Hamaki

Well-Known Member

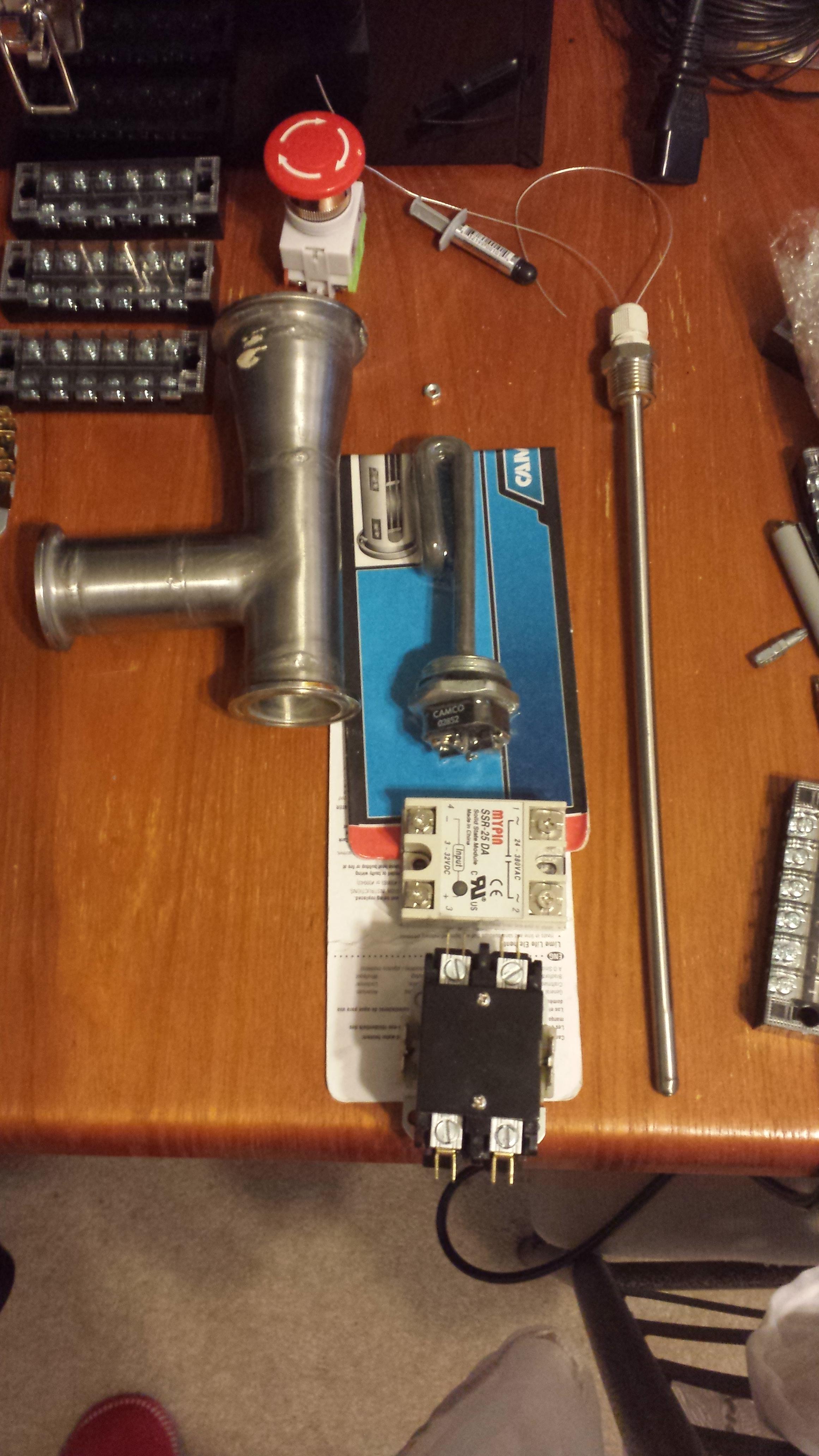

I've looked around a bit but have not found a RIMS tube attached via a 2" TC fitting directly to the outlet of a bottom draining keggle MLT. I think less tubing would mean less heat loss. A light weight 12V pump could connect directly to the RIMS outlet with a relatively short run of discharge tubing back the MLT. Anyone tried this or seen anything similar?