Hey guys,

Hope someone can help, I'm pulling my hair out trying to make sense of Beersmith. I brew with the Unibrau, and I can NEVER get my mash efficiencies and gravities right. I have spent a couple of hours figuring out the volumes and losses for my setup, they are here:

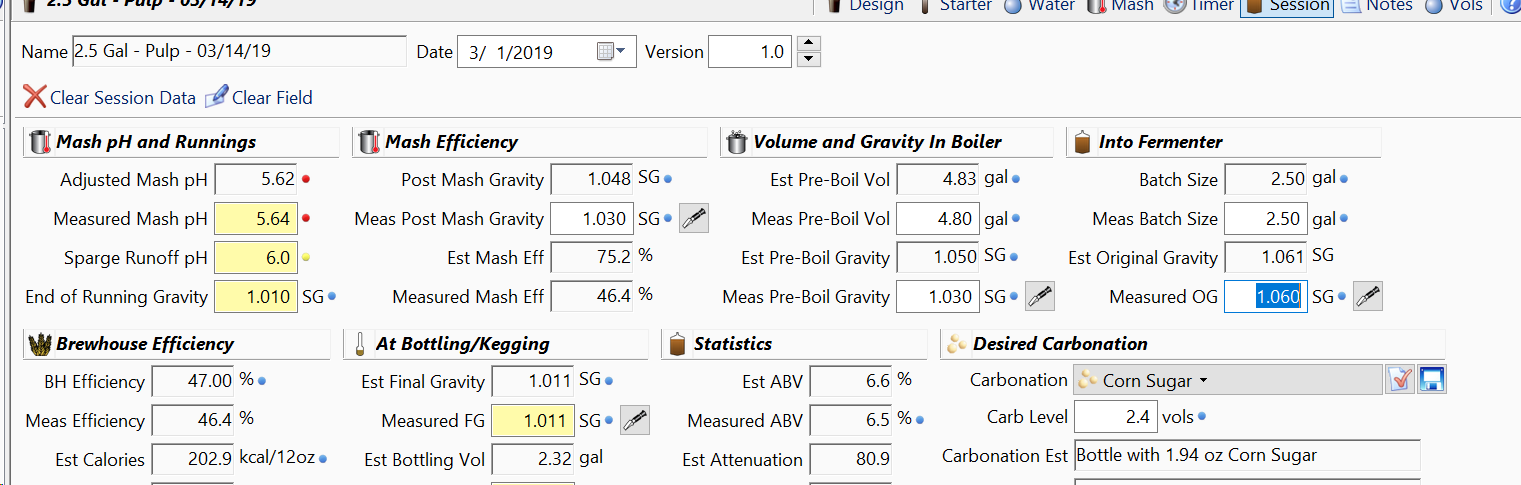

With no diptube, i leave behind about 1.5 gallons of wort. Which isnt awesome, but I have it accounted for. My concern comes with a recent recipe I brewed. I purposely set my Brewhouse efficiency low to try and account for mash efficiency, and here is what I dont understand.

It estimated my mash efficiency at around 75%, but my measured came in at 46%. This isnt the big deal, but what is, was my brewhouse efficiency was almost right in line:

So then lets say my mash efficiency just sucks, but how would I account for that here?

Here is the grain bill as well:

Any help here on what I am doing wrong would help.

Hope someone can help, I'm pulling my hair out trying to make sense of Beersmith. I brew with the Unibrau, and I can NEVER get my mash efficiencies and gravities right. I have spent a couple of hours figuring out the volumes and losses for my setup, they are here:

With no diptube, i leave behind about 1.5 gallons of wort. Which isnt awesome, but I have it accounted for. My concern comes with a recent recipe I brewed. I purposely set my Brewhouse efficiency low to try and account for mash efficiency, and here is what I dont understand.

It estimated my mash efficiency at around 75%, but my measured came in at 46%. This isnt the big deal, but what is, was my brewhouse efficiency was almost right in line:

So then lets say my mash efficiency just sucks, but how would I account for that here?

Here is the grain bill as well:

Any help here on what I am doing wrong would help.