I've never used this yeast before, even tho' it's a standard. It has been fermenting for 6 days; 5 if you don't count the first day lag. The temperature is currently 64°F, and it's fermenting in a plastic bucket. It's probably time to rack it to a carboy, but should I also warm it a little to wake it up? OG was 1.056 and now it's at 1.017. I expected it to finish at 1.010 or 1.009. Perhaps I should just leave it alone for another week.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

US-05 yeast seems to be stuck at 70% attenuation

- Thread starter z-bob

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

BrewnWKopperKat

ʘ‿ʘ

Perhaps I should just leave it alone for another week.

When I brewed with US-05 in the 62-65F range, it was slow. But it's also a good yeast for "weekend brewers" as it's almost always done two weeks after pitching the yeast.

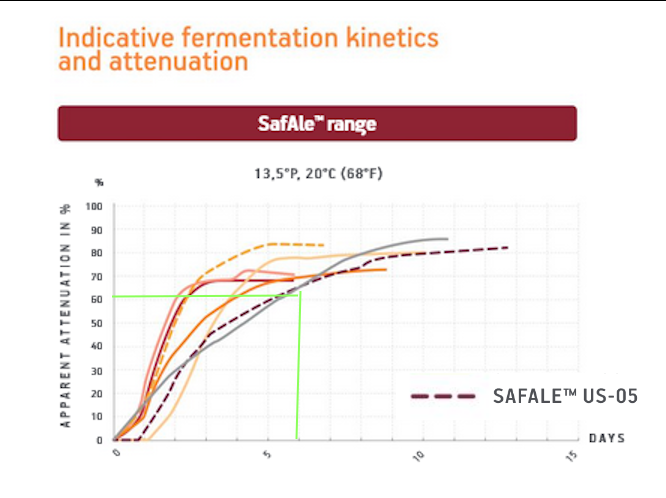

Here's an annotated chart from Fementis Tips & Tricks (p 28).

Why not leave it in the (closed) bucket, until ready to package?Perhaps I should just leave it alone for another week.

The need for secondaries has been pretty much debunked (except for a few cases).

Never too late.I've never used this yeast before, even tho' it's a standard.

I'd start raising the temps soon at this point, to 68F and maybe a few days at 70-72F when that starts to slow down.

^yup^ and after a ~week I'd warm it up a bit

fwiw, I typically run US-05 at 66°F and after a week to 10 days I bump the temperature up to 68°F for a few days before moving the process along (typically a soft crash, dry hop, then hard crash before kegging).

Cheers!

fwiw, I typically run US-05 at 66°F and after a week to 10 days I bump the temperature up to 68°F for a few days before moving the process along (typically a soft crash, dry hop, then hard crash before kegging).

Cheers!

G_robertus

Well-Known Member

1.009 is a bit low imo, but 1.011-1.012 should be about what you expect depending on your recipe. Did you mash warm or brew a stout? Or add lactose or maltodextrin? Those things will increase your FG. Nevertheless waiting a total of two weeks for medium strength brews is never a bad idea. Warning up your vessel isn't a bad idea either.

I move it from the bucket to a carboy to leave most of the trub behind. Then I bottle straight from that carboy instead of transferring to a bottling bucket. I did just one carboy start to finish for a while, and it's evolved into this; I'd rather unavoidably add oxygen while the yeast is still active (although I suppose the priming sugar serves the same purpose.) If I try to bottle straight from the fermenting bucket (or carboy) I end up with too much gunk in the bottles.Why not leave it in the (closed) bucket, until ready to package?

The need for secondaries has been pretty much debunked (except for a few cases).

My second vessel is more of a bright tank than a secondary; also if I'm not going to bottle it right away I'm more comfortable with it being in a carboy under an air lock.

This is my process, and I've used US05 many dozens of times. It's 1 of my go-to yeasts, not because it has great flavor or adds certain tones, but because it's reliable and neutral.^yup^ and after a ~week I'd warm it up a bit

fwiw, I typically run US-05 at 66°F and after a week to 10 days I bump the temperature up to 68°F for a few days before moving the process along (typically a soft crash, dry hop, then hard crash before kegging).

Cheers!

It's dropped another gravity point. Apparently it's still chugging, just slowly, and I'm being impatient. I will warm it up to about 68 and give it another week to finish.

I mashed at 150°F for an hour. No lactose or anything like that, but this was my first time using cornstarch as an adjunct. I pitched the yeast at 70° and immediately moved it to my cool basement, which apparently is in the low 60s.1.009 is a bit low imo, but 1.011-1.012 should be about what you expect depending on your recipe. Did you mash warm or brew a stout? Or add lactose or maltodextrin? Those things will increase your FG. Nevertheless waiting a total of two weeks for medium strength brews is never a bad idea. Warning up your vessel isn't a bad idea either.

I think I'm just used to faster-fermenting yeasts, or at least ones that go at a steadier pace and don't slow way down for the last few points. If it was still dropping at one week (and apparently it is, very slowly) I wouldn't have been worried. When it was at 1.107 for 24 hours I panicked

Warming up a little should help getting her finished as far as she can.It's dropped another gravity point. Apparently it's still chugging, just slowly, and I'm being impatient. I will warm it up to about 68 and give it another week to finish.

As you know, once the beer starts to get clear, that's a sign the yeast is dropping out. As long as she stays warmish (say, above around 60°F) she'll still be conditioning for a while, but don't expect much, if any, attenuation anymore.

I see your point. But oxygen-wise I am not sure how much the yeast takes up while she's not replicating anymore.My second vessel is more of a bright tank than a secondary; also if I'm not going to bottle it right away I'm more comfortable with it being in a carboy under an air lock.

As long as you keep the siphon off the bottom, well above the trub line, there should no gunk being transferred.If I try to bottle straight from the fermenting bucket (or carboy) I end up with too much gunk in the bottles.

It also helps to stick one of those diverter caps on the bottom of the siphon, so the beer flows in from above.

I siphon from the brew bucket to a keg that way, starting somewhere in the middle between the beer level and the (estimated) trub line, lowering the siphon slowly as the beer level recedes. Once there's about 1-2 gallons left I start tilting the bucket slowly toward the side the siphon is clamped along, to keep the siphoning well deep. As soon as I see a slight stream of trub being sucked up, I stop the transfer. There's not much beer left, often not even enough to swirl up the yeast/trub cake.

Now when you're bottling you're probably priming each bottle separately, yes?

BrewnWKopperKat

ʘ‿ʘ

US-05 is often described as having low/medium flocculation. I also found that it tends to be loose (or "fluffy") on the bottom of the fermenter. So if you're going to use the "tip the fermenter" technique when transferring, it helps to move the fermenter a day or two in advance and use a small wedge to tilt the fermenter.I move it from the bucket to a carboy to leave most of the trub behind. Then I bottle straight from that carboy instead of transferring to a bottling bucket. I did just one carboy start to finish for a while, and it's evolved into this; I'd rather unavoidably add oxygen while the yeast is still active (although I suppose the priming sugar serves the same purpose.) If I try to bottle straight from the fermenting bucket (or carboy) I end up with too much gunk in the bottles.

Are you by chance using a Tilt or similar to measure the gravity? These things don't read right when yeast or hop schmutz is stuck to them. The gravity might be several points lower.

If not... yeah, just warm it up and wait a few more days.

If not... yeah, just warm it up and wait a few more days.

Yes, I am using a Tilt.Are you by chance using a Tilt or similar to measure the gravity? These things don't read right when yeast or hop schmutz is stuck to them. The gravity might be several points lower.

If not... yeah, just warm it up and wait a few more days.

Yes, a spoonful of table sugar in each bottle. The size of the spoon depends on the size of the bottle. I've got a little stainless steel funnel made for filling liquor flasks; it's perfect for priming bottles and it goes a lot faster than you'd expect.Now when you're bottling you're probably priming each bottle separately, yes?

I'm doing it the same way! Quick and easy solution.Yes, a spoonful of table sugar in each bottle. The size of the spoon depends on the size of the bottle. I've got a little stainless steel funnel made for filling liquor flasks; it's perfect for priming bottles and it goes a lot faster than you'd expect.

- Joined

- Mar 10, 2021

- Messages

- 2,730

- Reaction score

- 2,353

What sort of beer is it?

I had a stout I used US-05 with that didn't attenuate as fully as it did the pale ales and IPA's I usually do with it. But then again, none of the stouts I did last year attenuated fully with any of the yeast I used for them.

For me I'm pretty sure it was more water issues since I don't do much if any corrections. And evidently stouts are more particular about that.

I had a stout I used US-05 with that didn't attenuate as fully as it did the pale ales and IPA's I usually do with it. But then again, none of the stouts I did last year attenuated fully with any of the yeast I used for them.

For me I'm pretty sure it was more water issues since I don't do much if any corrections. And evidently stouts are more particular about that.

It's somewhat between a cream ale and an American blonde ale, and the color is probably a little darker than either of those should be. Not bitter enough to call it pale ale. In any case, it's not anywhere close to being a stout.What sort of beer is it?

I had a stout I used US-05 with that didn't attenuate as fully as it did the pale ales and IPA's I usually do with it. But then again, none of the stouts I did last year attenuated fully with any of the yeast I used for them.

For me I'm pretty sure it was more water issues since I don't do much if any corrections. And evidently stouts are more particular about that.

STATS:

Original Gravity: 1.054

Final Gravity: 1.009

ABV (standard): 5.89%

IBU (tinseth): 26.61

SRM (morey): 7.11

Mash pH: 5.41

FERMENTABLES:

5.5 lb - US Pilsner (68.8%)

1.5 lb - US Aromatic Malt (18.8%)

1 lb - Cornstarch (12.5%)

HOPS:

12 g - Columbus, Type: Pellet, AA: 14, Use: Boil for 30 min, IBU: 22.23

1 oz - Hallertau Tradition (Germany), Type: Pellet, AA: 4.5, Use: Boil for 5 min, IBU: 4.38

OTHER INGREDIENTS:

6 ml - Phosphoric acid (85%), Type: Water Agt, Use: Mash

1 tsp - Irish Moss, Time: 10 min, Type: Fining, Use: Kettle

Last edited:

- Joined

- Mar 10, 2021

- Messages

- 2,730

- Reaction score

- 2,353

I'd be a guessing at the water chemistry stuff. But 6ml of 85% phosphoric acid seems a tad high to me. But only because I've never considered using acid to modify my water. So far I'm just dealing with the minerals and whether in chloride or sulfate form.

Probably isn't though for 4 gallons.

Probably isn't though for 4 gallons.

My tapwater tastes good but has extremely high bicarbonates. 1 ml of concentrated H3PO4 per gallon of strike water seems to work well. I used to buy RO water, but settled on just adding acid and a pinch of K-Meta to my local water. I started with 5.5 gallons of water, and I rounded-up 5.5ml to 6.I'd be a guessing at the water chemistry stuff. But 6ml of 85% phosphoric acid seems a tad high to me. But only because I've never considered using acid to modify my water. So far I'm just dealing with the minerals and whether in chloride or sulfate form.

Probably isn't though for 4 gallons.

That should work fine.My tapwater tastes good but has extremely high bicarbonates. 1 ml of concentrated H3PO4 per gallon of strike water seems to work well.

Just as a caution, I'd dilute that 85% stock to 10% or so. It's much easier to work with for routine adjustments that way, and reduces measuring inaccuracies.

I simply hate working with concentrated acids, so I try minimize exposure to those. Measuring our 18 ml of Starsan concentrate (for 3 gallons of working solution) is the most I want to be exposed to it, and over the years had a few small mishaps doing that. And I'm pouring from a small (on-hand supply) bottle, not the jug.

Similar threads

- Replies

- 20

- Views

- 2K

- Replies

- 12

- Views

- 2K

- Replies

- 98

- Views

- 3K