I have been wondering this for some time now, and it has started to bug me that I haven't been able to come up with a legitimate answer!

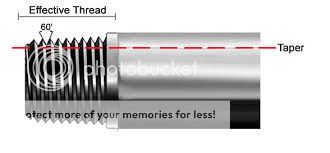

For my weldless bulkhead assemblies, I have always used the short nipple+silicone O-ring+ desired FTP fitting. For example: on my MLT I have a 1/2" FPT compression fitting which screws on to the nipple and pushes the silicone O-ring against the wall to create a seal. The compression fitting is then connected to cPVC piping which connects to my manifold.

However, every time I look online and see complete bulkhead assemblies offered by various suppliers, I see that a locknut threads on to the nipple to create the seal with the O-ring, then a coupling is screwed on to provide a connection to the dip tube or whatever may be present. Why is the coupling used at all? Why not piece together a diptube that has FTP threads (which is what I have done) ?

I'm only asking this because I am making changes to my equipment, and if there is any benefit to this setup, I would gladly conform to this way of assembly... but I have failed to see why!

Thanks for your help,

Jay

For my weldless bulkhead assemblies, I have always used the short nipple+silicone O-ring+ desired FTP fitting. For example: on my MLT I have a 1/2" FPT compression fitting which screws on to the nipple and pushes the silicone O-ring against the wall to create a seal. The compression fitting is then connected to cPVC piping which connects to my manifold.

However, every time I look online and see complete bulkhead assemblies offered by various suppliers, I see that a locknut threads on to the nipple to create the seal with the O-ring, then a coupling is screwed on to provide a connection to the dip tube or whatever may be present. Why is the coupling used at all? Why not piece together a diptube that has FTP threads (which is what I have done) ?

I'm only asking this because I am making changes to my equipment, and if there is any benefit to this setup, I would gladly conform to this way of assembly... but I have failed to see why!

Thanks for your help,

Jay