apache_brew

Well-Known Member

A friend of mine lent me his old keggle mash tun (1/4 bbl squatty keg welded to a 1/2 bbl keg).

I'm currently brewing with 2 vessels and 1 pump (full volume, MT above boil kettle, gravity drain into BK, pump suction from BK back into MT with Autosparge).

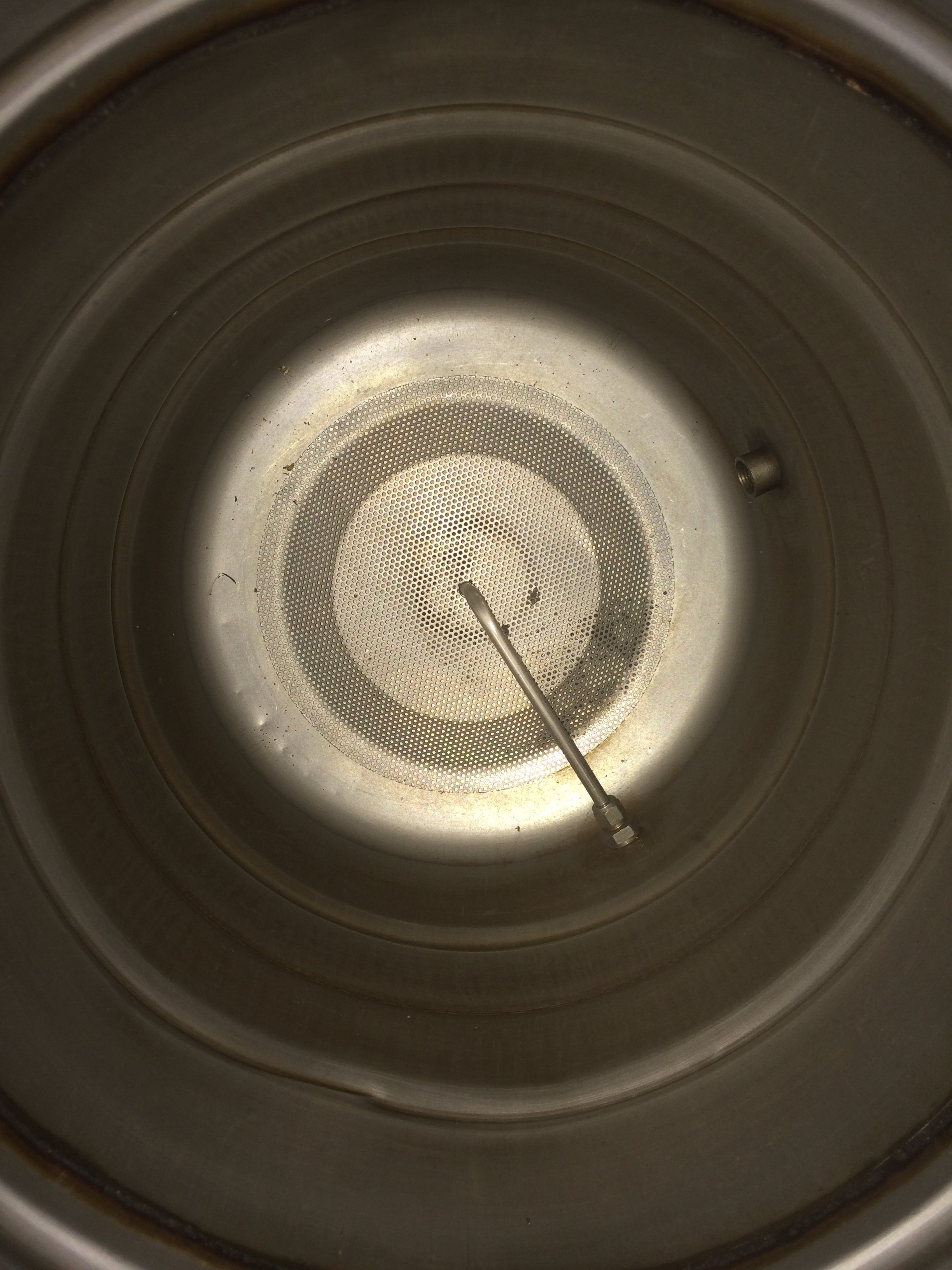

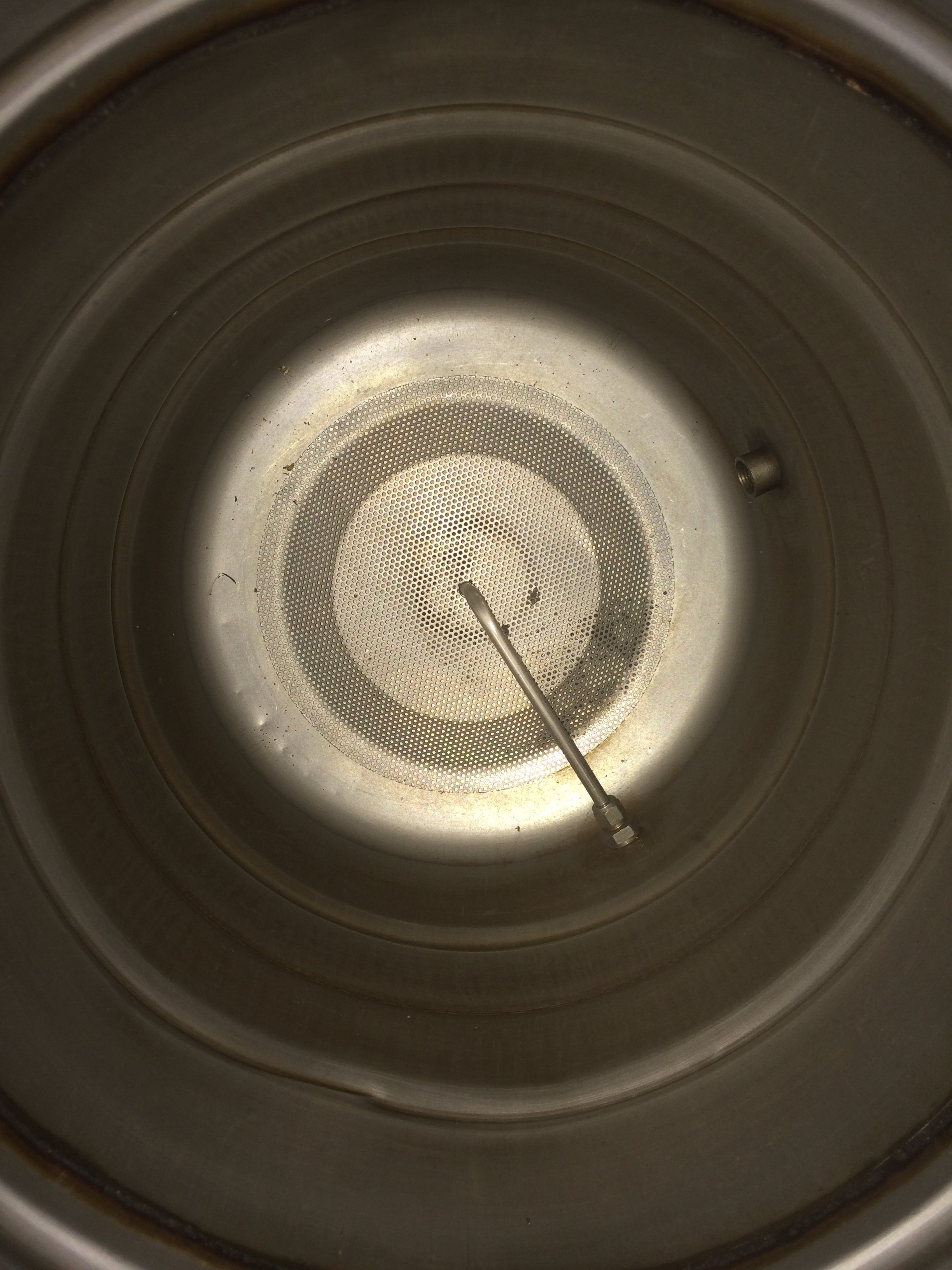

I'm currently brewing 11~12 gallon batches but noticed that when the grain bill goes over 30~35 lbs on 1.065+ OG beers, I keep getting stuck mashes and poorer efficiencies. My hopes were to use the new to me Frankenkeggletun to do 1/2 bbl batches and grain bills nearing 55lbs, but I'm thinking if I try to use my same brewing method, I'll have a real difficult time doing anything consistent. I'm currently crushing my grains slightly tighter than a credit card (no feeler gauges yet sorry). My thought was to swap out the dog dish/frisbee false bottom for a Jaybird style one that creates a full diameter filter bed in hopes of creating more surface area for wort to flow through the grain bed. Any thoughts on if this would allow me to use the taller mash tun effectivly with my brewing style? (Brutus 20, Blichmann Breweasy etc..) My alternate idea would be to get another mash tun (26 gallon ss pot, 100 qt recatangular cooler with mesh bag, etc).

Thanks

I'm currently brewing with 2 vessels and 1 pump (full volume, MT above boil kettle, gravity drain into BK, pump suction from BK back into MT with Autosparge).

I'm currently brewing 11~12 gallon batches but noticed that when the grain bill goes over 30~35 lbs on 1.065+ OG beers, I keep getting stuck mashes and poorer efficiencies. My hopes were to use the new to me Frankenkeggletun to do 1/2 bbl batches and grain bills nearing 55lbs, but I'm thinking if I try to use my same brewing method, I'll have a real difficult time doing anything consistent. I'm currently crushing my grains slightly tighter than a credit card (no feeler gauges yet sorry). My thought was to swap out the dog dish/frisbee false bottom for a Jaybird style one that creates a full diameter filter bed in hopes of creating more surface area for wort to flow through the grain bed. Any thoughts on if this would allow me to use the taller mash tun effectivly with my brewing style? (Brutus 20, Blichmann Breweasy etc..) My alternate idea would be to get another mash tun (26 gallon ss pot, 100 qt recatangular cooler with mesh bag, etc).

Thanks