I figured this would be better documented in here.

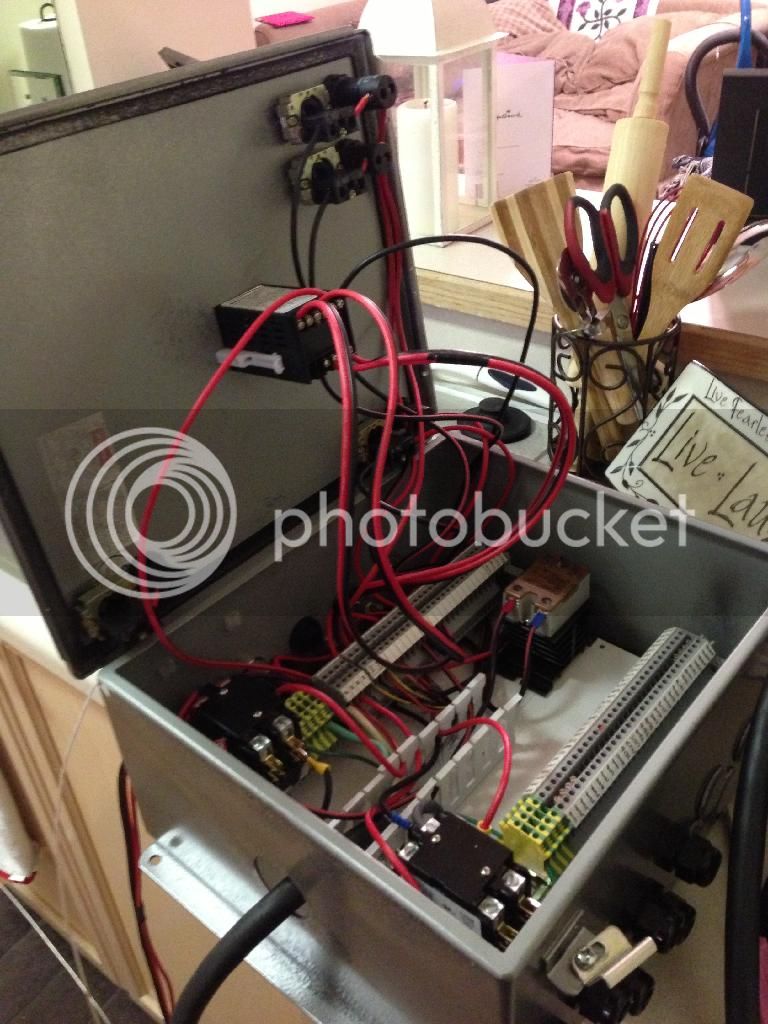

I decided to do this properly. Enclosures are pretty costly and I wanted to only do things once but be able to expand and upgrade as necessary. I scored this enclosure off ebay for $75 shipped. it's 14" x 12" x 6":

It has 4 set of "connectors" combining 6 or so connectors into one block as well as all of the grounds being wired together. The caps on the sides are pre punch conduit holes which will make mounting plugs and running wire in and out a breeze. I am currently using Google Draw to map my layout as well as wiring schematic.

(Image updates as I update the doc, don't hate if something is currently wrong as I am still designing!)

Have everything layed out. Ordered 50ft each of red and black 12 AWG wire to get everything wired up. Gonna raid my wire bucket to get what bits I need for ground wire and if I come up short, Ill grab some from HD. Still gotta add in the alarm tonight.

For now, the 2nd element will no go through the panel. It would require another SSR, wiring, plugs, etc. For now, I will just attach a normal 120v plug on it and plug it in to hurry up to mash temps and when I boil.

The actual brew process still needs a little work but will be based off of my "BrewRack". I live in a small apartment in atlanta and have to make use of what little room we have. Still need to do some more arranging but it will use one pump and gravity from the mash tun up top, and from the BK down to the counterflow chiller.

I decided to do this properly. Enclosures are pretty costly and I wanted to only do things once but be able to expand and upgrade as necessary. I scored this enclosure off ebay for $75 shipped. it's 14" x 12" x 6":

It has 4 set of "connectors" combining 6 or so connectors into one block as well as all of the grounds being wired together. The caps on the sides are pre punch conduit holes which will make mounting plugs and running wire in and out a breeze. I am currently using Google Draw to map my layout as well as wiring schematic.

(Image updates as I update the doc, don't hate if something is currently wrong as I am still designing!)

Have everything layed out. Ordered 50ft each of red and black 12 AWG wire to get everything wired up. Gonna raid my wire bucket to get what bits I need for ground wire and if I come up short, Ill grab some from HD. Still gotta add in the alarm tonight.

For now, the 2nd element will no go through the panel. It would require another SSR, wiring, plugs, etc. For now, I will just attach a normal 120v plug on it and plug it in to hurry up to mash temps and when I boil.

The actual brew process still needs a little work but will be based off of my "BrewRack". I live in a small apartment in atlanta and have to make use of what little room we have. Still need to do some more arranging but it will use one pump and gravity from the mash tun up top, and from the BK down to the counterflow chiller.