OEHokie

Well-Known Member

Greetings all! I've been reading a lot from this forum lately and have made the decision to try and make an automated rig, but wanted to get some critiques before I continue.

My friends and I brewed our second batch on last sunday and started talking about automation (we're all engineers). We've been doing extract brewing from kits, which simplifies the equipment need.

Problem is, I live in a 700 sq ft apartment, so I'm rather limited in space and electricity. I've noticed that most rigs are gas powered, and if they are electric they use 3-phase power/several kW heating elements... so I did some basic thermo calculations.

For 5 gallon batches where you boil 3 gallons it requires about 3.7 MJ of energy to bring water up to a boil. My apartment's circuit breakers are rated at 15 Amps. I've read that you can use 80% of that safely (12 Amps). On amazon they have some 300 W immersion heaters... I could use 4 of those and still use only 10 Amps (if they're all on) and (ideally) it would bring room temperature water to boil in about an hour. Comparing this to brewing on my electric stovetop this is an improvement. That doesn't factor in heat loss... but I calculated that at boiling temperature. With some insulation around the boiling pot, the loss would be about 40 W, so that's not a huge concern. Before I do anything I'd buy the heaters/insulation and verify that they will boil the water.

Google Spreadsheet for some basic thermo calculations

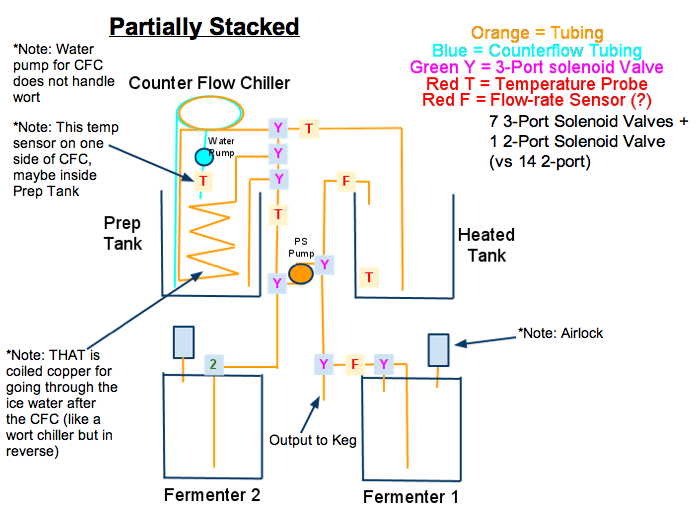

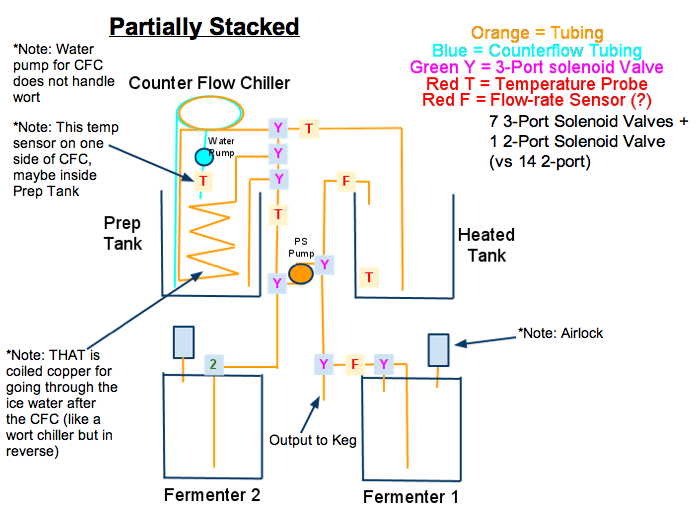

The diagram below is the general flow path. The CFC part would probably get added in later but the "inverted" wort chiller would still be there. The pump is a Peristaltic pump, so that it is easy to clean and nothing mechanical touches the wort itself.

The order of operations would be:

There would also be some kind of setup for automatically steeping/adding ingredients but I haven't figured that out yet (suggestions welcome).

I'm not sure about the solenoid valves and how they will handle everything (never used them before). I've read that they may not work bi-directionally but I dont know if that's a universal problem or just a particular kind. Have people used them bi-directionally? Or is there something else I should use? 3-port vs 2-port?

What tubing should I use? Clear plastic (like in kegerators) or copper?

Does anyone use flow sensors? Recommendations?

For volume sensors I've read about people using float sensors... how do those interface with the arduino or computer?

Can solid state relays vary voltage/power to the heating elements (so it'd be more variable than on/off... though with 4 I'd have 300W steps)There is something to do that, but it's neither efficient or cost effective, is what I gathered from below.

Pump recommendations other than the PS pump?

Once I get a bigger place I'd expand this to do all-grain, upgrade the heaters/pots for bigger batches, and maybe get a conical fermenter to eliminate the secondary fermenter.

Thanks for the recommendations/criticism/advice

Cheers,

My friends and I brewed our second batch on last sunday and started talking about automation (we're all engineers). We've been doing extract brewing from kits, which simplifies the equipment need.

Problem is, I live in a 700 sq ft apartment, so I'm rather limited in space and electricity. I've noticed that most rigs are gas powered, and if they are electric they use 3-phase power/several kW heating elements... so I did some basic thermo calculations.

For 5 gallon batches where you boil 3 gallons it requires about 3.7 MJ of energy to bring water up to a boil. My apartment's circuit breakers are rated at 15 Amps. I've read that you can use 80% of that safely (12 Amps). On amazon they have some 300 W immersion heaters... I could use 4 of those and still use only 10 Amps (if they're all on) and (ideally) it would bring room temperature water to boil in about an hour. Comparing this to brewing on my electric stovetop this is an improvement. That doesn't factor in heat loss... but I calculated that at boiling temperature. With some insulation around the boiling pot, the loss would be about 40 W, so that's not a huge concern. Before I do anything I'd buy the heaters/insulation and verify that they will boil the water.

Google Spreadsheet for some basic thermo calculations

The diagram below is the general flow path. The CFC part would probably get added in later but the "inverted" wort chiller would still be there. The pump is a Peristaltic pump, so that it is easy to clean and nothing mechanical touches the wort itself.

The order of operations would be:

- Load 6 gallons filtered water into prep tank

- Pump 3 gallons into Heated Tank (steep, boil)

- Pump enough water from prep tank into Heated tank to make 5 gallons (would involve a volume sensor of some kind)

- Load Prep tank with ice and cold water

- Pump Heated Tank through chill system (if temp at the output isn't 70degF then recycle into heated tank and repeat) eventually into Fermenter

- After 1 week pump fermenter 1 into fermenter 2

- After 3 weeks bottle/keg and enjoy!

There would also be some kind of setup for automatically steeping/adding ingredients but I haven't figured that out yet (suggestions welcome).

I'm not sure about the solenoid valves and how they will handle everything (never used them before). I've read that they may not work bi-directionally but I dont know if that's a universal problem or just a particular kind. Have people used them bi-directionally? Or is there something else I should use? 3-port vs 2-port?

What tubing should I use? Clear plastic (like in kegerators) or copper?

Does anyone use flow sensors? Recommendations?

For volume sensors I've read about people using float sensors... how do those interface with the arduino or computer?

Can solid state relays vary voltage/power to the heating elements (so it'd be more variable than on/off... though with 4 I'd have 300W steps)There is something to do that, but it's neither efficient or cost effective, is what I gathered from below.

Pump recommendations other than the PS pump?

Once I get a bigger place I'd expand this to do all-grain, upgrade the heaters/pots for bigger batches, and maybe get a conical fermenter to eliminate the secondary fermenter.

Thanks for the recommendations/criticism/advice

Cheers,