philipCT

Brewniversity student

- Joined

- May 10, 2013

- Messages

- 771

- Reaction score

- 171

Is the beer getting too cold?

The TRUE commercial coolers function on a constant cool/defrost cycle. The compressor cycles on and runs until a thermostat adjustable (cut out) temperature is reached IN the evaporator,...

raouliii:

Thanks so much for this post. It seems after reading this that the thing may be doing exactly what It's supposed to be doing. I'll monitor some liquid temps and see where I am, but the beer is a bit too cold for my preference. I would like to see it at about 38F, but it's my impression that it's closer to 32F.

As for the evap tray and drain tube, I'm going to be testing that whole area today. I've had the unit turned off for 24 hours so I can really go at it.

Anyway, I'm really relieved after reading this thread because it seems that you guys have all had the same issues and most have resolved them. Once I get these issues handled, I know it's going to be a monster unit.

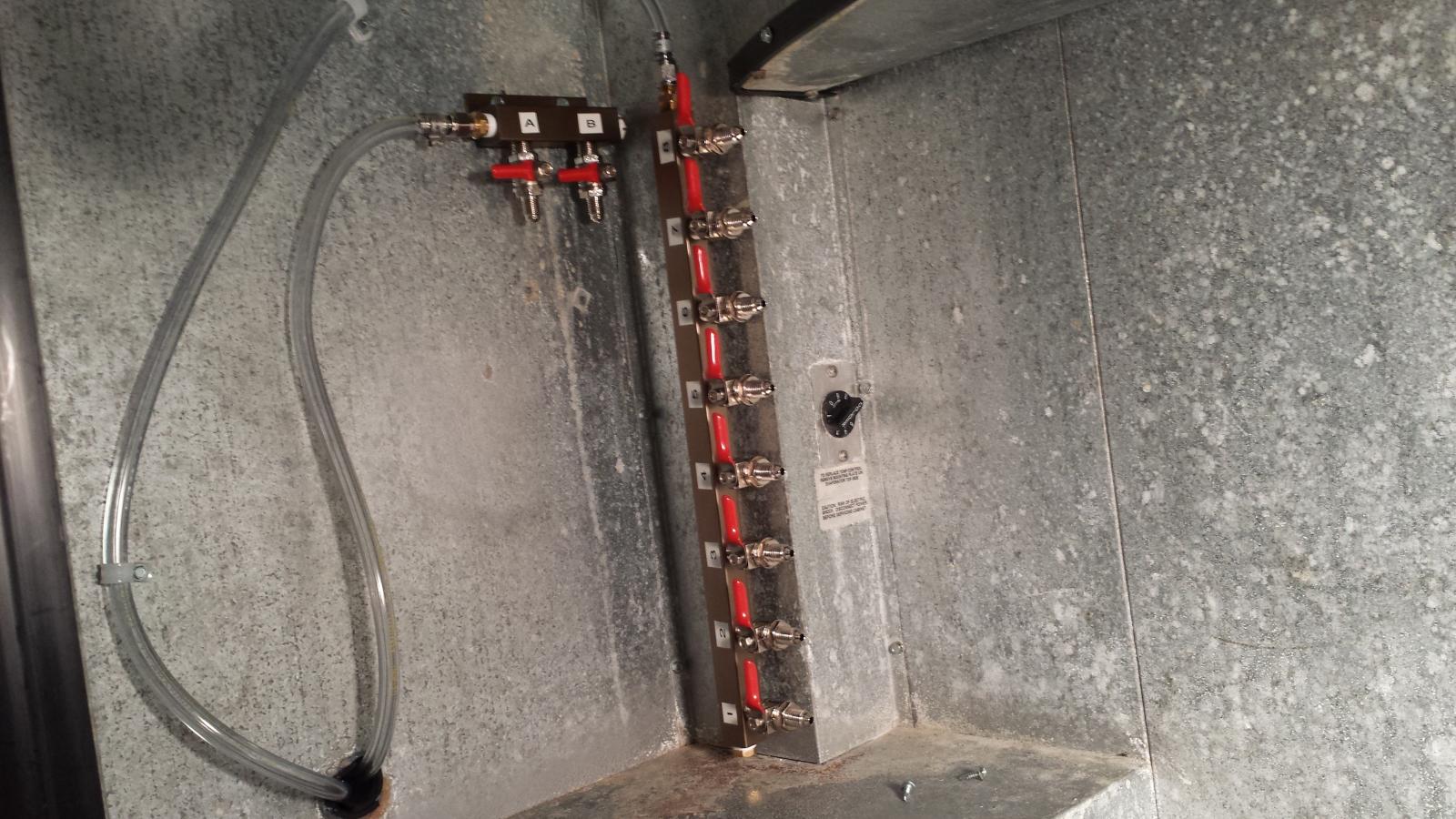

I planning to build a bar around it, so that it's an under-bar unit. Here's a shot of it in position in the tap room area outside the brew-studio.