Im looking at adding a pump to my all grain system since my back is tired of moving hot wort. Eventually my goal is to go to an electric system but Im going in a phased approach.

Currently I use converted kegs for my MLT and Boil Kettle with no HLT (although I have an extra keg ready Ive never seen the need). I am looking at the chugger steelhead as it seems to be a good overall value.

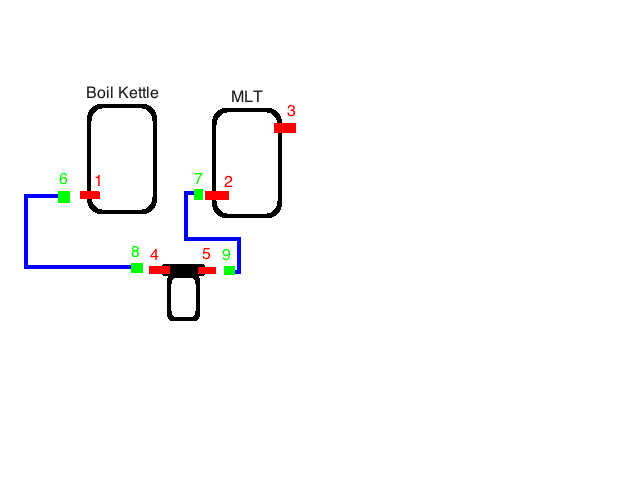

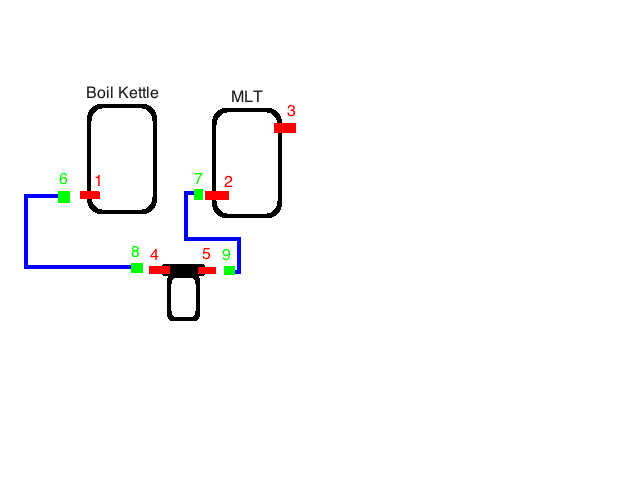

Where Im struggling is with the quick disconnects / design. I have attached my fancy MS paint drawing to show what I think I need and am looking for some input. I would think that quick male disconnects for 1,2,3 and female quick disconnects for 6 and 7.

I would think that quick disconnects for 4,5 and 8,9 would be somewhat optional.

Currently I dont have a valve located in position three so I would have to add that which would enable me to transfer water into my MLT.

I am also struggling with what types of quick disconnects to order I see the traditional style that seems similar to what I use with my air hoses and the cam lock style from Brewers Hardware. Any thoughts on these?

Currently I use converted kegs for my MLT and Boil Kettle with no HLT (although I have an extra keg ready Ive never seen the need). I am looking at the chugger steelhead as it seems to be a good overall value.

Where Im struggling is with the quick disconnects / design. I have attached my fancy MS paint drawing to show what I think I need and am looking for some input. I would think that quick male disconnects for 1,2,3 and female quick disconnects for 6 and 7.

I would think that quick disconnects for 4,5 and 8,9 would be somewhat optional.

Currently I dont have a valve located in position three so I would have to add that which would enable me to transfer water into my MLT.

I am also struggling with what types of quick disconnects to order I see the traditional style that seems similar to what I use with my air hoses and the cam lock style from Brewers Hardware. Any thoughts on these?