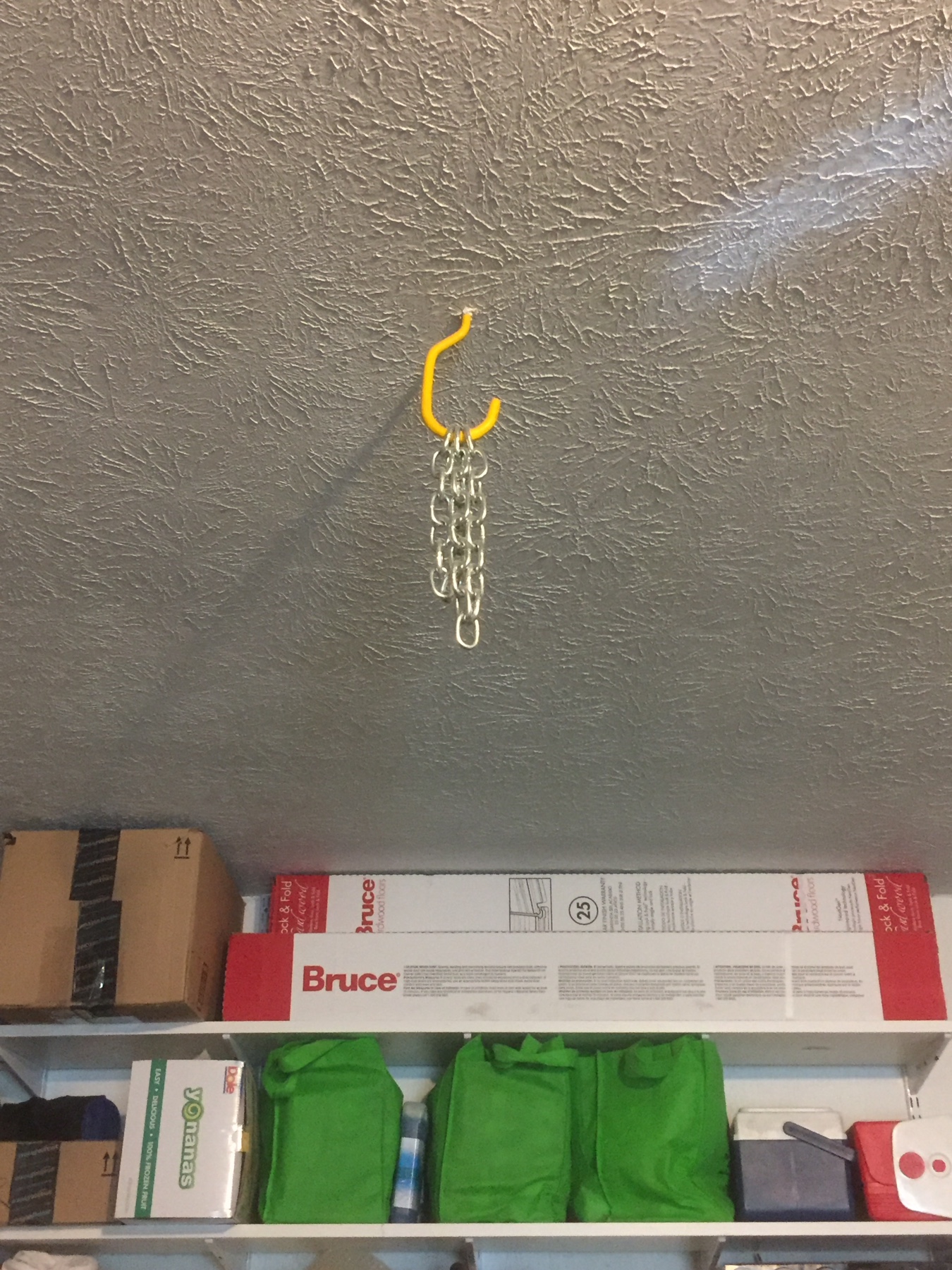

I just bought a pulley but not sure where to attach it. I have cross boards attach to floor joists. I can just hang the pulley on one of those (pictured) but I'm not sure if it will be strong enough. I could use the floor joist, I'm just not sure what the safest way to attach the pulley to it would be. Would an eye bolt through the bottom be strong enough or should I drill through the side and buy a big carabineer?

View attachment 1508005897213.jpg

View attachment 1508005897213.jpg