Auger

Well-Known Member

I've been getting a specific off-flavor in all of my stouts and porters, which I'm thinking is due to a drop in mash pH from using dark grains. I don't have a pH meter. I don't get this flavor at all in lighter beers, and have good success with bitters and kolsch brewing. I sent in a sample ot ward labs:

Which, as I understand it, roughly corroborates my theory (as much as possible without actually testing mash pH, anyway). My water has pretty low alkalinity and mineral content, good for lighter beers, less so for dark beers with heavier roasted grains.

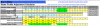

I'm not trying to replicate any specific water profile, and honestly I'd rather not mess with water additions if at all possible; or as necessary, as little as possible. I'm a little stuck now with how to improve from here. Using Bru'n Water, it looks like I need to add some base to my mash, but not sure how to go about it. It sounds like chalk is going to be too much work to mess around with dissolving under pressure. Here's the water adjustment sheet set up for "black malty" profile:

Am I on the right track, or should I be looking elsewhere?

Which, as I understand it, roughly corroborates my theory (as much as possible without actually testing mash pH, anyway). My water has pretty low alkalinity and mineral content, good for lighter beers, less so for dark beers with heavier roasted grains.

I'm not trying to replicate any specific water profile, and honestly I'd rather not mess with water additions if at all possible; or as necessary, as little as possible. I'm a little stuck now with how to improve from here. Using Bru'n Water, it looks like I need to add some base to my mash, but not sure how to go about it. It sounds like chalk is going to be too much work to mess around with dissolving under pressure. Here's the water adjustment sheet set up for "black malty" profile:

Am I on the right track, or should I be looking elsewhere?