mpmccann

Well-Known Member

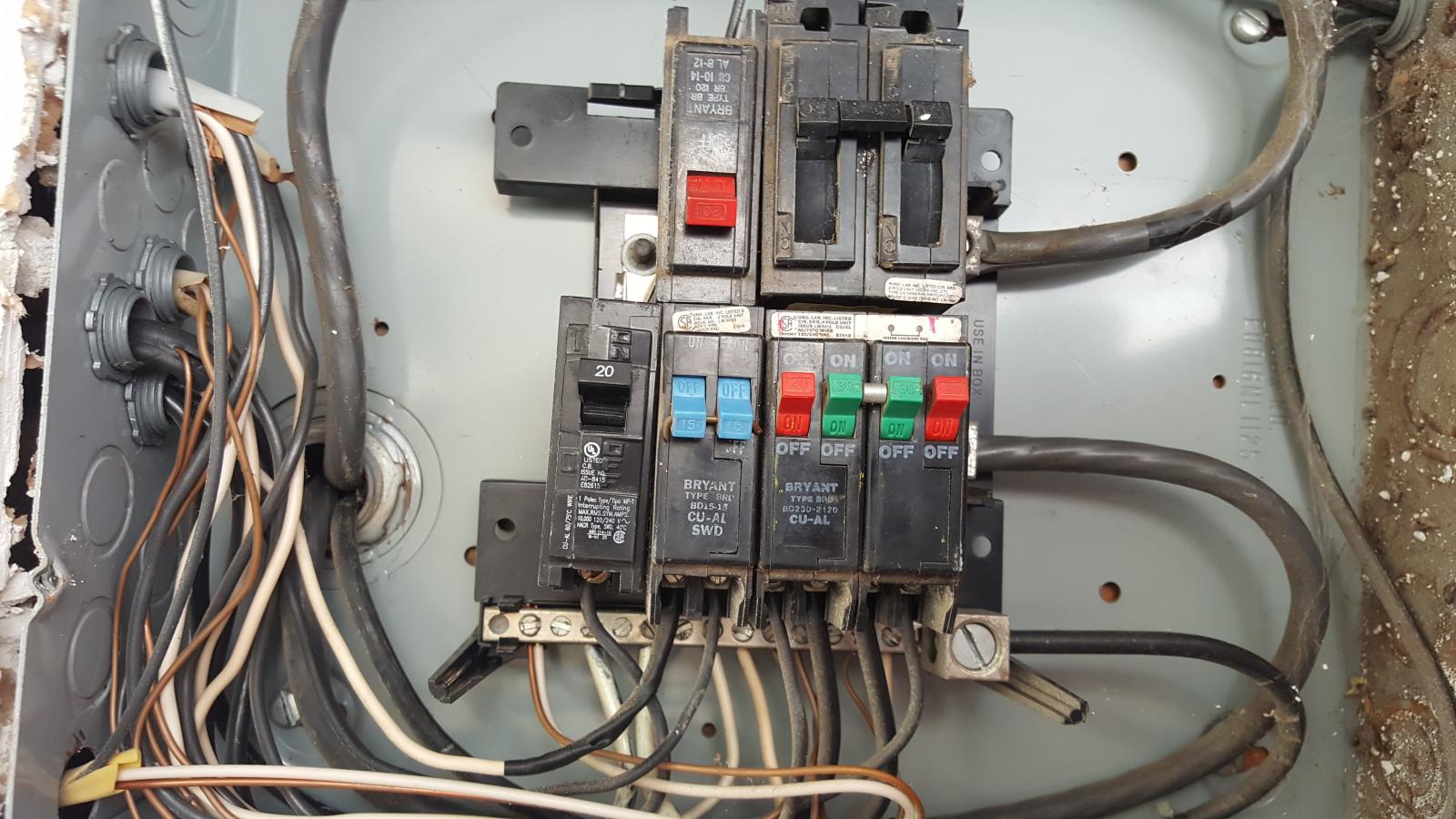

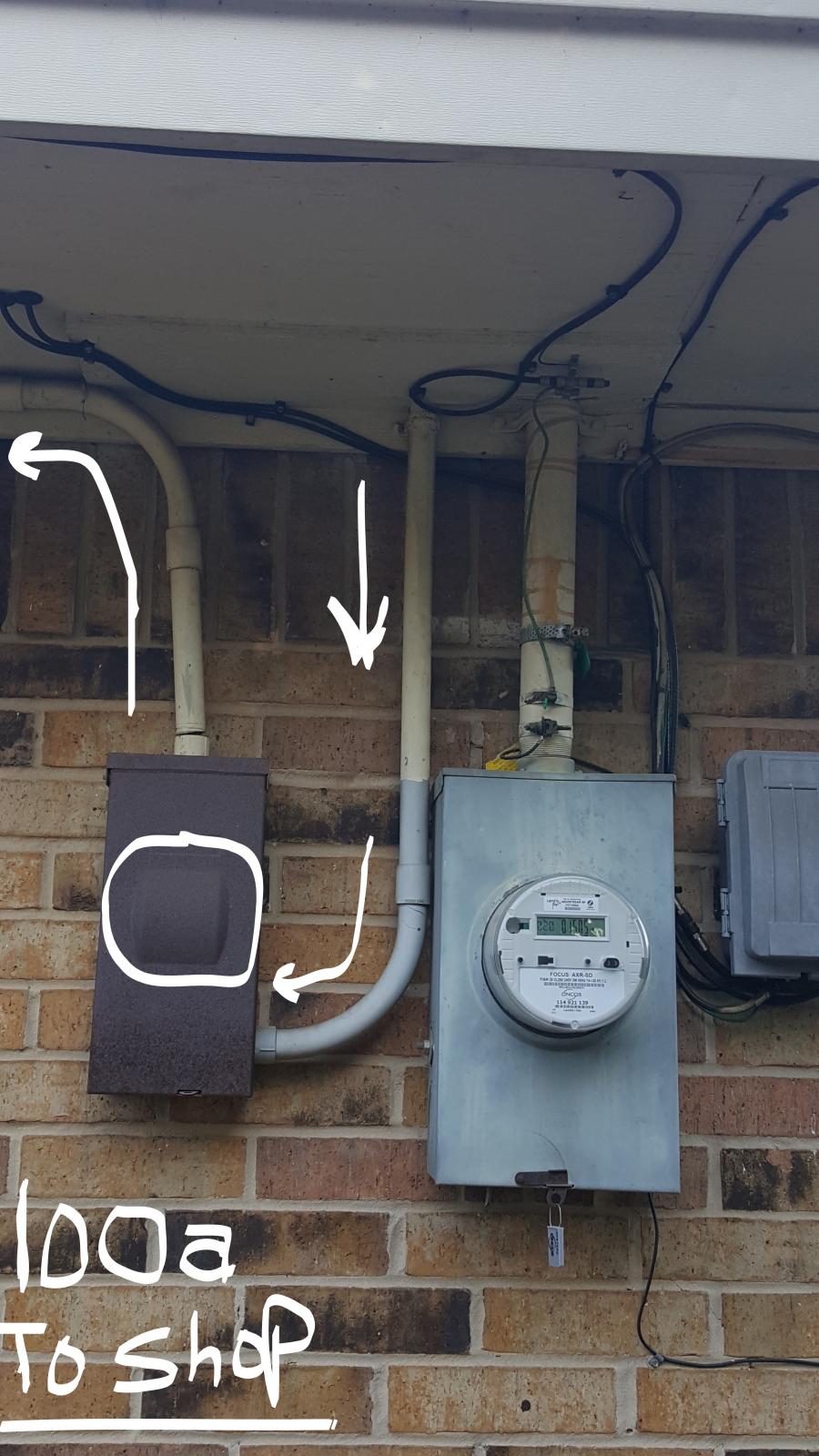

I just bought a new to me house built 1979. It has a detached shop which I want to dedicate part of to my brewery. I would like to get off propane and go all electric. I want to add two 5500 watt elements "only need one at a time" HLT and BK. I already use a 120v rims to control mash temps with a Chugger pump.

First question,

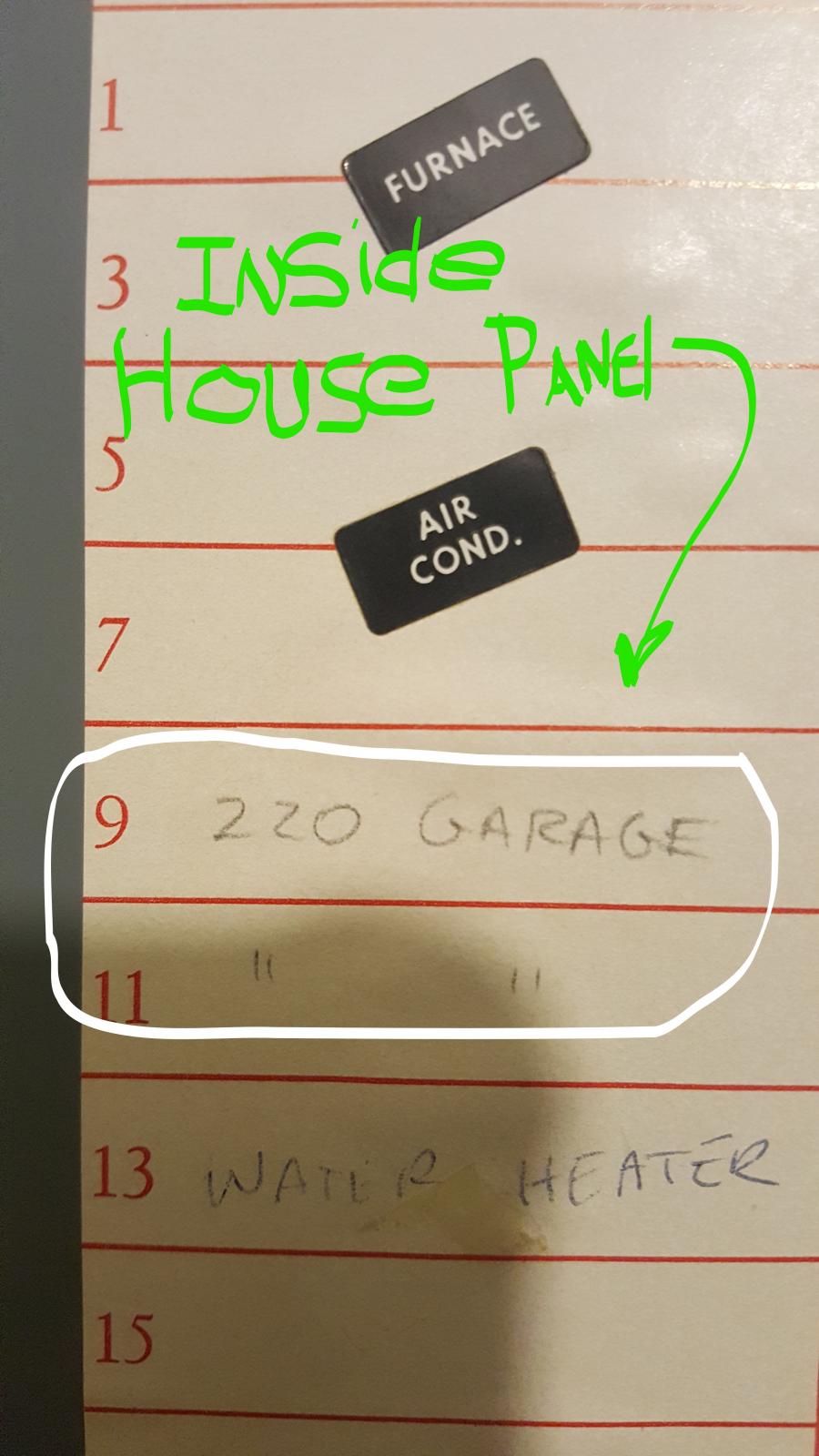

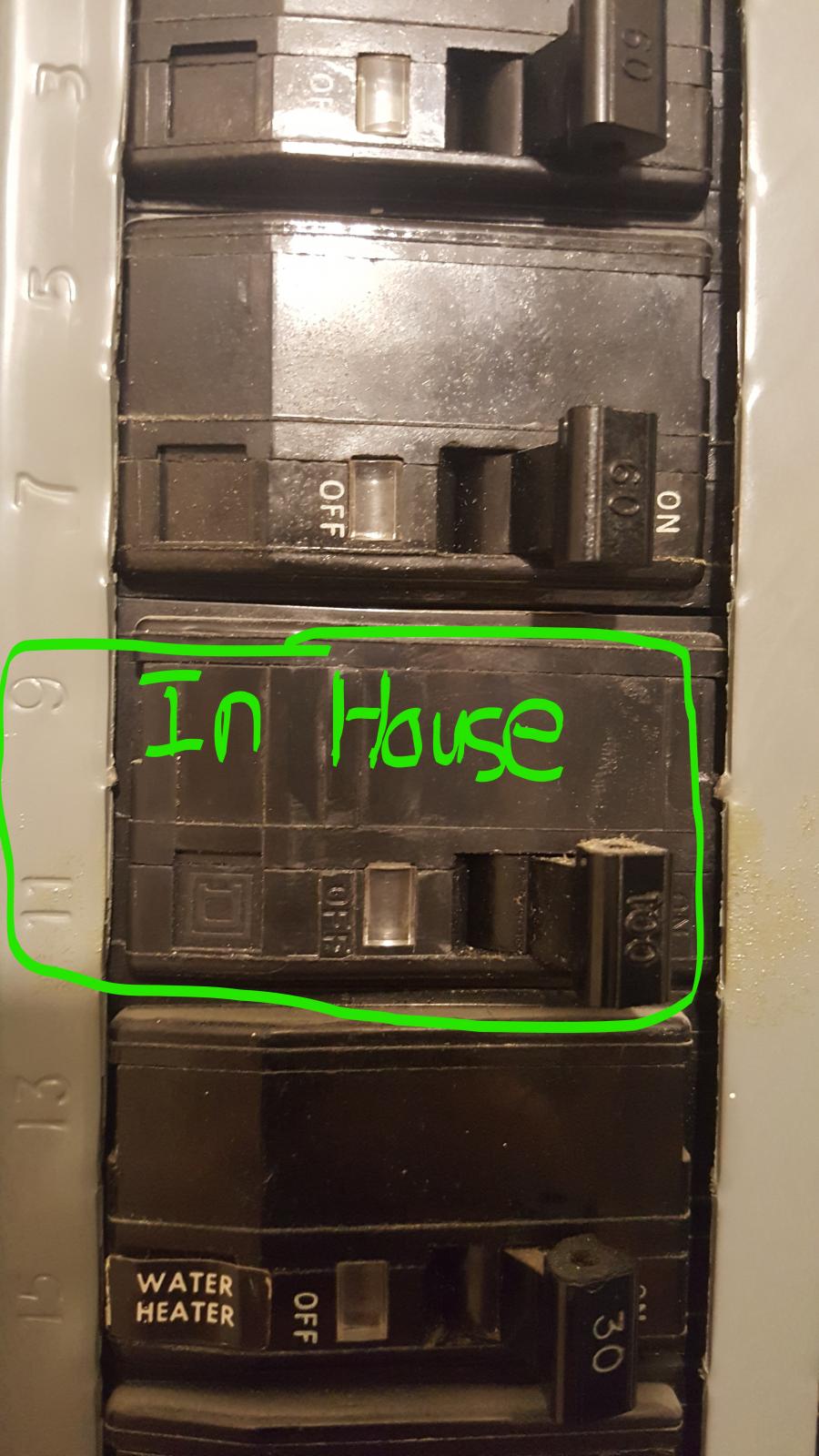

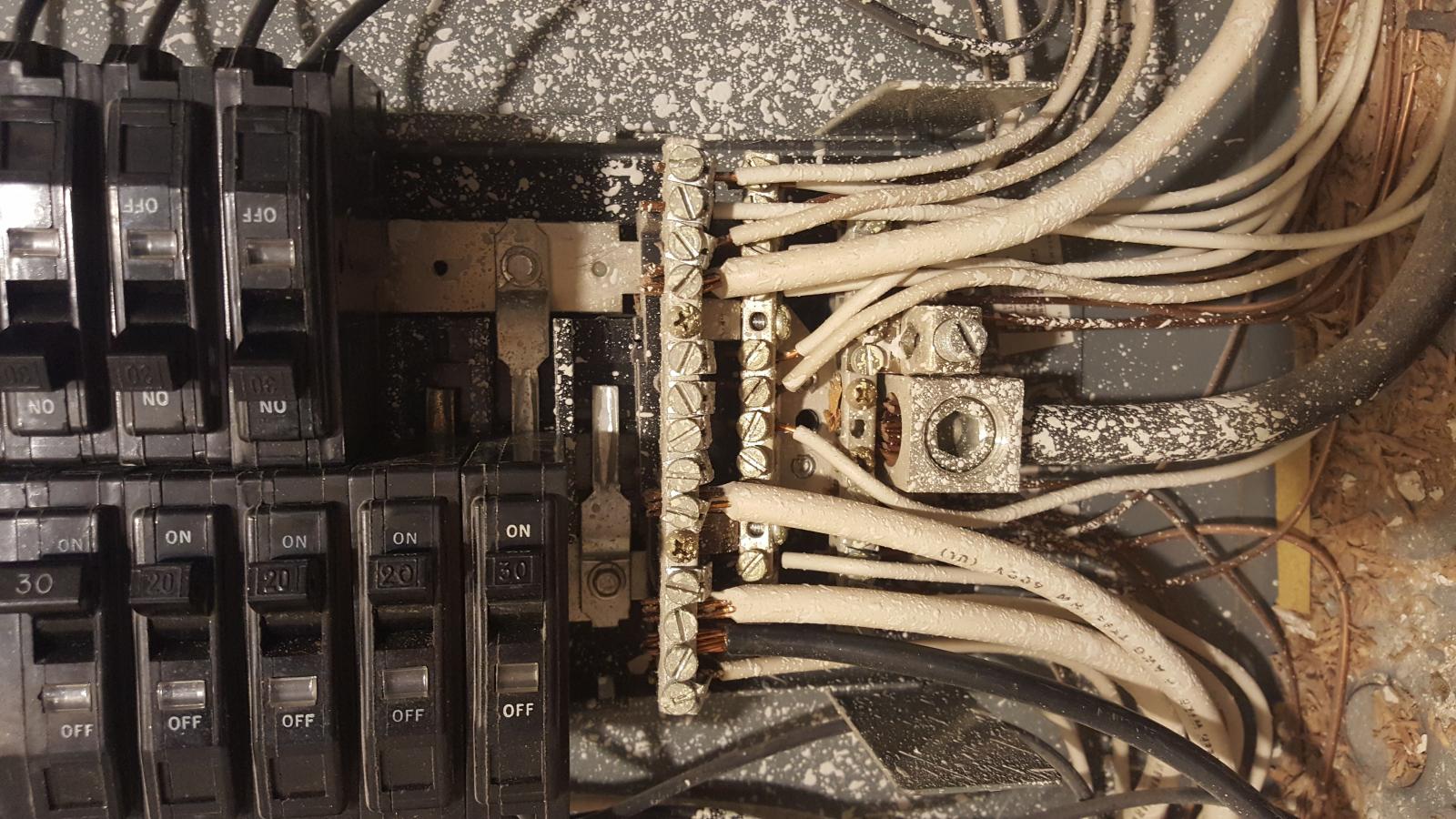

There is a old slanted three prong cloths dryer receptacle. I measure voltage from ground to both blades and get 120vac on each and 240vac accross the two. It is on a 50 amp breaker. Shouldn't that be a 30 amp breaker? I believe that style receptacle is only rated for 30 amps correct?

This plug is also not in the ideal location for brewing but could work in a pinch. I would need to run an extension cord from it.

Second question,

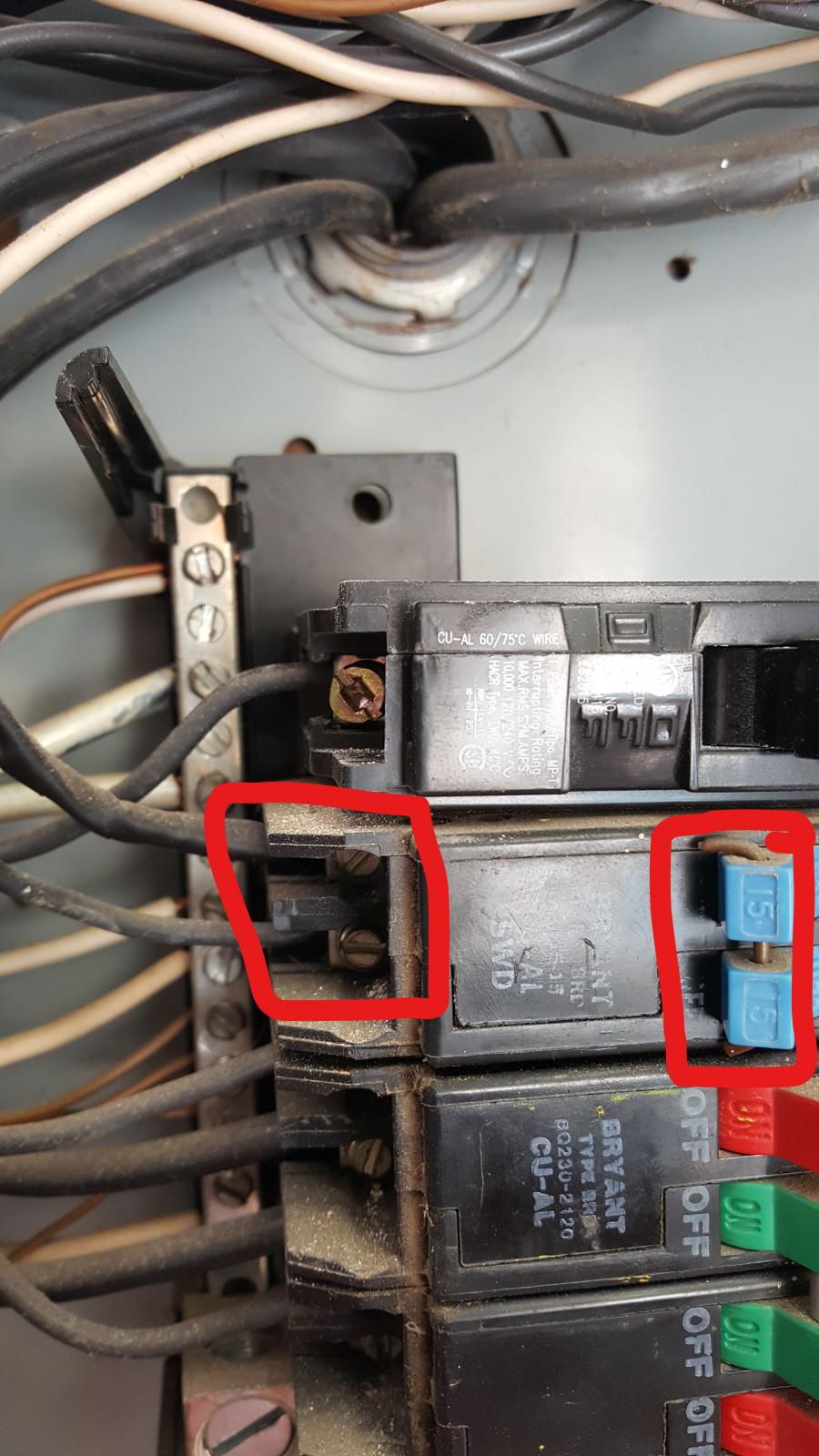

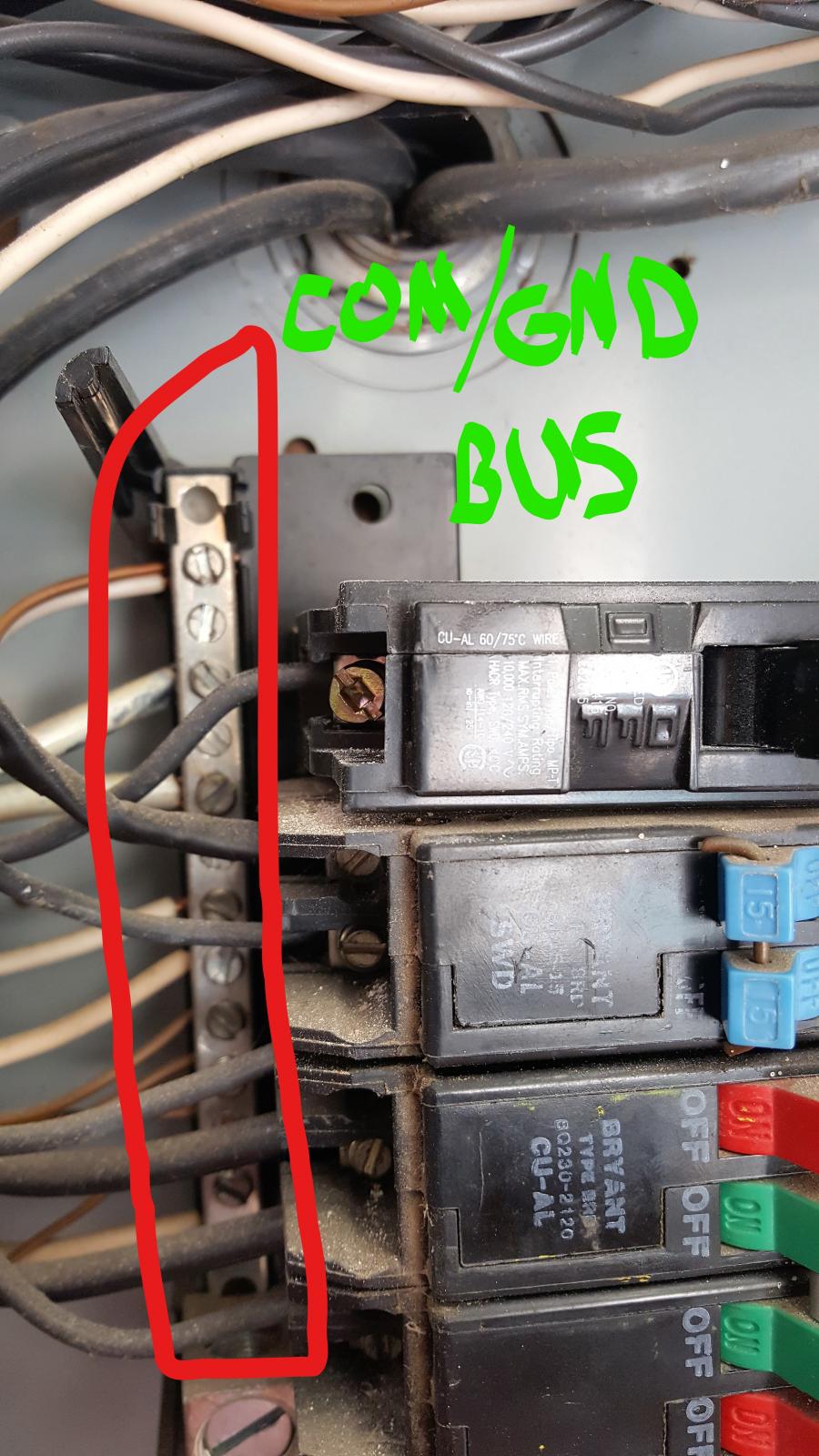

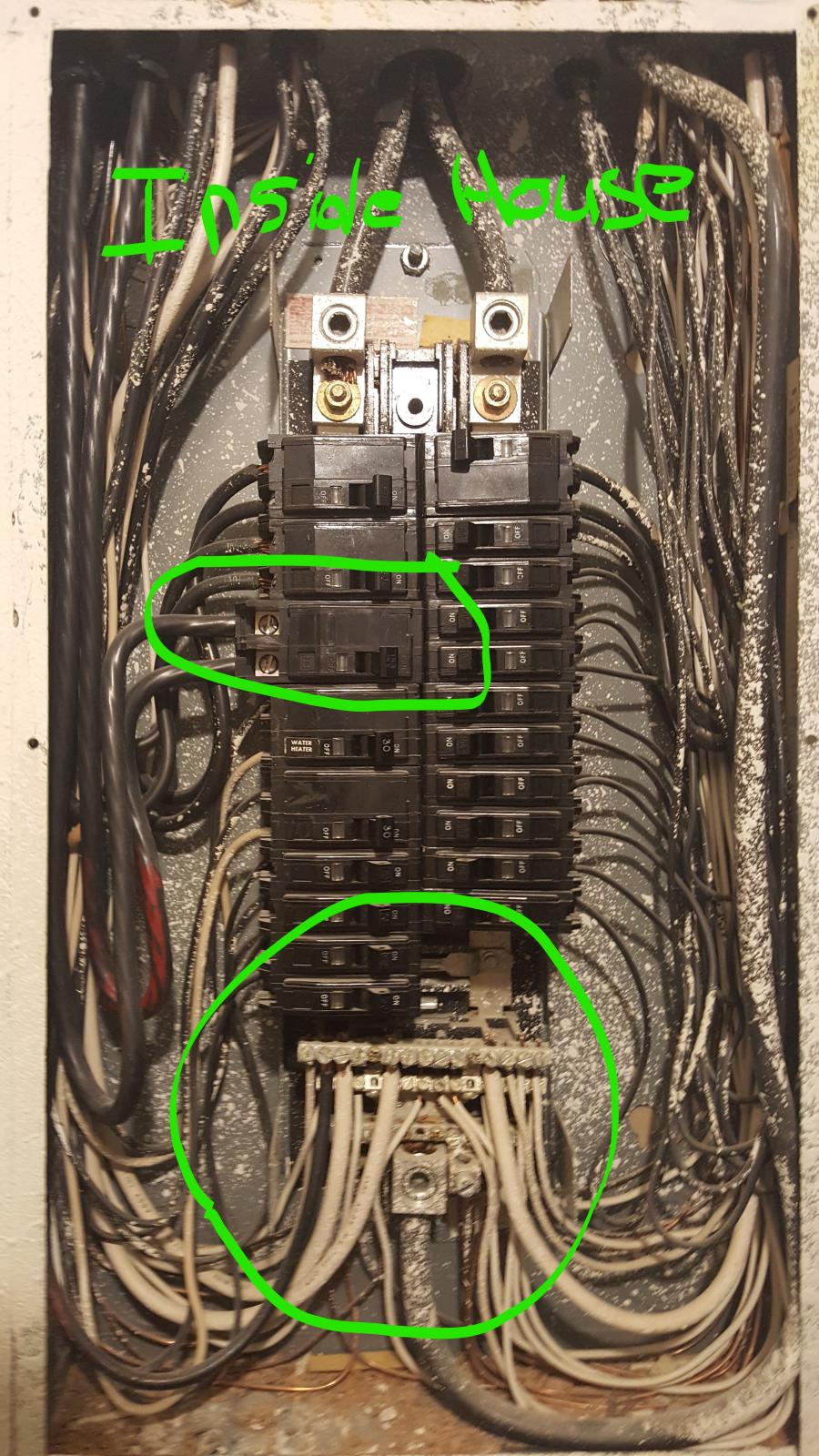

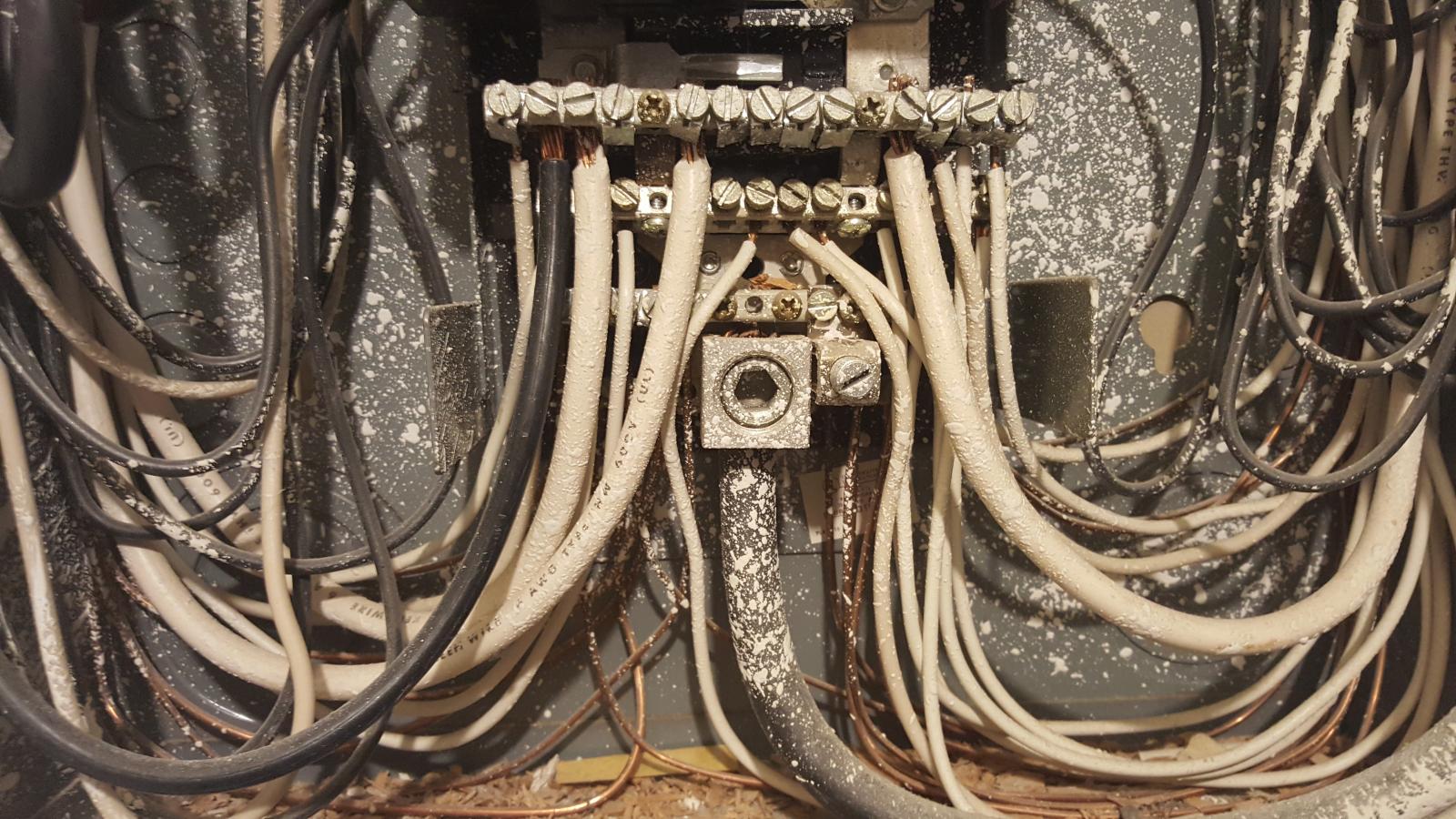

There is also an old attic style fan that was used as a cooling or exhaust fan to the shop on the far wall, and a much better location for brewing plus ventilation through the wall. The motor is rated for 230vac, so I'm thinking just add the appropriate receptacle there. The motor is seized up and bad anyway. When I measure the voltage on those wires I get 120vac to ground on both but when I measure across I don't get 240vac like I would expect, I only get a few volts, why is it not 240v like on the other circuit? It is also on a double 30 amp breaker which are tied together with a bar. In other words, you have to switch both at the same time in breaker box. Thanks and sorry for the long winded post, just trying to get a handle on this electrical stuff and any help would be much appreciated.

Cheers,

Matt...

First question,

There is a old slanted three prong cloths dryer receptacle. I measure voltage from ground to both blades and get 120vac on each and 240vac accross the two. It is on a 50 amp breaker. Shouldn't that be a 30 amp breaker? I believe that style receptacle is only rated for 30 amps correct?

This plug is also not in the ideal location for brewing but could work in a pinch. I would need to run an extension cord from it.

Second question,

There is also an old attic style fan that was used as a cooling or exhaust fan to the shop on the far wall, and a much better location for brewing plus ventilation through the wall. The motor is rated for 230vac, so I'm thinking just add the appropriate receptacle there. The motor is seized up and bad anyway. When I measure the voltage on those wires I get 120vac to ground on both but when I measure across I don't get 240vac like I would expect, I only get a few volts, why is it not 240v like on the other circuit? It is also on a double 30 amp breaker which are tied together with a bar. In other words, you have to switch both at the same time in breaker box. Thanks and sorry for the long winded post, just trying to get a handle on this electrical stuff and any help would be much appreciated.

Cheers,

Matt...