sandyeggoxj

Well-Known Member

Well time to start my build. My kettles came in today and more stuff is on the way. The short version: 30-gallon kettles for the average 1/2bbl batch. Semi-automated BCS-462 controlled eHerms single tier brewery. I am building this to be a badass homebrew rig and scaleable to a 1-bbl pilot system in the next couple years when I go pro.

Kettles are made by Stout Tanks and Kettles out of PDX. I shipped them to the local brewery who had a loading dock. This cut my freight in half. I would highly suggest doing something like this if you decide to order from Stout.

Here is what I ordered:

Boil Kettle:

BK30TW-TI-SG-EL1. (2240). 30 Gal. Brew Kettle with (1) 1.5in. TC Port for electric element w/1in. NPS adapter, Thermowell, Tangential Inlet, Sight Glass, (2)3/4in. valves, (2) 1/2in. hose barbs, clamps/gaskets

HLT:

HL30TW-RHC-SG-EL1-XP. (Custom). 30 Gal. Hot Liquor Tank with Thermowell, RAISED HERMS Coil, Sight Glass,(1) Element Port with 1" NSP adapter, (1) Upper Port, (1)3/4in. Valve, (3) 1/2in. Hose Barbs, clamps/gaskets

MLT:

MT30TW-RF-BO (476). 115L Mash Tun with Bottom Outlet, Thermowell, Recirculation Fitting, (1)19mm Valve, (2) 1/2in. Hose Barbs, Clamps/Gaskets

Sparge Arm:

SP12SA. (720). Sparge Arm, 12in. long, with 2 clamps/gaskets, (1) 1.5in. end cap

I will total up all my costs once I get a little bit further in. I will post it up here in this first post.

And on to the pictures!

Here they are in the back of my pickup truck:

First look:

I had questions about the thermowell that it came with. This answered my questions. It is about 3" deep and has 1/2"NPT threads. It is welded in place so inside the kettles it is completely sanitary. I will just need a 1/2"npt x 1/4" compression to hold the temperature probes in place.

This is the sparge arm that came with the setup. It has a bunch of holes in the bottom for fly sparging:

And now for some brew porn. It came with more tri-clamps and gaskets but some were installed on the kettles at the time I took the pictures.

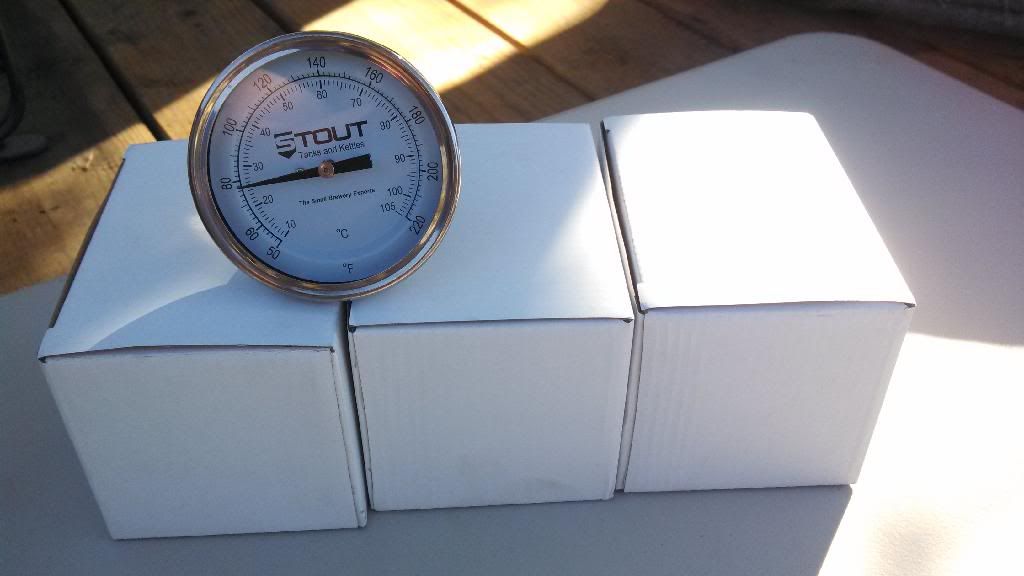

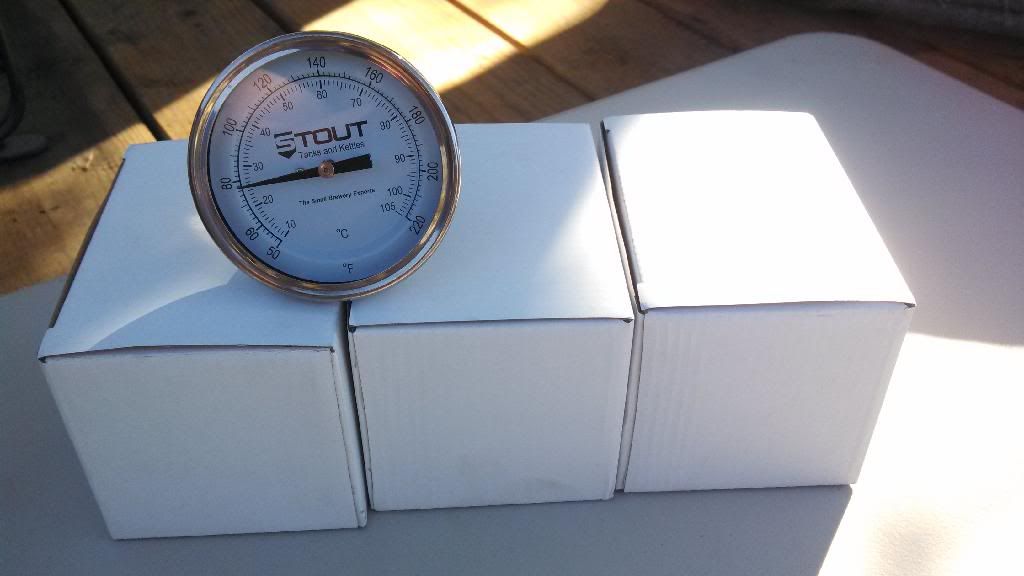

It also came with (3) 1/2" NPT x 3" bi-metal thermometers. Since I am going to control this with a BCS I don't need the temperatures of the vessels. I plan to use these in other places. Likely output of the plate chiller, city water into the plate chiller and another place. I haven't really decided on the last location.

One thing that is odd is this fitting on the back of the HLT. The lower port is for the heating element but I have no idea what the top port is for. Do you guys know? I thought maybe it is a water fill port. It is a 1.5" TC port.

Kettles are made by Stout Tanks and Kettles out of PDX. I shipped them to the local brewery who had a loading dock. This cut my freight in half. I would highly suggest doing something like this if you decide to order from Stout.

Here is what I ordered:

Boil Kettle:

BK30TW-TI-SG-EL1. (2240). 30 Gal. Brew Kettle with (1) 1.5in. TC Port for electric element w/1in. NPS adapter, Thermowell, Tangential Inlet, Sight Glass, (2)3/4in. valves, (2) 1/2in. hose barbs, clamps/gaskets

HLT:

HL30TW-RHC-SG-EL1-XP. (Custom). 30 Gal. Hot Liquor Tank with Thermowell, RAISED HERMS Coil, Sight Glass,(1) Element Port with 1" NSP adapter, (1) Upper Port, (1)3/4in. Valve, (3) 1/2in. Hose Barbs, clamps/gaskets

MLT:

MT30TW-RF-BO (476). 115L Mash Tun with Bottom Outlet, Thermowell, Recirculation Fitting, (1)19mm Valve, (2) 1/2in. Hose Barbs, Clamps/Gaskets

Sparge Arm:

SP12SA. (720). Sparge Arm, 12in. long, with 2 clamps/gaskets, (1) 1.5in. end cap

I will total up all my costs once I get a little bit further in. I will post it up here in this first post.

And on to the pictures!

Here they are in the back of my pickup truck:

First look:

I had questions about the thermowell that it came with. This answered my questions. It is about 3" deep and has 1/2"NPT threads. It is welded in place so inside the kettles it is completely sanitary. I will just need a 1/2"npt x 1/4" compression to hold the temperature probes in place.

This is the sparge arm that came with the setup. It has a bunch of holes in the bottom for fly sparging:

And now for some brew porn. It came with more tri-clamps and gaskets but some were installed on the kettles at the time I took the pictures.

It also came with (3) 1/2" NPT x 3" bi-metal thermometers. Since I am going to control this with a BCS I don't need the temperatures of the vessels. I plan to use these in other places. Likely output of the plate chiller, city water into the plate chiller and another place. I haven't really decided on the last location.

One thing that is odd is this fitting on the back of the HLT. The lower port is for the heating element but I have no idea what the top port is for. Do you guys know? I thought maybe it is a water fill port. It is a 1.5" TC port.