resslerk

Well-Known Member

I did do some searching and couldn't find an answer... although I'm sure it is out there hiding! So if I'm missing it and you know where it is, please post the link.

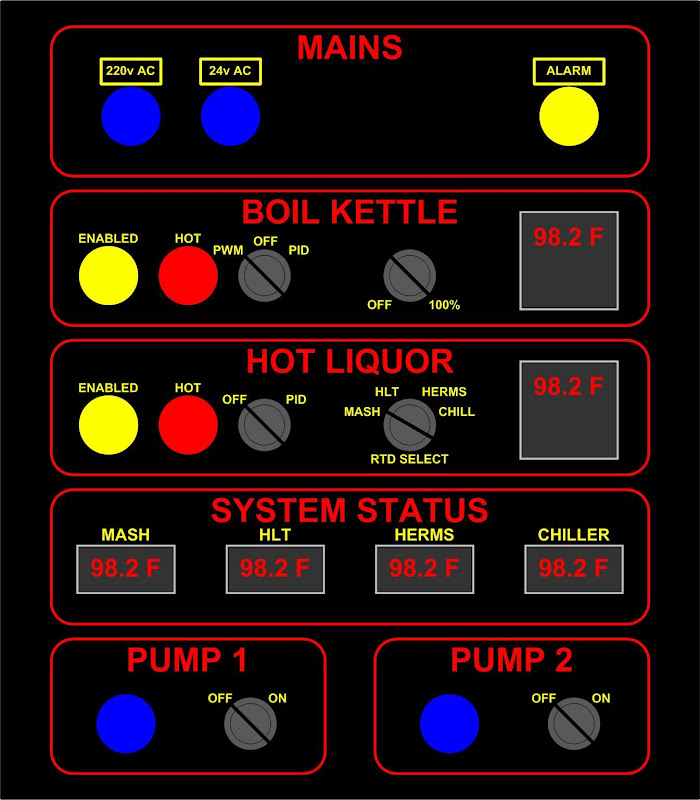

I'd like to add a 2nd RTD sensor to my system into Mash Tun. I already have one in my Boil Kettle and have a Auber PID controller. Essentially while mashing I want to be able to flip a switch and activate one sensor versus the other. What is the best way to do this? What would the wiring for the two RTD's tied to the switch look like?

I'd like to add a 2nd RTD sensor to my system into Mash Tun. I already have one in my Boil Kettle and have a Auber PID controller. Essentially while mashing I want to be able to flip a switch and activate one sensor versus the other. What is the best way to do this? What would the wiring for the two RTD's tied to the switch look like?