IowaHomeBrewer

Well-Known Member

- Joined

- Jul 26, 2015

- Messages

- 58

- Reaction score

- 12

I'm using a High Gravity BIAB set up, click here to see.

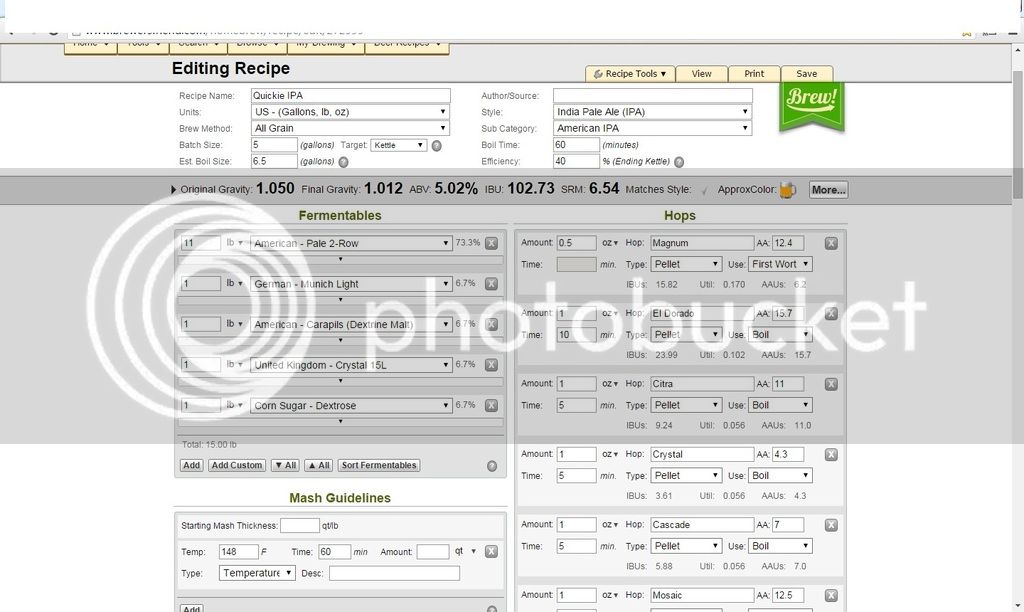

Just today I ran this recipe:

Amount Fermentable PPG °L Bill %

11 lb American - Pale 2-Row 37 1.8 73.3%

1 lb German - Munich Light 37 6 6.7%

1 lb American - Carapils 33 1.8 6.7%

1 lb British Light Crystal 35 10 6.7%

1 lb Corn Sugar - Dextrose 46 0.5 6.7%

I mashed at 148 for 60 minutes. Mashed out at 180 for 10 minutes.

My water volume was 9.3 gallons for the mash/boil.

I did use pH stabilizer to get pH in the right range.

60 minute boil.

I was hoping to get 70% efficiency off of this setup, and was looking for starting gravity of 1.08.

I just finished about an hour ago and took the gravity reading, it was only 1.05 which means only 40% efficiency. I was shooting for an 8% IPA and I'm going to end up with a hop bomb 5% session IPA, which is fine, just not what I was going for.

I knew BIAB was lower efficiency, but not sure what to do to get it better for next time. Here are some things I'm thinking about doing:

1.) Run all the grain through the mill twice.

2.) Change to 90 minute mash

Any other ideas on how to improve efficiency? I suppose I can just beef up the grain bill to account for it, but at 40% I've got to be doing something wrong. Thanks in advance for any suggestions.

Just today I ran this recipe:

Amount Fermentable PPG °L Bill %

11 lb American - Pale 2-Row 37 1.8 73.3%

1 lb German - Munich Light 37 6 6.7%

1 lb American - Carapils 33 1.8 6.7%

1 lb British Light Crystal 35 10 6.7%

1 lb Corn Sugar - Dextrose 46 0.5 6.7%

I mashed at 148 for 60 minutes. Mashed out at 180 for 10 minutes.

My water volume was 9.3 gallons for the mash/boil.

I did use pH stabilizer to get pH in the right range.

60 minute boil.

I was hoping to get 70% efficiency off of this setup, and was looking for starting gravity of 1.08.

I just finished about an hour ago and took the gravity reading, it was only 1.05 which means only 40% efficiency. I was shooting for an 8% IPA and I'm going to end up with a hop bomb 5% session IPA, which is fine, just not what I was going for.

I knew BIAB was lower efficiency, but not sure what to do to get it better for next time. Here are some things I'm thinking about doing:

1.) Run all the grain through the mill twice.

2.) Change to 90 minute mash

Any other ideas on how to improve efficiency? I suppose I can just beef up the grain bill to account for it, but at 40% I've got to be doing something wrong. Thanks in advance for any suggestions.