EmDubeu

Well-Known Member

- Joined

- Feb 21, 2013

- Messages

- 239

- Reaction score

- 46

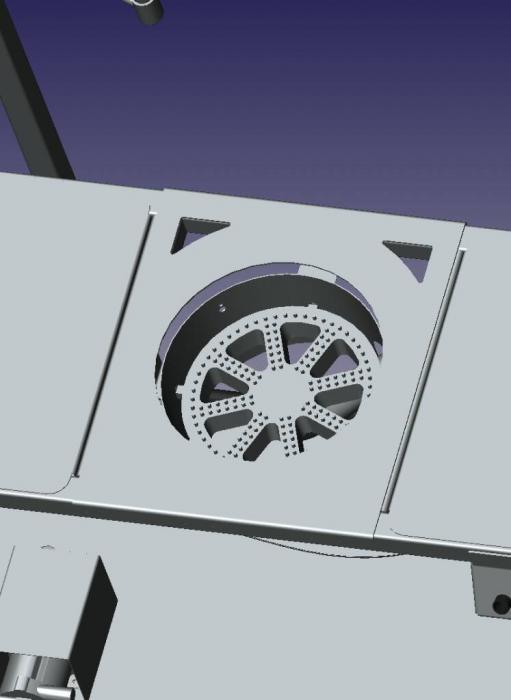

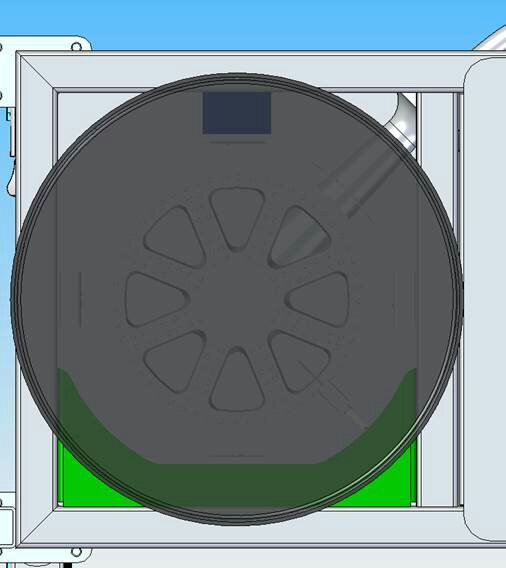

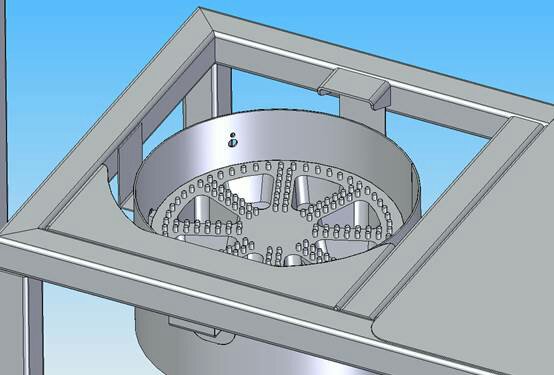

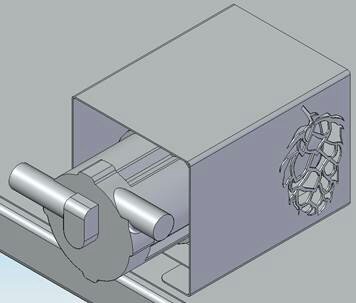

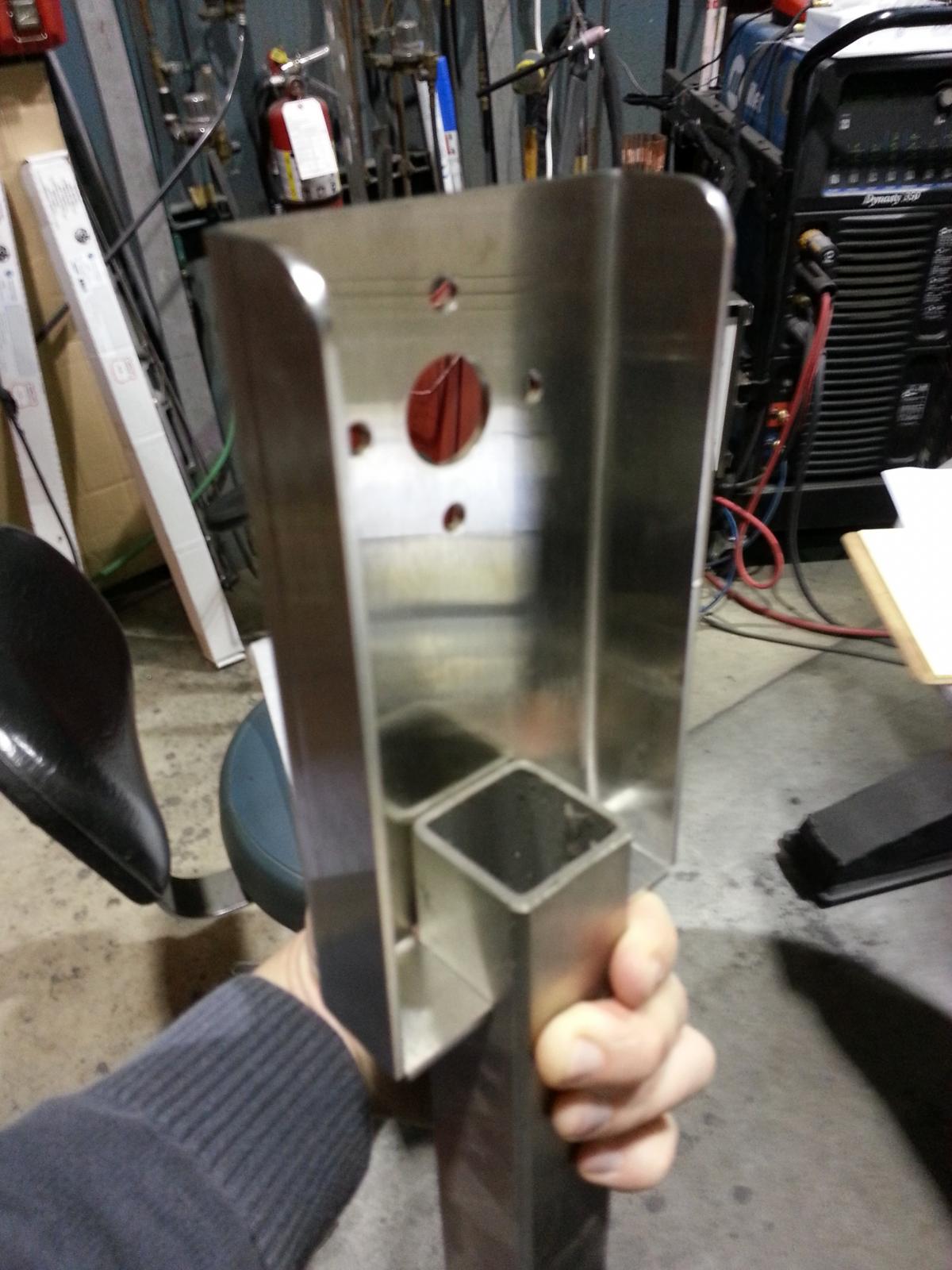

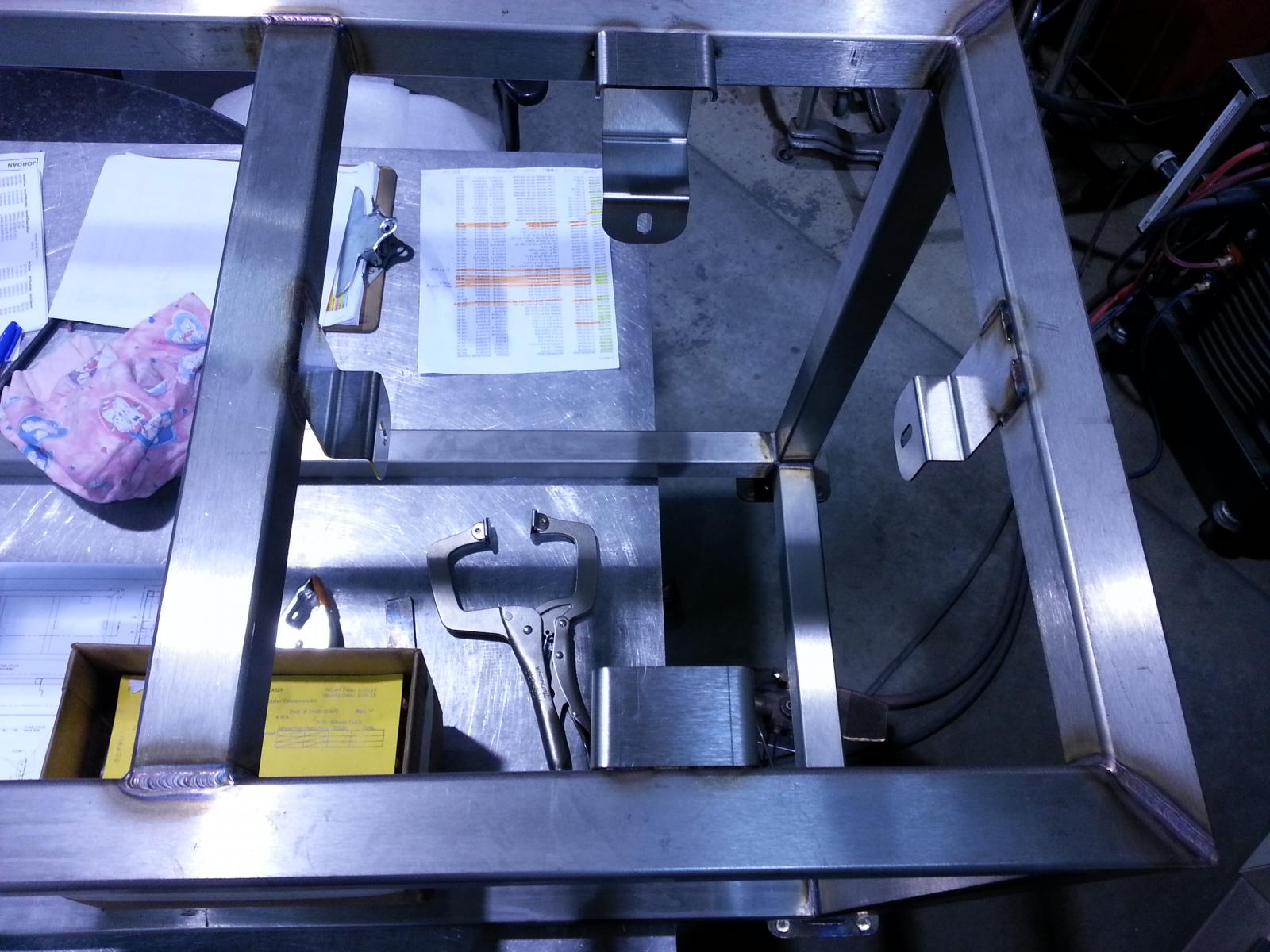

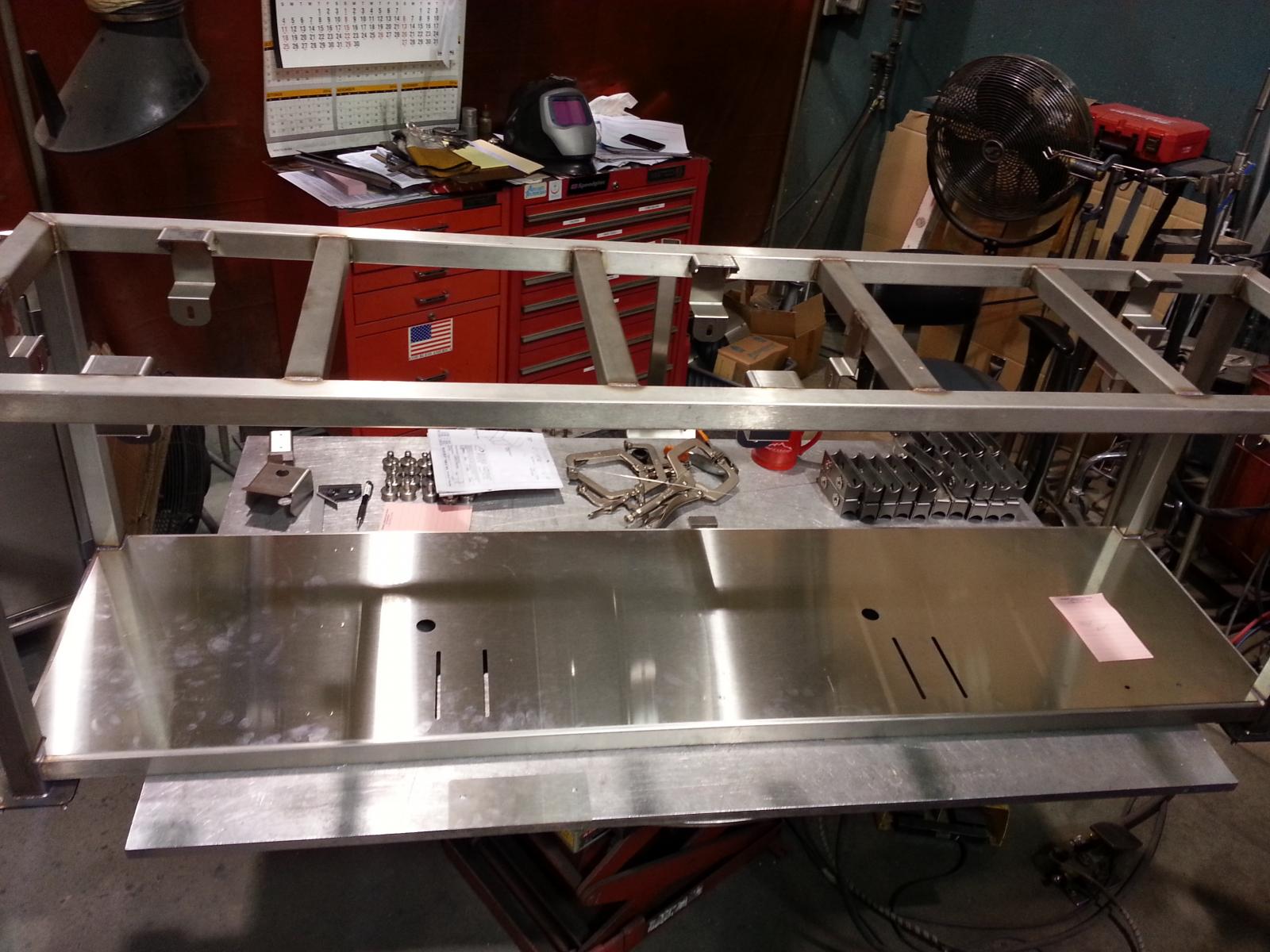

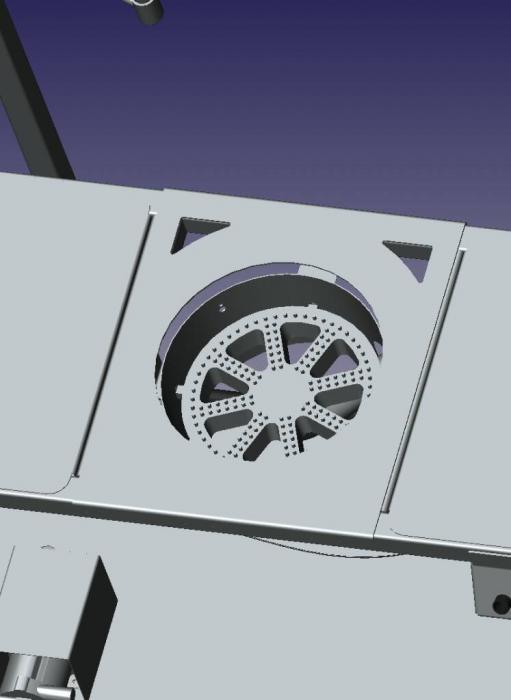

Redesigned the burner cover... Added some vent holes that allow hot gases to vent out the back of the stand, away from any valves on the kettle. We'll see how it goes when we test it in the shop.

Sent from my Nexus 7 using Home Brew mobile app

Sent from my Nexus 7 using Home Brew mobile app