Curious to know how much you saved sourcing it yourself vs. buying their pre packed kit (not assembled, just the parts)

Well - a couple of factors play into my decision to source it myself - so your mileage may vary.

I am in Canada. But my mom lives close to the border of Point Roberts, WA, so I was able to take advantage of free/cheap on Amazon, BargainFittings, etc and have stuff shipped to a mail depot in Point Roberts.

Some of the smaller components (relays, lights, switches, etc) were way cheaper by ordering on Ebay or Amazon.

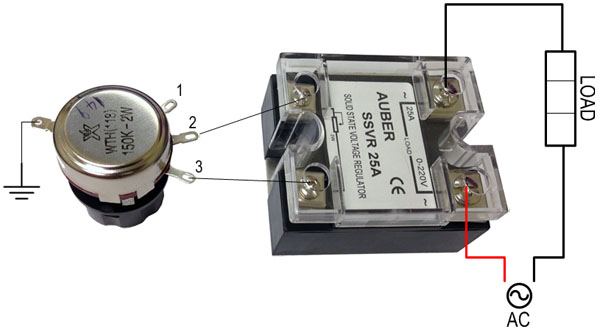

I used the same PIDs, but opted for the Auber timer instead of the Omega (huge price difference).

So my build is not an exact "clone" but it's pretty close.

The one thing I would totally recommend you buy from Kal even if you're sourcing your own parts would be the wiring kit. I definitely spent more than what he charges for my wire, connectors, etc.

It was a bit of a logistical challenge tracking all the packages and remembering exactly what parts I needed. You also have to have the time to shop around for deals.

I estimate (having given up on keeping exact track) that my control panel, all in, cost me about $700-800 to build.

Oh, and if you don't mind the panel not being exactly like Kal's, go for one of these meters:

http://www.ebay.ca/itm/180920422127?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

It does both amps and volts, still looks good, and is WAY easier to install. It also does not require a voltage converter and transformer, and you only need one, so you'll save ~$50 in parts.

I had a lot of trouble with the recommended ammeter (fried a couple of them, and one of the voltage converters). I now have a standalone volt meter and this combo meter in my panel since the holes were already cut.