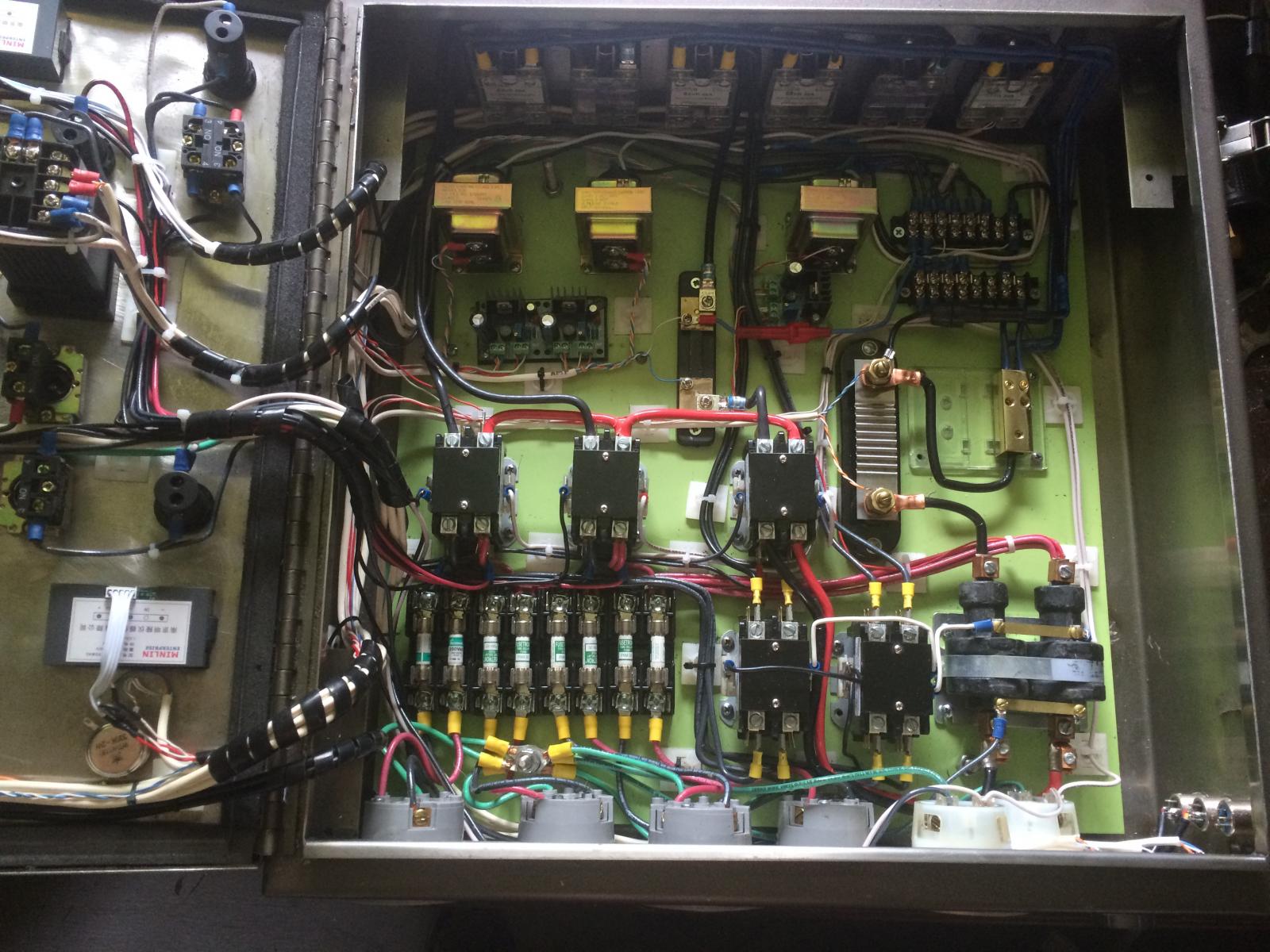

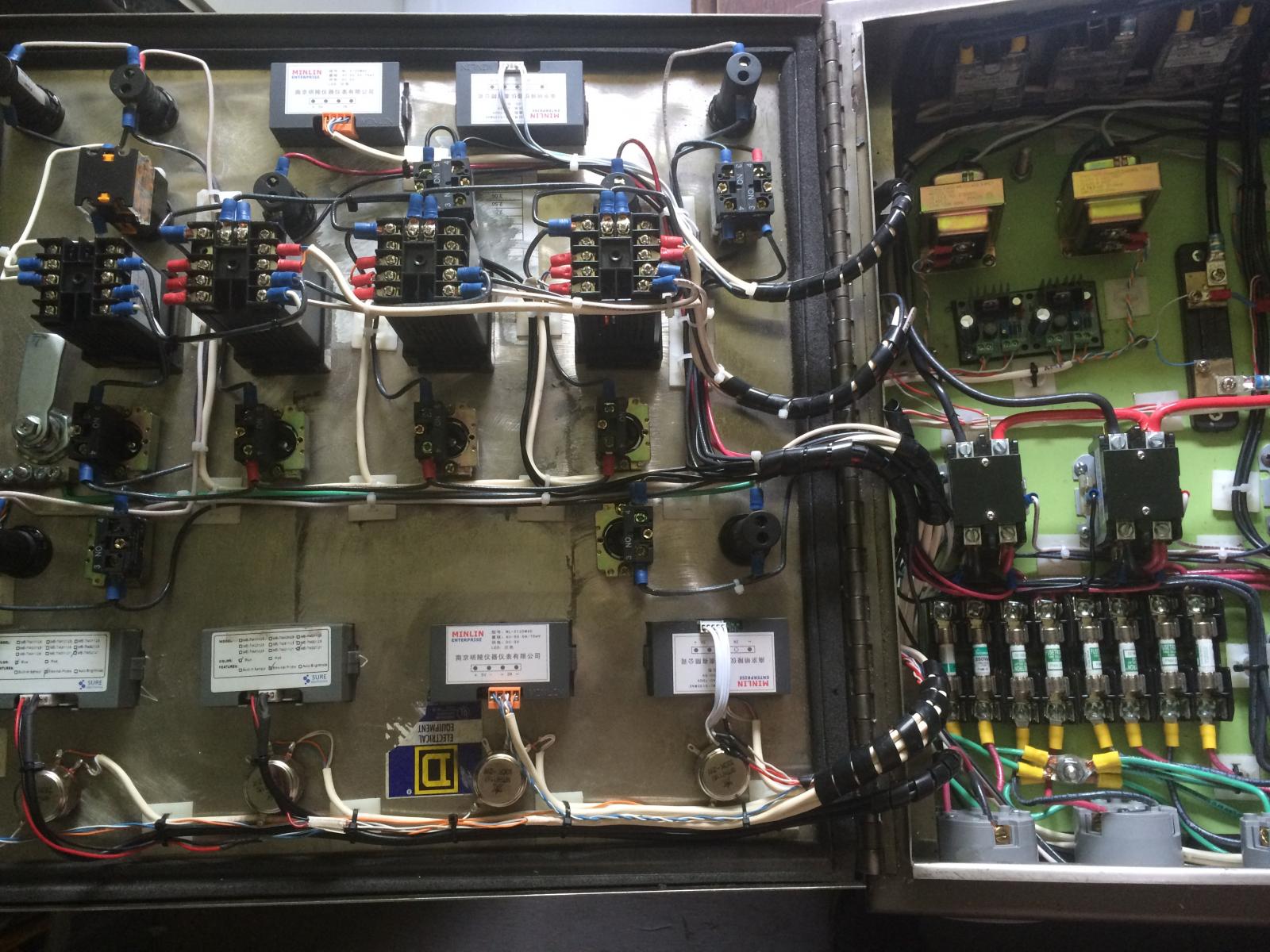

I finally crimped the last wires and set the Pids up. It will be a while before the rest of the rig is done but I can officially call the panel complete. My pics aren't the greatest as the stainless face is a bit camera shy.

View attachment ImageUploadedByHome Brew1437784847.136211.jpgView attachment ImageUploadedByHome Brew1437784866.319575.jpgView attachment ImageUploadedByHome Brew1437784886.470216.jpgView attachment ImageUploadedByHome Brew1437784912.353605.jpgView attachment ImageUploadedByHome Brew1437784931.860986.jpg

View attachment ImageUploadedByHome Brew1437784847.136211.jpgView attachment ImageUploadedByHome Brew1437784866.319575.jpgView attachment ImageUploadedByHome Brew1437784886.470216.jpgView attachment ImageUploadedByHome Brew1437784912.353605.jpgView attachment ImageUploadedByHome Brew1437784931.860986.jpg