while I do not have a beer fermenting. Somebody (aka one of my kids) knocked the bottle over and didn't bother to stand it up the other day. I fixed it and thought nothing of it. Then I noticed this morning the following temp graph, where the fridge was turning on and off every handful of minutes. I thought something was wrong with the software or interface controller or something, but turns out it was reading correctly... the tip of the temp probe had been pulled to the top of the thermowell as a result of the tip over, so it was reading rapid temp changes as a result (i.e. no damping from the bottle and its fluid). Good thing I saw the graph, else the compressor would have been short-cycling for who knows-how long. Moral of the story... it's good to use the graphical data to demonstrate the history and performance!

Sounds like an "Email On Short-Cycle" feature wanting to happen

Cheers!

Cheers!

All kidding aside, this could be done via a script pretty easily! Record the time the output turned off (or on) then the time it turns on again (or off). If that window is short, issue an alarm, which could in turn email you.

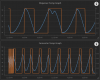

Update on the above... Here is the graph again stretched out to 24 hours. After the probe was fixed, the short cycling slowed, but you can see how fast the compressor is cycling on and off compared to my dispenser. The reason is simple... thermal mass. My dispenser has 5 kegs in it, most of which are 1/2-3/4 full. The fermenter, while set for a higher temp, is nearly empty, so it cools faster and warms up faster. Good learning for anyone looking to stretch the life of their fridge/freezer.... keeping it full will help it cycle less frequently (though it will run for longer periods - not sure if that is a lesser evil). The duty cycle of the fermenter is less than the dispenser, which is probably due to the dispenser being an older freezer and having 5 stainless taps relentlessly pulling heat inside.

FYI the dip in the dispenser temp is the daily defrost cycle kicking on (I never removed the timer relay).

FYI the dip in the dispenser temp is the daily defrost cycle kicking on (I never removed the timer relay).

While I am here I thought I would post up some of the updates we are working on for v1.1, besides any small bugs we have uncovered:

- Web interface

- Timer span --> days

- Timer triggering alarm directly (rather than via a script)

- Element display improvements, dynamic images/guages

- Additional calibrations

- Global variables

- TILT sensor element

- .XML importer (beer.xml or other)

- One-shot function added to digital outputs (thanks @GParkins!)

- Additional script commands

- Enable switch in user control

- Ability to move elements to different workspaces

- Automatic config file backups

- Integrated firmware installation (maybe)

Any others are welcomed. I would also like to thank @crane for helping drive some bug fixes and point out some missing documentation.

- Web interface

- Timer span --> days

- Timer triggering alarm directly (rather than via a script)

- Element display improvements, dynamic images/guages

- Additional calibrations

- Global variables

- TILT sensor element

- .XML importer (beer.xml or other)

- One-shot function added to digital outputs (thanks @GParkins!)

- Additional script commands

- Enable switch in user control

- Ability to move elements to different workspaces

- Automatic config file backups

- Integrated firmware installation (maybe)

Any others are welcomed. I would also like to thank @crane for helping drive some bug fixes and point out some missing documentation.

Similar threads

- Replies

- 29

- Views

- 6K

- Replies

- 51

- Views

- 8K