homebrewdude76

Well-Known Member

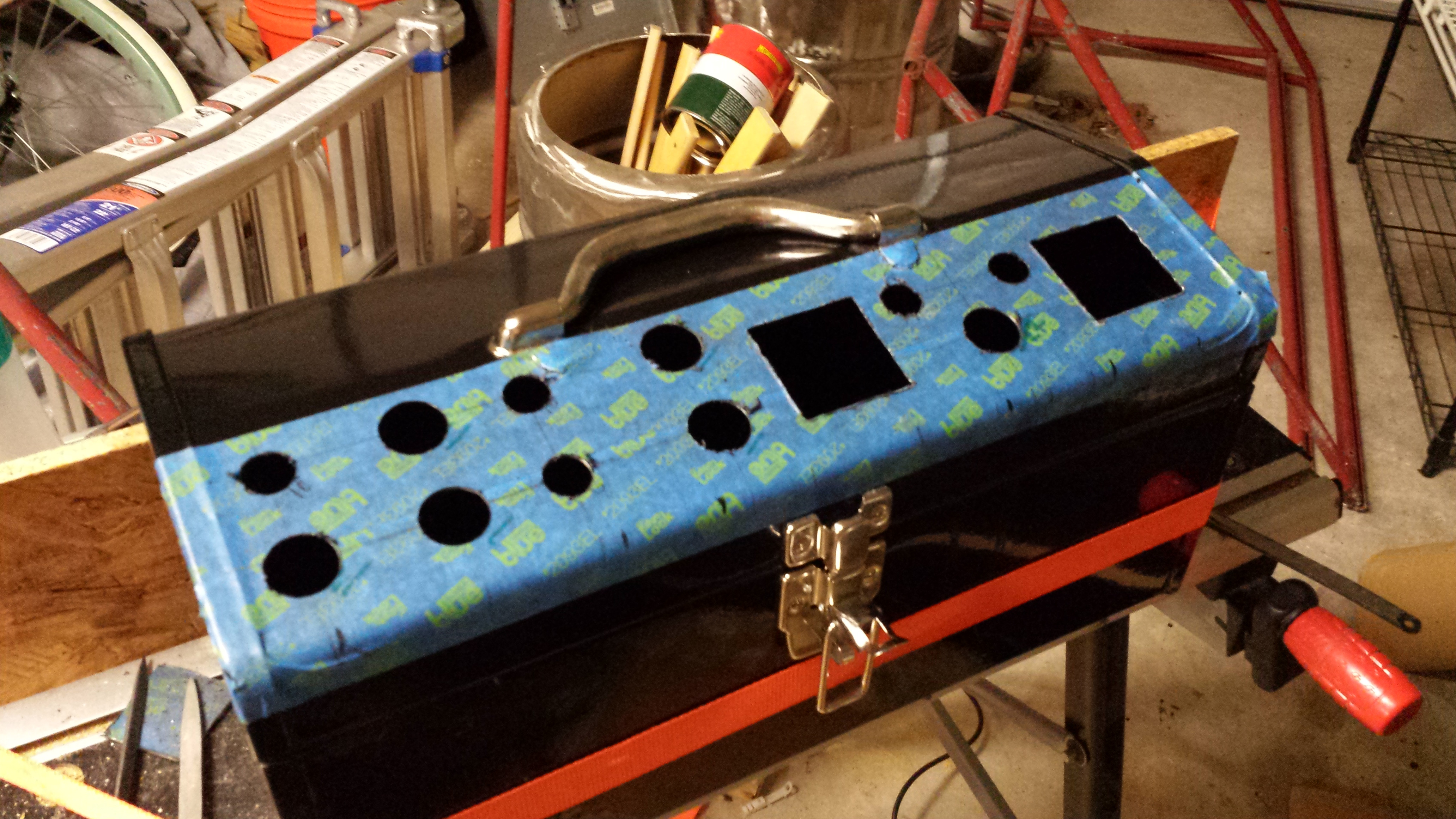

I have various greenlee punches and hole saws. Circles should not be an issue.

But I have 4 PID squares 1 rectangle for Amp/Volt and 2 rectangle for temp.

I don't own a good jig saw?

I do own an aircompressor and die grinders.

But I think the cuts need to be accurate?

But I have 4 PID squares 1 rectangle for Amp/Volt and 2 rectangle for temp.

I don't own a good jig saw?

I do own an aircompressor and die grinders.

But I think the cuts need to be accurate?