andrewmaixner

Well-Known Member

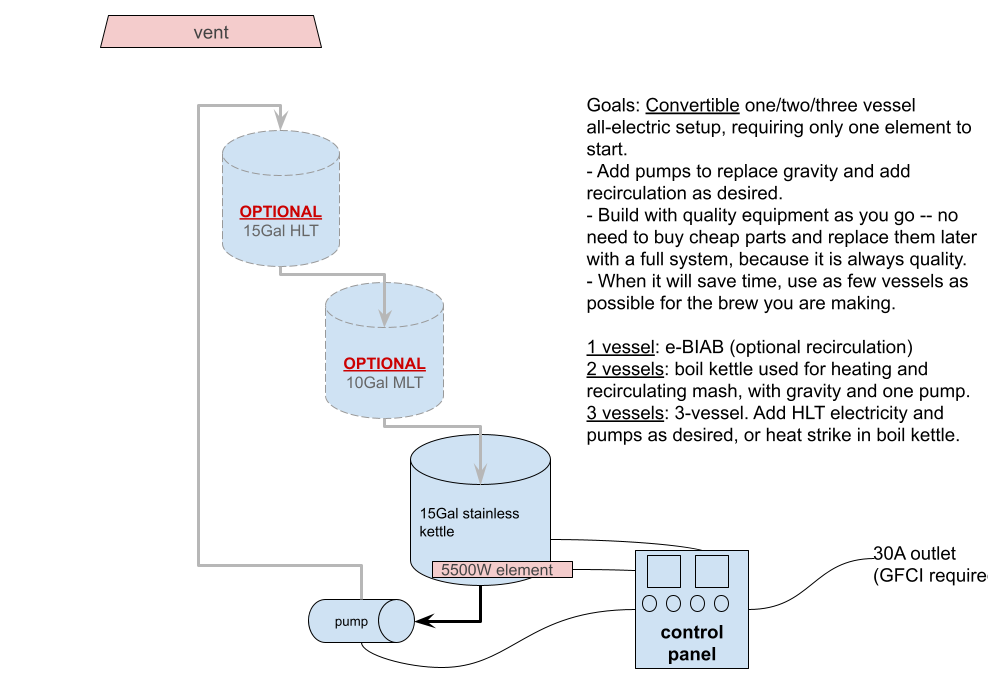

I figured that this can't really be a new idea that I thought of while considering what kind of indoor system to build: an electric setup that can do all of the common methods, depending on how much and how strong of a wort you are making, temperature step requirements, etc:

- 1 vessel BIAB, optional re-circulation

- 2 vessel recirculating (like Brutus-20)

- traditional 3 vessel

I this would let someone start at the low end and slowly build up the system, without sacrificing quality in the older components, as everything could be seamlessly integrated in the next-larger system.

I did a quick sketch:

Anyone already do something like this?

- 1 vessel BIAB, optional re-circulation

- 2 vessel recirculating (like Brutus-20)

- traditional 3 vessel

I this would let someone start at the low end and slowly build up the system, without sacrificing quality in the older components, as everything could be seamlessly integrated in the next-larger system.

I did a quick sketch:

Anyone already do something like this?