OH-Brew

Member

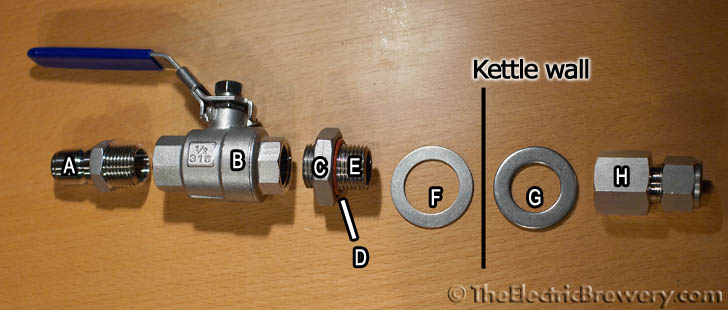

Hello, I'm just wondering if anyone has ever connected their ball valve on the outside of their kettle directly to a compression fitting with 1/2" Male NPT threads on the inside of the kettle? Basically not use the 1/2" nipple that is typically used with weldless fittings. I want to use compression fittings with 1/2" Male NPT threads on one side that compresses a 1/2" O.D. tube (for a dip tube) on the other side.

Everything I have found shows everyone always using the 1/2" NPT nipple (weldless fitting) to connect their ball valve, and then on the inside of the kettle they use something with female NPT threads (i.e. a collar or compression fitting with female threads).

Any thoughts on being able to get away with connecting the ball valve directly to the male threads on a 1/2" NPT compression fitting?

Everything I have found shows everyone always using the 1/2" NPT nipple (weldless fitting) to connect their ball valve, and then on the inside of the kettle they use something with female NPT threads (i.e. a collar or compression fitting with female threads).

Any thoughts on being able to get away with connecting the ball valve directly to the male threads on a 1/2" NPT compression fitting?