Hey guys. Love you. I'm building a Kal-clone electric brewery, and like any other HERMS system, there are a bunch of ball valves to install in the kettles.

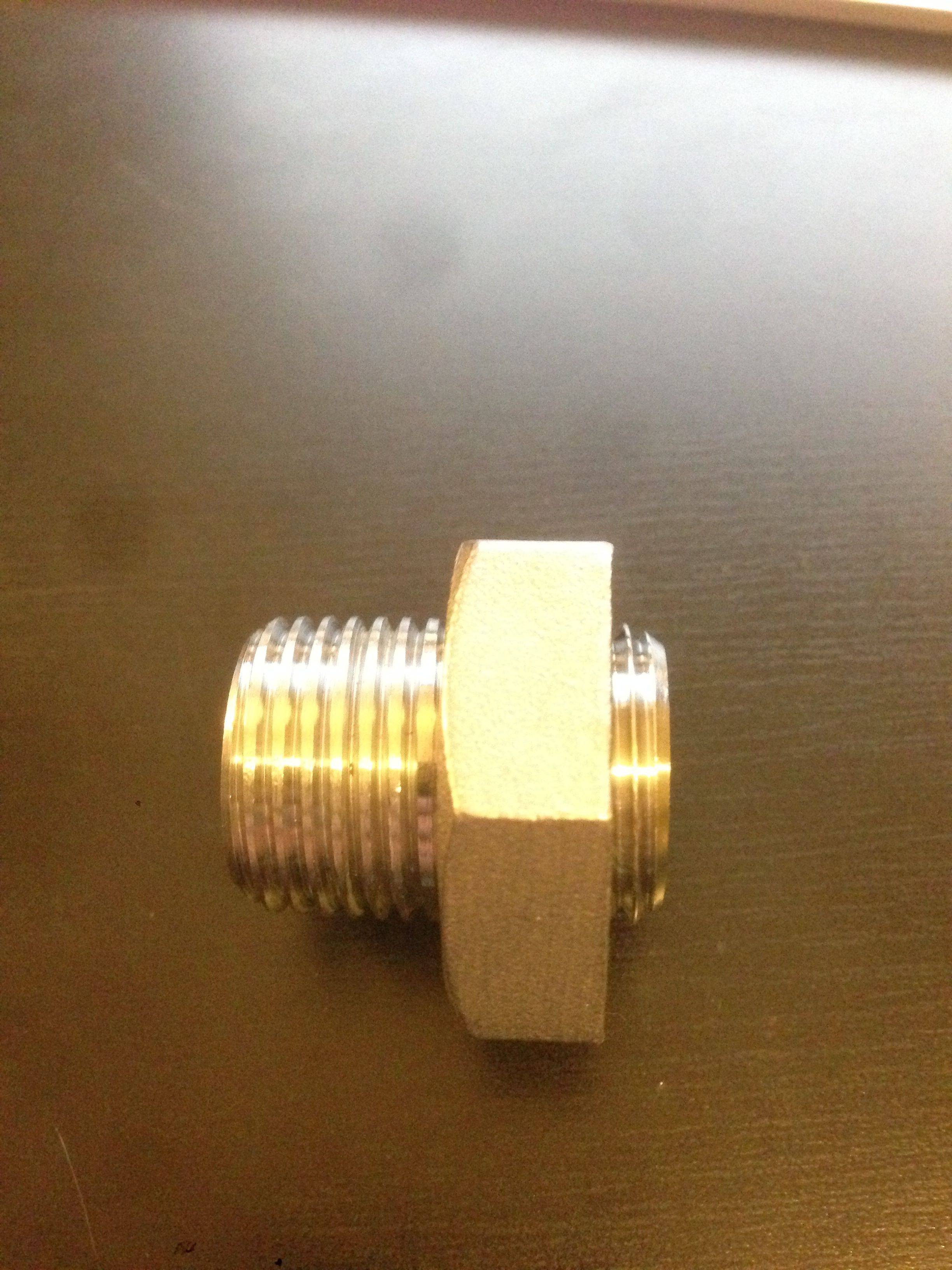

Here's my issue. I got 1/2" close nipples, and I think they may be of sub-par quality. Shouldn't you be able to thread a lock nut all the way from one end of the nipple to the other? mine stops in the middle because the threading is screwed up there (on all of my nipples).

Because of this, I can only screw on the lock nut a tiny bit, so there are maybe 2-3 threads for the ball valve to attach to. I'm not sure any amount of teflon tape can make that connection.

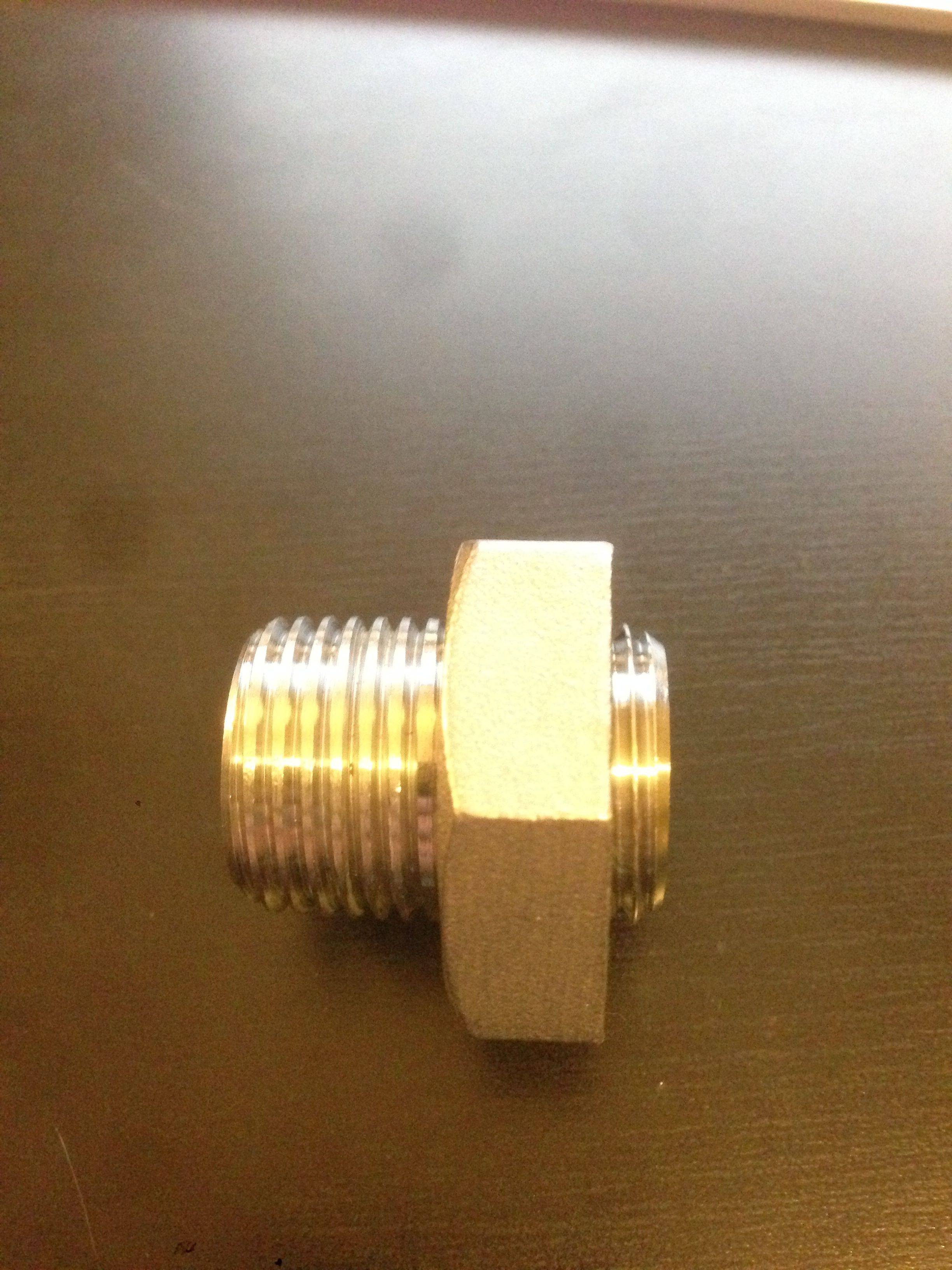

The biggest problem, however, is that there is a gap between the washer on the inside of the kettle and the lock nut / washer / o-ring on the outside of the kettle.

And, yes, i tightened the bejesus out of each end (and i didn't put the o-ring in there for the picture so you could see the gap). The elbow is as far as it can go on the nipple, and so is the lock nut.

Yes, I know that one solution to this problem is to add 15 washers to the inside of the kettle. But is that really necessary? I would very much like to avoid that and install these ball valves properly SO. my questions:

Should you be able to thread a 1/2" lock nut all the way across a 1/2" close nipple?

Do I just need to order better nipples from (for example) morebeer, or are all close nipples' threading messed up in the middle?

Is the ONLY option adding washers to make up the space?

cheers guys , I just feel like an idiot that I can't get this to work

, I just feel like an idiot that I can't get this to work

Here's my issue. I got 1/2" close nipples, and I think they may be of sub-par quality. Shouldn't you be able to thread a lock nut all the way from one end of the nipple to the other? mine stops in the middle because the threading is screwed up there (on all of my nipples).

Because of this, I can only screw on the lock nut a tiny bit, so there are maybe 2-3 threads for the ball valve to attach to. I'm not sure any amount of teflon tape can make that connection.

The biggest problem, however, is that there is a gap between the washer on the inside of the kettle and the lock nut / washer / o-ring on the outside of the kettle.

And, yes, i tightened the bejesus out of each end (and i didn't put the o-ring in there for the picture so you could see the gap). The elbow is as far as it can go on the nipple, and so is the lock nut.

Yes, I know that one solution to this problem is to add 15 washers to the inside of the kettle. But is that really necessary? I would very much like to avoid that and install these ball valves properly SO. my questions:

Should you be able to thread a 1/2" lock nut all the way across a 1/2" close nipple?

Do I just need to order better nipples from (for example) morebeer, or are all close nipples' threading messed up in the middle?

Is the ONLY option adding washers to make up the space?

cheers guys

, I just feel like an idiot that I can't get this to work

, I just feel like an idiot that I can't get this to work