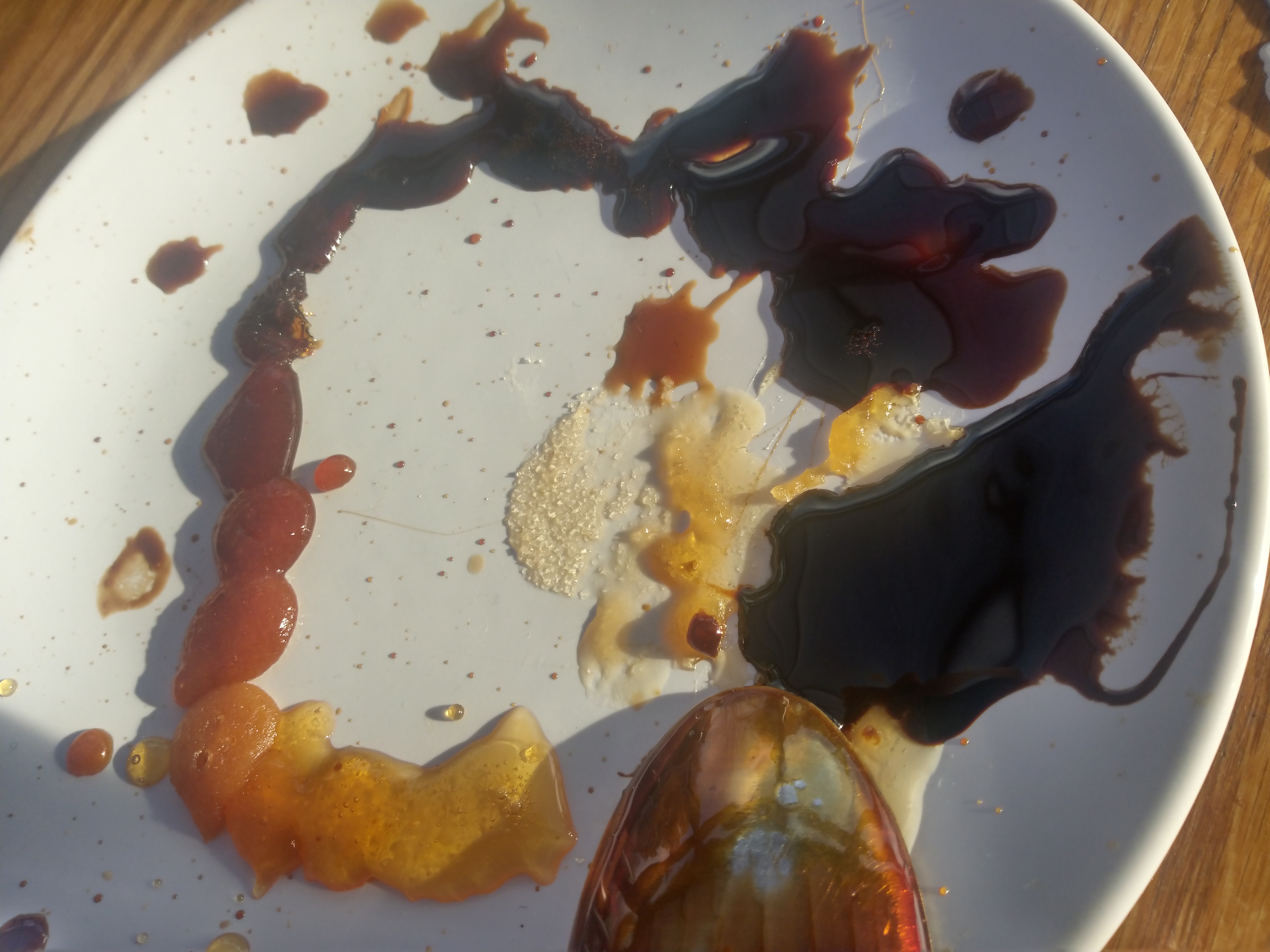

I also made a batch of #5, the color was spot on when tested on foil but it looked totally black in the jar. I added a pound of it to a dubbel a week into primary fermentation; the resulting beer has a wonderful aroma of raisins and hazelnuts and the distinctive flavors of luxardo cherries and toffee without even a hint of burnt sugar bitterness. The residual sweetness was a big concern for me, I didn't want to end up with a sugary sweet mess but the way it turned out seems perfect to my palate. I have put up about two dozen bottles to age.

This weekend I'm cooking up a double batch of #5 and canning it for use in the near future, it's truly wonderful stuff.

This weekend I'm cooking up a double batch of #5 and canning it for use in the near future, it's truly wonderful stuff.