Even though I can't really tell how thoroughly the bed is being stirred it's still fascinating.

It appears you were having trouble keeping the grain bed flooded, but I'm not sure how much that matters when the bed is being churned.

The presumptive alternative to bed agitation is wort recirculation, both trying to achieve the same ends.

It's evident the masses go with recirculation - perhaps as it's the simpler to implement - so I'm curious if you had tried that and thought agitation might be a superior approach...

Cheers!

Thanks for the good comments Day Trippr! it is true i mashed a touch dry, i had to install a new false bottom that has almost a gallon and a half dead space at kettle bottom to float the grain bed and provide a flat surface to prevent my agitator from binding.... i just may have forgotten to add that extra bit from the HLT to make up for it....

But doing things like this are always an experiment, i was fully prepared to throw the thing in the garbage after one brew if it wrecked the batch too haha!

I will say on your comment that i DID do recirculated mash first (before a stir arm was even an inkling of a thought), and though it was good, and i did get great efficiency on it... i did find some temperature stratification in the mash tun though. Maybe its just my nature or something but it got me thinking of the easiest way to eliminate that... and voila... a stir arm! and with a recirculated stir mash, i had Zero stratification, and a higher mash efficiency than just recirculation!

I guess the root of the question still remains is the stir arm worth the trouble for the few extra efficiency points and a little less deviation from setpoint in the mash? that may be down to the brewer, My good buddy John uses a simple propane setup banjo burner, and turns out awesome beer!

......but if you do wanna go the extra mile.... a stir arm is a good way to go!

Ill try and put up some of the things i would do to build a better design on the idea in the next little bit, (and next few brews as i run into any issues haha)

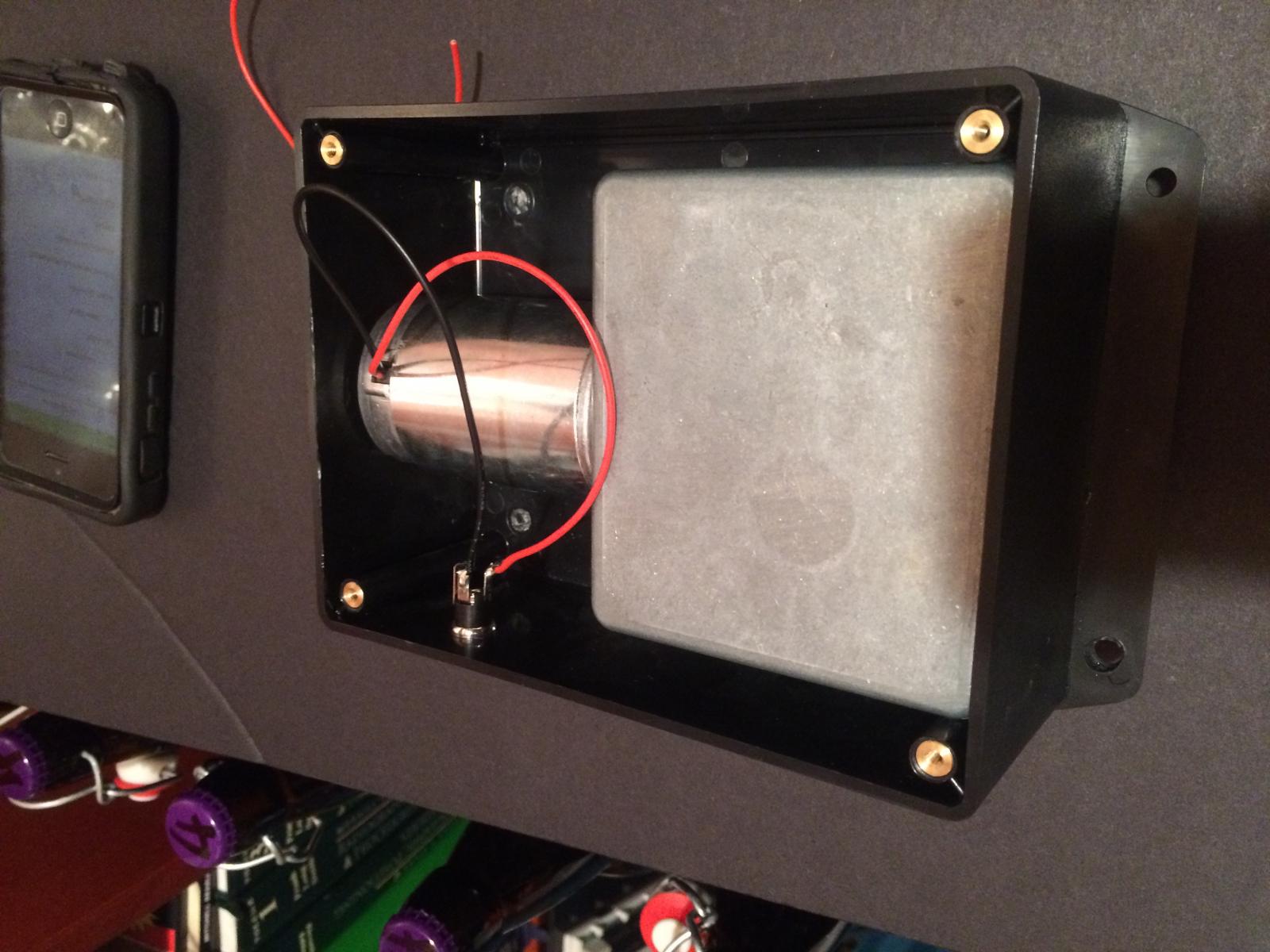

First thing i would do is put a PWM motor speed controller on the motor leads so i can adjust how vigorous the stir is! may not be an important feature, but depending on how thick the mash is it might be a big deal for some people!

Maybe with a few extra Ideas from people in here by the time i build V 2.0 the thing will be pro engineered!