You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-in-1 "Boil Kettle, Jacketed Chiller, Conical Fermenter" by Brewha

- Thread starter MeetsCriteria

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

That is one reason I went with the top port route. It allows me to recirc from the racking port through the top and the trub will settle in the bottom and can be dropped out. Another option is a hop filter such as this:

https://www.brewershardware.com/FILTER1-Testing.html

b1v1r (and others who have done this)

Can you please post a pic of how you have your whirlpool hardware setup on your BIAC. Do you have it running through the lid port, or is it attached some other way? I would like to get hardware to do whirlpooling for flameout, 170F cooling hopstand, and to make chilling faster to 68F. Thanks.

wholegraineggos

Member

- Joined

- Jul 7, 2016

- Messages

- 9

- Reaction score

- 0

I'm on the verge of ordering a medium 3-in-1 based on the comments here, but I have some questions first. Apologies if these have already been covered, I searched the thread and didn't find anything.

1. Has anyone used an alternative temperature controller? I've got a spare ITC-1000 which I'd like to use. I haven't found any reason why this wouldn't work, since it seems it's only controlling a relay inside the 240V power box. Any thoughts?

2. Whatever temperature controller you use, the heating element is controlled via hysteresis, correct? Does this make any appreciable difference compared to PID control, assuming the mash is continually recirculated?

3. Is the wedge wire mash colander a worthy upgrade?

Thanks in advance.

1. Has anyone used an alternative temperature controller? I've got a spare ITC-1000 which I'd like to use. I haven't found any reason why this wouldn't work, since it seems it's only controlling a relay inside the 240V power box. Any thoughts?

2. Whatever temperature controller you use, the heating element is controlled via hysteresis, correct? Does this make any appreciable difference compared to PID control, assuming the mash is continually recirculated?

3. Is the wedge wire mash colander a worthy upgrade?

Thanks in advance.

I can't comment on the first two, but as far as the wire colander personally I would see it as worth the upgrade.

I usually get 65-70% and have messed with crush setting, flow recirc, and rice hulls and haven't quite hit the sweet spot of efficiency yet. Occasionally I will get a very slow draining mash and it makes for a long brew day when it takes forever to drain. It would also be nice to recirc a bit faster than I currently do. I just got a hose float so I'll try that out on my next brew and see how it does.

Having said that I don't have the experience of using the wire, but as I understand it, it is less likely to clog/flows better, etc.

I usually get 65-70% and have messed with crush setting, flow recirc, and rice hulls and haven't quite hit the sweet spot of efficiency yet. Occasionally I will get a very slow draining mash and it makes for a long brew day when it takes forever to drain. It would also be nice to recirc a bit faster than I currently do. I just got a hose float so I'll try that out on my next brew and see how it does.

Having said that I don't have the experience of using the wire, but as I understand it, it is less likely to clog/flows better, etc.

JB_Brewing2

Well-Known Member

I'm on the verge of ordering a medium 3-in-1 based on the comments here, but I have some questions first. Apologies if these have already been covered, I searched the thread and didn't find anything.

1. Has anyone used an alternative temperature controller? I've got a spare ITC-1000 which I'd like to use. I haven't found any reason why this wouldn't work, since it seems it's only controlling a relay inside the 240V power box. Any thoughts?

Haven't used anything other than the Auberins unit with which my medium BIAC was originally supplied. I have an ITC-1000 hooked up to a freezer for fermentation control but Idon't know if it would work otherwise. Maybe some one with more electrical knowledge could assist on that questions.

2. Whatever temperature controller you use, the heating element is controlled via hysteresis, correct? Does this make any appreciable difference compared to PID control, assuming the mash is continually recirculated?

Correct, hysteresis is the controlling method. I haven't experienced any significant overshooting or undershooting using the Auberins controller although I'm sure some does occur, just not significant for me.

3. Is the wedge wire mash colander a worthy upgrade?

Unlike some have reported, I have had no issues with the standard colander. I'm careful with my crush and have yet to have a stuck sparge.

Thanks in advance.

I've had no regrets with the system and as I have said in the past, my brews are significantly improved.

wholegraineggos

Member

- Joined

- Jul 7, 2016

- Messages

- 9

- Reaction score

- 0

How about this, if you're using their temperature controller, do you have any issues keeping the mash temperature constant? Appreciate the comments on the mash colander, btw.I can't comment on the first two ...

Thanks.I've had no regrets with the system and as I have said in the past, my brews are significantly improved.

I'm sorely tempted to build my own temperature controller box with a BCS-460 or something. That way I'd get PID control of the heating element, and also be able to control the chiller valves and pumps all with the same unit, plus get temperature logging... but then the whole point of this system is its simplicity. Decisions, decisions.

Thanks for the comments.

I was tempted to use my old controller and a couple other parts to save a few bucks and Nathan said it would be fine. In the end I just went with everything new from Nathan at Brewha and it works great. Yes the efficiency is lower than my old system but I am dialing the recipes to compensate. I appreciate all the saved labor and lifting over my old system which will allow me to keep brewing during my senior years.

How about this, if you're using their temperature controller, do you have any issues keeping the mash temperature constant? Appreciate the comments on the mash colander, btw.

Thanks.

I have the older Ranco style controller they used to supply with the kits. Absolutely zero issues with it. My first couple brews I measured with my Thermapen to get an idea of any difference. As others said, it's negligible. The key when mashing is to find the sweet spot of recirculation and heating element %. A good point to start is 25-30% when you start mashing, this will keep you from overshooting your temp target.

How about this, if you're using their temperature controller, do you have any issues keeping the mash temperature constant?

I have a Brew-Boss controller. It isn't perfect but I appreciate the ability to pre-program the entire brewing session so I don't have to babysit things as much. Unfortunately, it doesn't do fermentation control so after brewing I switch to the Auber ETC that Nathan sells.

wholegraineggos

Member

- Joined

- Jul 7, 2016

- Messages

- 9

- Reaction score

- 0

Thanks for the info, everyone. I've decided to go with a DIY panel for more flexibility with temp control/logging, and easy expansion later on if I decide to add more fermenters (!) Parts actually came out cheaper than the power box + ETC option, so that's a plus.

Now I've got a silly general question for those of you with chiller (glycol or otherwise) setups. Do you leave the chiller pump running all the time, or do you have it turn on when the temp control valve is triggered?

Glad to hear that. This is one of my primary reasons for splurging on this system.I appreciate all the saved labor and lifting over my old system which will allow me to keep brewing during my senior years.

Now I've got a silly general question for those of you with chiller (glycol or otherwise) setups. Do you leave the chiller pump running all the time, or do you have it turn on when the temp control valve is triggered?

Now I've got a silly general question for those of you with chiller (glycol or otherwise) setups. Do you leave the chiller pump running all the time, or do you have it turn on when the temp control valve is triggered?

The chiller provided by Nathan with the BIAC will hold any temperature down to 40F which is the coldest setting available. The chiller is controlled by the temperature controller and holds the desired fermentation temperature within one degree. The chiller only runs when the brew temperature rises and the controller kicks on energizing the chiller. Gotta say that it works great!

The Pliny I'm fermenting now is at 65F and holding steady. I will raise the temperature as fermentation slows. Once it is done fermenting, I will turn the chiller to its lowest setting, 40F, and cold crash the beer for a few days. I will then add gelatin to fine and let it work for a few more days before transferring to kegs to dry hop.

As an aside....When I initially chilled the wort from boiling with tap water, I used hot water to cool the beer so I could whirlpool from 180F and lower. I shut off the water to the jacket at 185F and the wort stabilized at 180F. I whirlpooled in the last 7 ounces of hops, and used a sterilized spoon to stir the wort every 5 minutes for 40 minutes. The temperature slowly dropped to 168F. I turned on the cold water now and chilled to 80F before hooking the BIAC to the chiller to finish cooling to yeast pitching temperature. (I am still trying to determine the best setup to whirlpool with the pump).

Now I've got a silly general question for those of you with chiller (glycol or otherwise) setups. Do you leave the chiller pump running all the time, or do you have it turn on when the temp control valve is triggered?

I use a TK-2000 Aquarium chiller for fermentation and use an EHEIM Compact+ pump to circulate the water from an igloo cooler to the jacket and back. When I'm fermenting I run the pump 24/7.

wholegraineggos

Member

- Joined

- Jul 7, 2016

- Messages

- 9

- Reaction score

- 0

Awesome, so you just split the "cold" power output from the ETC so the chiller and the valve turn on at the same time? Pliny clone sounds good.The chiller provided by Nathan with the BIAC will hold any temperature down to 40F which is the coldest setting available. The chiller is controlled by the temperature controller and holds the desired fermentation temperature within one degree. The chiller only runs when the brew temperature rises and the controller kicks on energizing the chiller. Gotta say that it works great!

I'm considering doing something like this since a glycol chiller is not in the budget right now. Either that or recirculate ice water from an igloo cooler, and top up ice as needed.I use a TK-2000 Aquarium chiller for fermentation and use an EHEIM Compact+ pump to circulate the water from an igloo cooler to the jacket and back. When I'm fermenting I run the pump 24/7.

May I ask, how long has your pump operated like that? I know these pumps can handle restriction on their outlets, but I'd wonder if they could handle that for prolonged periods of time... maybe I'm underestimating how long the temp control valve stays open.

May I ask, how long has your pump operated like that? I know these pumps can handle restriction on their outlets, but I'd wonder if they could handle that for prolonged periods of time... maybe I'm underestimating how long the temp control valve stays open.

If you end up going with a TK series, let me know your plans and I can let you know which one would suit you best. The 500 was around $600 but the 2000 I have now cost just as much as a glycol setup. But, I love having the built-in heater so it's more "all-in-one" than the glycol setup.

Just a quick guess based on about 12 batches and probably 2.5 week average of fermenting the pump has about 700hrs and counting.

Solstice-Brewing

Member

- Joined

- Mar 12, 2015

- Messages

- 14

- Reaction score

- 11

Hi all,

Ive made it to the end of this thread and learned a lot of terrific information about BIAC brewing! Thanks to all for all the helpful hints and confirmation of many of the things Ive been experiencing.

Background:

I got my medium BIAC last summer (2015) and have 15 10 gallon batches through it (batch 15 is fermenting). Im in the mountains of New Mexico, so have garage brewed on 100F and 20F days. The thermal controls that come along with the system are great and the modes Ive learned from this thread - as well as a few of my own - have helped tune this system to make highly drinkable beer. Only one bad batch in the lot when I errantly left the power control on 100% after I heated my strike water that ended up scorching my grains at dough in (shall I say DOH!-in). Lesson learned. Ended up with a smokey weizen bock. If only there was a way to concentrate this valuable alcohol into some other beverage - hmmm.

Mods:

Wort chilling in the summer when my tap water temps are ~80F is a challenge. I run my tap water through an immersion chiller in a 10 gallon cooler (which doubles as my keg cooler for picnics) of iced salt water to lower the temperature of the water going into the water jacket - still takes 45-60 minutes to cool to pitch temps. Im installing a few other fixes (thanks to fathers day gifts from my kids) that will route my boiled wort through a hop rocket and therminator into a racking arm to whirlpool/hopback/filter and chill (all thanks to posts on this thread).

Ferm temp was solved with a couple of mods: I use the temp controller with the heating element on 1-2% for those cold nights - easy. For cooling, I roll my whole medium into an insulated box (2 foam) with an old window AC unit blowing into the "BIAC-erator" with the temp controller the show - heating or cooling. In the arid SW, it can be 100F in the day and in the 50s at night - BIG SWINGS. However, as most have noted, once that big thermal mass is close on temperatures, it just takes some gentle nudging and a good temp controller to keep things on track. With the AC unit, I can get the beer to ~40F in a couple days - even with its near 100F outside (about 90-95 in my insulated, but un-cooled garage). Id love a glycol system, but my kludged up AC system is holding its own for now and was a bit cheaper.

Anyway, enough for this post. Just wanted to say Hi and thanks for all the answers to my unasked questions on efficiencies, cooling, heating, grinding, dumping, hopping, whirling and everything else.

One last thing: Nathan is Awesome - no question!

Kent

Ive made it to the end of this thread and learned a lot of terrific information about BIAC brewing! Thanks to all for all the helpful hints and confirmation of many of the things Ive been experiencing.

Background:

I got my medium BIAC last summer (2015) and have 15 10 gallon batches through it (batch 15 is fermenting). Im in the mountains of New Mexico, so have garage brewed on 100F and 20F days. The thermal controls that come along with the system are great and the modes Ive learned from this thread - as well as a few of my own - have helped tune this system to make highly drinkable beer. Only one bad batch in the lot when I errantly left the power control on 100% after I heated my strike water that ended up scorching my grains at dough in (shall I say DOH!-in). Lesson learned. Ended up with a smokey weizen bock. If only there was a way to concentrate this valuable alcohol into some other beverage - hmmm.

Mods:

Wort chilling in the summer when my tap water temps are ~80F is a challenge. I run my tap water through an immersion chiller in a 10 gallon cooler (which doubles as my keg cooler for picnics) of iced salt water to lower the temperature of the water going into the water jacket - still takes 45-60 minutes to cool to pitch temps. Im installing a few other fixes (thanks to fathers day gifts from my kids) that will route my boiled wort through a hop rocket and therminator into a racking arm to whirlpool/hopback/filter and chill (all thanks to posts on this thread).

Ferm temp was solved with a couple of mods: I use the temp controller with the heating element on 1-2% for those cold nights - easy. For cooling, I roll my whole medium into an insulated box (2 foam) with an old window AC unit blowing into the "BIAC-erator" with the temp controller the show - heating or cooling. In the arid SW, it can be 100F in the day and in the 50s at night - BIG SWINGS. However, as most have noted, once that big thermal mass is close on temperatures, it just takes some gentle nudging and a good temp controller to keep things on track. With the AC unit, I can get the beer to ~40F in a couple days - even with its near 100F outside (about 90-95 in my insulated, but un-cooled garage). Id love a glycol system, but my kludged up AC system is holding its own for now and was a bit cheaper.

Anyway, enough for this post. Just wanted to say Hi and thanks for all the answers to my unasked questions on efficiencies, cooling, heating, grinding, dumping, hopping, whirling and everything else.

One last thing: Nathan is Awesome - no question!

Kent

Now I've got a silly general question for those of you with chiller (glycol or otherwise) setups. Do you leave the chiller pump running all the time, or do you have it turn on when the temp control valve is triggered?

I have the chiller that Nathan sells and don't use the temp control valve at all, preferring to run the pump only when triggered by the ETC.

One thing I really like about the chiller is that it has two stainless steel coils that sit in the reservoir which can be used independently of the main pump. They're designed to be used as an in-line draft cooler but I use one of them to pre-chill my groundwater while wort cooling.

wholegraineggos

Member

- Joined

- Jul 7, 2016

- Messages

- 9

- Reaction score

- 0

Interesting... did you experiment with fermentation heating by applying 1-2% power to the element?If you end up going with a TK series, let me know your plans and I can let you know which one would suit you best. The 500 was around $600 but the 2000 I have now cost just as much as a glycol setup. But, I love having the built-in heater so it's more "all-in-one" than the glycol setup.

That's neat. How long does it take to get the glycol down to chilling temps once the ETC turns it on?I have the chiller that Nathan sells and don't use the temp control valve at all, preferring to run the pump only when triggered by the ETC.

One thing I really like about the chiller is that it has two stainless steel coils that sit in the reservoir which can be used independently of the main pump. They're designed to be used as an in-line draft cooler but I use one of them to pre-chill my groundwater while wort cooling.

The temperature of the liquid in the reservoir(I use water and not glycol) is controlled independently by the chiller and not the ETC so it's always cold. The chiller's pump has its own circuit which is what the ETC switches.

wholegraineggos

Member

- Joined

- Jul 7, 2016

- Messages

- 9

- Reaction score

- 0

Ah, got it. That sounds pretty awesome. Thanks for the info.The temperature of the liquid in the reservoir(I use water and not glycol) is controlled independently by the chiller and not the ETC so it's always cold. The chiller's pump has its own circuit which is what the ETC switches.

Interesting... did you experiment with fermentation heating by applying 1-2% power to the element?

I have the older, analog version of the controller so never tried it. If I was buying one now I would definitely consider that + the glycol for fermentation management.

Jcruse

Well-Known Member

- Joined

- Jan 29, 2015

- Messages

- 61

- Reaction score

- 19

I just placed my order for a medium BIAC with the wedge wire colander, and the order total came out to more than $2500. Nathan emailed me that I would need to provide my SSN for customs purposes (on orders over $2500). Obviously I'm a little hesitant to provide it.

Have any of you had to provide your SSN when ordering your BIAC?

Have any of you had to provide your SSN when ordering your BIAC?

RiverCityBrewer

Well-Known Member

Yep, pretty much everyone had to supply it. If you are worried about it call Nathan, but my transaction was trouble free.

Joe

Joe

Solstice-Brewing

Member

- Joined

- Mar 12, 2015

- Messages

- 14

- Reaction score

- 11

https://help.cbp.gov/app/answers/de...er-/-tax-identification-number-/-irs-number-/

FYI, here's a webpage for Customs and Boarder Protection that answers why this is necessary. Indeed, I was nervous about this as well, but it's required.

cheers,

FYI, here's a webpage for Customs and Boarder Protection that answers why this is necessary. Indeed, I was nervous about this as well, but it's required.

cheers,

JB_Brewing2

Well-Known Member

Can anyone recommend an aquarium chiller for use on the medium BIAC? What size? 1/4hp? Can it be connected directly to the jacket with an aquarium pump supplying the input power to the solenoid valve? Hotter summer than last year and I'm realizing I need a chiller. I apologize as I have no knowledge of how a system like this should work and only wish to use it for fermentation temps.

I would recommend the one from Nathan at Brewha. I'm currently fermenting at 60 degrees Fahrenheit with his chiller and it's about 90 in my garage. It's been over 100 here for more than a week and I could easily lager even with the high ambient temp. I only have the chiller temp at setting 2 (50F) and it goes to 7 (32F)

I have this one http://rapidswholesale.com/3-gal-glycol-unit-1-3-hp-120v.html

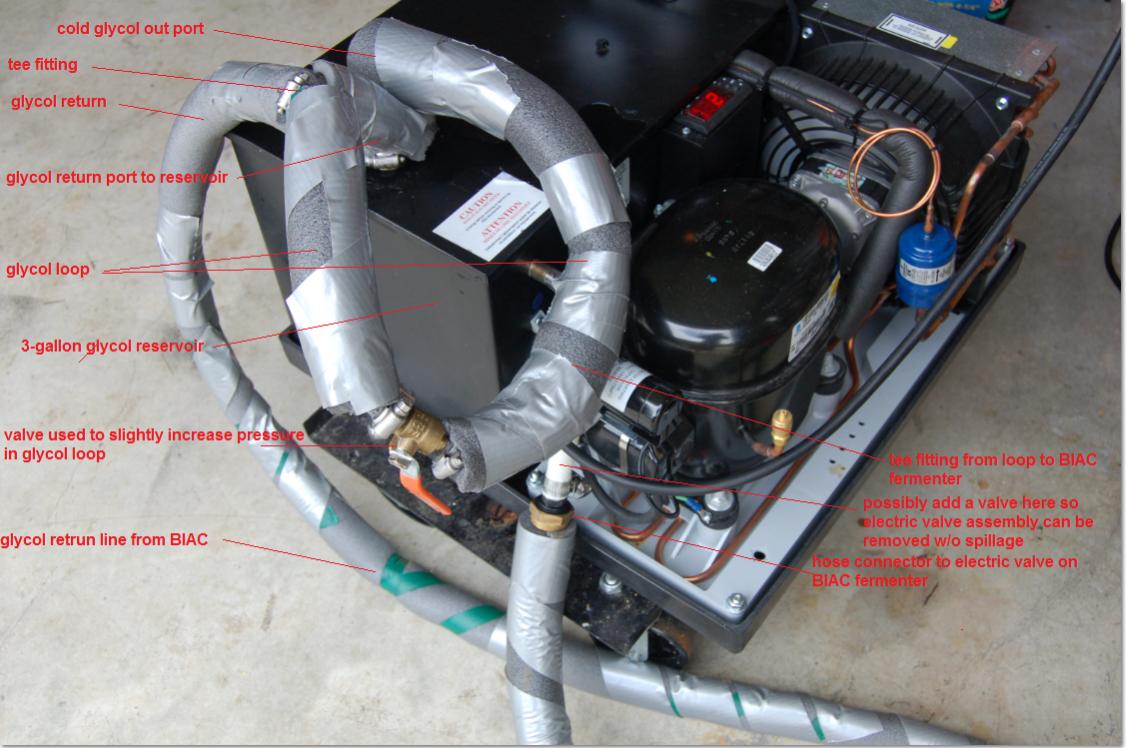

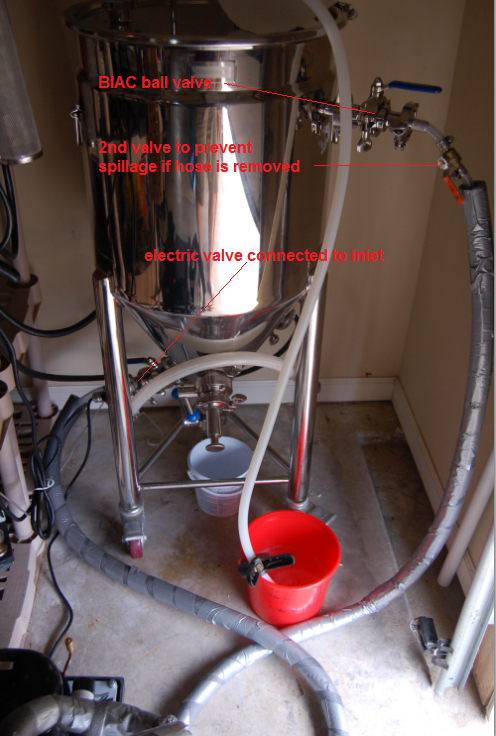

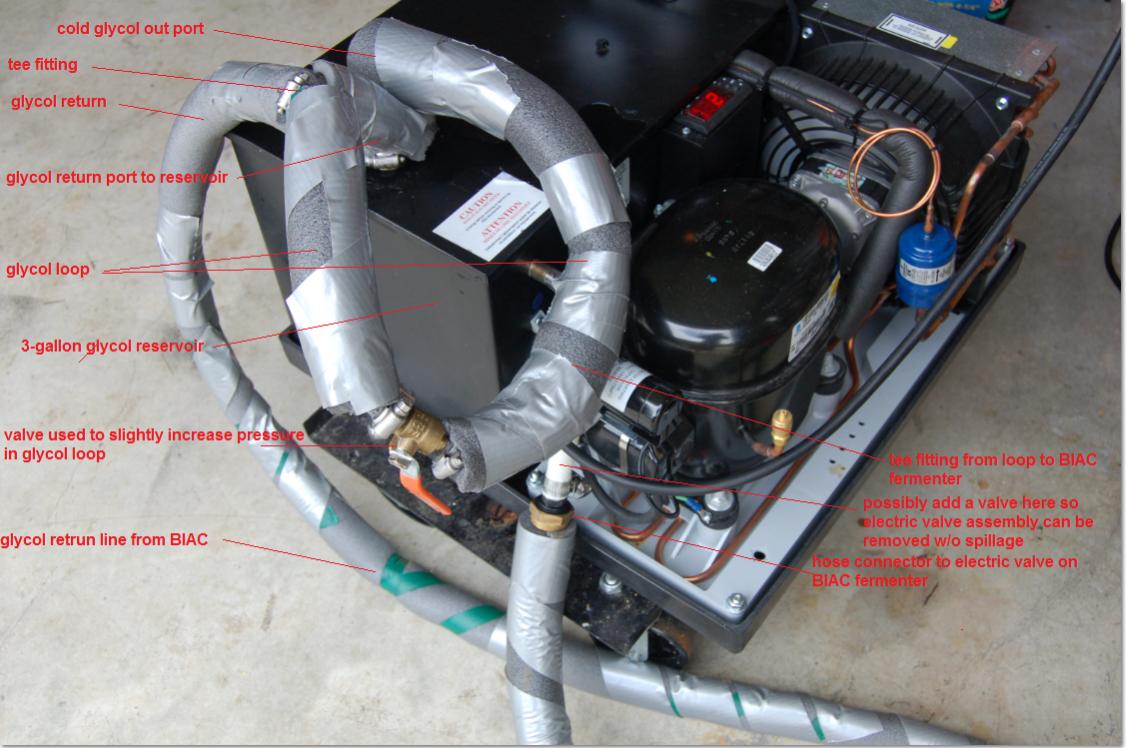

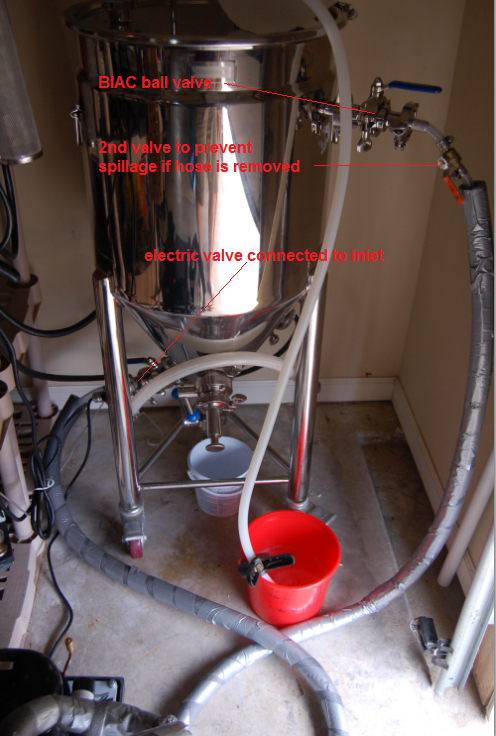

I built a recirculating loop just like a brewery would use so that when not needed in the jacket, the glycol solution just flows back into the chiller reservoir. When the electric valve on the BIAC opens, the glycol takes the path of least resistance and flows through the BIAC. A ball valve slightly closed on the loop creates restriction in the flow thus creating a path of least resistance when the BIAC electric valve opens. I posed a diagram on here somewhere last year.

You will also need a bucket that will fit under your BIAC to catch condensation unless you have the neoprene jacket. I have to empty my 1gal bucket every day in summer.

I built a recirculating loop just like a brewery would use so that when not needed in the jacket, the glycol solution just flows back into the chiller reservoir. When the electric valve on the BIAC opens, the glycol takes the path of least resistance and flows through the BIAC. A ball valve slightly closed on the loop creates restriction in the flow thus creating a path of least resistance when the BIAC electric valve opens. I posed a diagram on here somewhere last year.

You will also need a bucket that will fit under your BIAC to catch condensation unless you have the neoprene jacket. I have to empty my 1gal bucket every day in summer.

I found the schematic and a photo of my chiller. The schematic pdf is at the bottom. I'm using an auto wheel dolly to set my chiller on. It is one of those things that come in sets of two from Harbor Freight or Tractor Supply:

View attachment glycol loop schematic.pdf

View attachment glycol loop schematic.pdf

Fuzzy-felt

Member

If you end up going with a TK series, let me know your plans and I can let you know which one would suit you best. The 500 was around $600 but the 2000 I have now cost just as much as a glycol setup. But, I love having the built-in heater so it's more "all-in-one" than the glycol setup.

cuda6pak,

Would you mind giving me a few pointers on this please? I have a couple of medium BIACs and it would be good to have an 'all-in-one' solution for heating/cooling, in some instances to the two of them in tandem (assuming that I want to run them at the same temperature at the same time). I brew in my shed, where the ambient temperature throughout the year ranges from about 2 - 30°C (36 - 86°F).

Does this bit of kit serve to get down from boil to pitching temperature, or are you more likely to use municipal water to get down to, say, 30°C and then swap over for the final push?

How noisy are these units (I currently have an old shelf chiller that I picked up cheap, but it makes a right old racket)?

Am I likely (when cooling) to need to expel the heat produced to the outside on particularly hot days?

Any help would be appreciated.

JB_Brewing2

Well-Known Member

I found the schematic and a photo of my chiller. The schematic pdf is at the bottom. I'm using an auto wheel dolly to set my chiller on. It is one of those things that come in sets of two from Harbor Freight or Tractor Supply:

Thank you limulus for the schematic and photos. I'm considering the same unit now. If you don't mind I have a few questions regarding the unit and your set up:

1. Do you use a glycol/water mix?

2. Your schematic shows a solenoid valve at the higher output port of the jacket. If that is so, can you tell me why you use a solenoid valve there? (I have a solenoid valve on the input port for the jacket.)

3. I'm confused by the glycol loop. Is this to assist with lessening the loss of glycol when disconnecting the chiller from the BIAC?

4. I didn't see a pressure gauge in the photos. Is this needed to keep the PSI range below 5 based on Nathan's recommendation?

Thank very much for your help on this!!!

cuda6pak,

Would you mind giving me a few pointers on this please? I have a couple of medium BIACs and it would be good to have an 'all-in-one' solution for heating/cooling, in some instances to the two of them in tandem (assuming that I want to run them at the same temperature at the same time). I brew in my shed, where the ambient temperature throughout the year ranges from about 2 - 30°C (36 - 86°F).

Does this bit of kit serve to get down from boil to pitching temperature, or are you more likely to use municipal water to get down to, say, 30°C and then swap over for the final push?

How noisy are these units (I currently have an old shelf chiller that I picked up cheap, but it makes a right old racket)?

Am I likely (when cooling) to need to expel the heat produced to the outside on particularly hot days?

Any help would be appreciated.

I always bring it down to 100F by municipal water before switching over to the TK2000.

The units are fairly quiet, basically just a fan that kicks on along with the compressor when it's in cooling mode. Heat mode it makes no noise. Only noise would be from your pump of choice that is circulating the water.

This depends on what you are doing. If you are simply maintaining fermentation temperature, you will not have a problem. Even with the TK-500 and two medium BIACs in tandum with a regular sized cooler you should not have an issue. The problem with the size of the unit and heat expelling in a small room only becomes an issue when you are trying to cold crash on the hottest parts of the year. Now, if you're not trying to cold crash, but simply maintain fermentation temperature, you would be fine with a TK500 or even TK1000.

If you are planning on cold crashing, I would go with the TK2000 for sure. When it gets to those really hot days that thing will be running full bore to get the beer down to 40F or so, and if all that heat was being expelled into a small shed, I could foresee problems getting down to the temp you want. The garage I used to brew in would get to 90F during the summer, and when cold crashing it would get even hotter in there and struggle a bit.

Another thing you can do to help is insulate the lines coming to/from the TK and cooler, as well as a neoprene jacket that Nathan sells.

Now, having said all that, with the new digital power box Nathan sells as well as the Glycol unit which is around $1k or the same price as a TK2000, I'd be hard pressed not to go with the glycol unit and put the digital power box at 1% for heating. But, you will also need to remember that even if you drain the glycol from the jacket after cold crashing, if you use municipal water there will still be some glycol mix left in the jacket, albeit not much, but something to consider.

When I bought my medium BIAC it came with the old analog power box, hence my current setup today.

If you search my posts in this thread you can see all the different combinations I tried - TK500, TK2000, both in tandem, insulated lines, half-ass neoprene jacket, and what I was able to do to give you an idea.

Fuzzy-felt

Member

If you search my posts in this thread you can see all the different combinations I tried - TK500, TK2000, both in tandem, insulated lines, half-ass neoprene jacket, and what I was able to do to give you an idea.

Thanks for the advice. I'll check out your other posts on this.

By the way, I'd be looking to use this to lager. Perhaps not that important how long it takes to get down to lagering temperatures (I would only ramp it down a few degrees (°C) per day anyway), but it needs to be man enough to stay there.

xico

Well-Known Member

- Joined

- Jan 22, 2015

- Messages

- 328

- Reaction score

- 64

I ended up building a whirlpool arm out of an old 1/2" stainless racking cane and a few triclamp parts from brewhardware.com

This mounts to a top port and allows pumping from bottom port through the tube. The compression fitting in the middle is just snug so it can be moved up and down and rotated. Waiting on the current batch to finish before I can try it and I'll post a video.

I have made use of your suggestion and I recirculate through the racking valve. I use the bottom port to dump the trub before aeration and pitching. Thanks again for the contribution! It works great for whirlpooling hops as well. My last hefe, wit, and pale have been varying degrees of juicy. I don't recall if you said you added this too, but I am looking to put a 90degree elbow on the unit so the valve and hosing is perpendicular from the ground.

But I'm now looking to upgrade the brew process. Has anyone added a racking arm to the system? I would like to pull my wort from the middle of the kettle to maximize cooling and I like the idea of getting as much clear beer as possible.

I've also been looking at building/buying a mash/sparge distributor. Does anyone have any good ideas?

But I'm now looking to upgrade the brew process. Has anyone added a racking arm to the system? I would like to pull my wort from the middle of the kettle to maximize cooling and I like the idea of getting as much clear beer as possible.

I've got this racking arm on my BIAC and have been happy with the results. I'm not sure how much it helps with cooling but it's a pretty good size for transferring with little being left in the cone.

On a separate note for anyone that uses Beersmith, a new version was released this week which should more accurately work with the BIAC in terms of water usage. In the mash tun equipment profile there's a new field called "Mash Tun Addition" where you can add the volume of deadspace under the colander. That volume will then get added automatically to the first mash step.

Thank you limulus for the schematic and photos. I'm considering the same unit now. If you don't mind I have a few questions regarding the unit and your set up:

1. Do you use a glycol/water mix?

2. Your schematic shows a solenoid valve at the higher output port of the jacket. If that is so, can you tell me why you use a solenoid valve there? (I have a solenoid valve on the input port for the jacket.)

3. I'm confused by the glycol loop. Is this to assist with lessening the loss of glycol when disconnecting the chiller from the BIAC?

4. I didn't see a pressure gauge in the photos. Is this needed to keep the PSI range below 5 based on Nathan's recommendation?

Thank very much for your help on this!!!

Hey JB, I just saw this. I'm about to get on a conference call but I will come back and answer your questions today.

Well, the call is at 2:30, not 2:00, so I'm back to post answers below:

Thank you limulus for the schematic and photos. I'm considering the same unit now. If you don't mind I have a few questions regarding the unit and your set up:

1. Do you use a glycol/water mix? Yes, I can't remember the ratio, but it is on the glycol jug.

2. Your schematic shows a solenoid valve at the higher output port of the jacket. If that is so, can you tell me why you use a solenoid valve there? (I have a solenoid valve on the input port for the jacket.) Actually, it is a ball valve at the output of the jacket. It is on the exit hose so I can close it and not drip water/glycol all over the garage floor when I detach the hose. **Also, I have a small plastic bucket and a lid I bought at Home Depot to drain the glycol/water from the jacket into. I believe it is 2-gal. I fill the reservoir of the chiller and let it flow into the fermenter jacket. That takes about 2-gal and at that point the chiller reservoir is low and starting to suck air. I then fill reservoir with more water/glycol solution. I then have a total of 5-gal (2 in the fermenter and 3 in the reservoir of the chiller).

3. I'm confused by the glycol loop. Is this to assist with lessening the loss of glycol when disconnecting the chiller from the BIAC? The chiller has a pump that runs continuously. So, I made the loop following a plan I got from an actual brewery. There is a valve in the loop near the return to the reservoir that is just slightly closed so that it increases the pressure just a little but still allows the solution to flow through the loop and back to the reservoir. The leg that goes to the fermenter is before that valve. When the solenoid at the bottom of the fermenter opens the solution follows that leg since it is the path of least resistance. For my loop, I used braided tubing from Home Depot and Styrofoam insulation and duct tape.

4. I didn't see a pressure gauge in the photos. Is this needed to keep the PSI range below 5 based on Nathan's recommendation? There is just not enough pressure to damage anything and I've had that thing running for weeks. The brewery I got the plan from does use a pressure gauge. I think vacuums are the biggest danger to damaging the fermenter unless you have a fire hose connected to it.

BTW, you will need either a drip bucket or the neoprene jacket. That little white bucket under my fermenter is 1-gal and in summer when the humidity is high, that thing fills up every day.

Thank very much for your help on this!!![/quote]

JB_Brewing2

Well-Known Member

Well, the call is at 2:30, not 2:00, so I'm back to post answers below:

Thank you limulus for the schematic and photos. I'm considering the same unit now. If you don't mind I have a few questions regarding the unit and your set up:

1. Do you use a glycol/water mix? Yes, I can't remember the ratio, but it is on the glycol jug.

2. Your schematic shows a solenoid valve at the higher output port of the jacket. If that is so, can you tell me why you use a solenoid valve there? (I have a solenoid valve on the input port for the jacket.) Actually, it is a ball valve at the output of the jacket. It is on the exit hose so I can close it and not drip water/glycol all over the garage floor when I detach the hose. **Also, I have a small plastic bucket and a lid I bought at Home Depot to drain the glycol/water from the jacket into. I believe it is 2-gal. I fill the reservoir of the chiller and let it flow into the fermenter jacket. That takes about 2-gal and at that point the chiller reservoir is low and starting to suck air. I then fill reservoir with more water/glycol solution. I then have a total of 5-gal (2 in the fermenter and 3 in the reservoir of the chiller).

3. I'm confused by the glycol loop. Is this to assist with lessening the loss of glycol when disconnecting the chiller from the BIAC? The chiller has a pump that runs continuously. So, I made the loop following a plan I got from an actual brewery. There is a valve in the loop near the return to the reservoir that is just slightly closed so that it increases the pressure just a little but still allows the solution to flow through the loop and back to the reservoir. The leg that goes to the fermenter is before that valve. When the solenoid at the bottom of the fermenter opens the solution follows that leg since it is the path of least resistance. For my loop, I used braided tubing from Home Depot and Styrofoam insulation and duct tape.

4. I didn't see a pressure gauge in the photos. Is this needed to keep the PSI range below 5 based on Nathan's recommendation? There is just not enough pressure to damage anything and I've had that thing running for weeks. The brewery I got the plan from does use a pressure gauge. I think vacuums are the biggest danger to damaging the fermenter unless you have a fire hose connected to it.

BTW, you will need either a drip bucket or the neoprene jacket. That little white bucket under my fermenter is 1-gal and in summer when the humidity is high, that thing fills up every day.

Thank very much for your help on this!!![/quote]

Limulus,

Thank you very much for taking the time to address my questions. Everything is much clearer now. I believe this is the route I'll go. Thanks again for all your help!

Similar threads

- Locked

- Replies

- 15

- Views

- 3K

- Replies

- 17

- Views

- 2K

- Replies

- 7

- Views

- 685

- Replies

- 1

- Views

- 695