You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

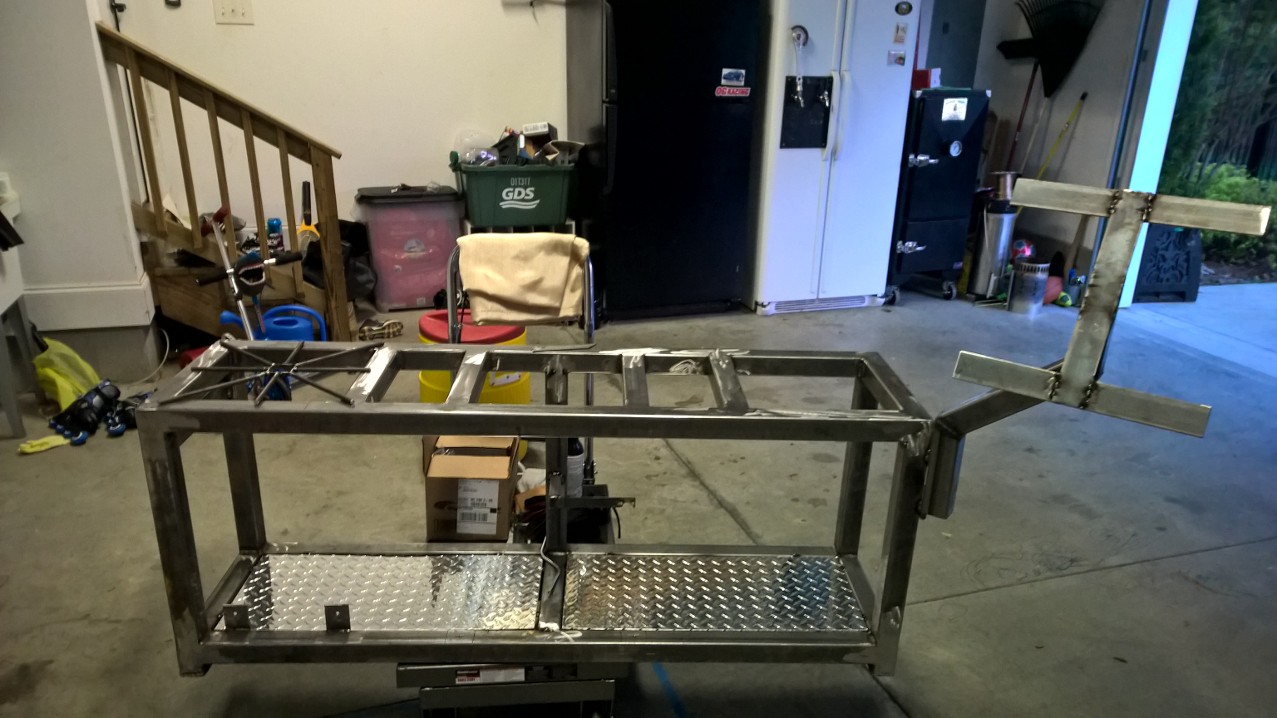

Single tier, automated propane rig

- Thread starter NoH20

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

sandyeggoxj

Well-Known Member

Looking good so far todd!

- Joined

- Jun 12, 2014

- Messages

- 574

- Reaction score

- 191

Looks great. Love the kart in the background

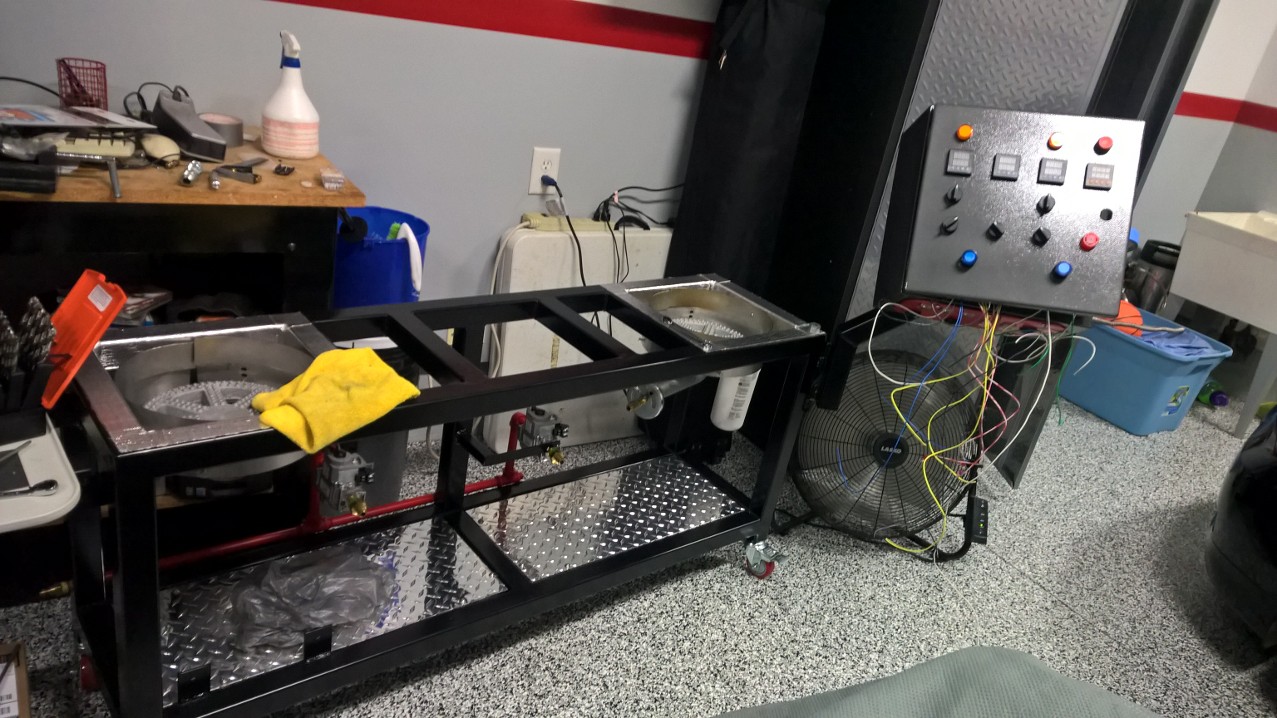

Oh how life gets in the way!! Anyway, making progress. Stand is back from powder coat (where it sat for almost 4 weeks :-( ) as of this morning. Now it's time for reassembly. I have made some progress on the control panel, and it's starting to make some sense to me at this point.

Todd

Todd

Stealthcruiser

Well-Known Member

^ ^ ^ ^ ^.........Under the wraps.........356 or 911?

Getting even closer yet. Tested heating up the water to see how the burner(s) performed. Seems ok, ~ 3.25 degrees/minute. No icing of tank, etc. Good blue flame. I have about 3 inches from top of burner to bottom of kettle. Think I'll leave it there. I can go up in .5 inch increments.

Sadly, it doesn't look like the powder coat will survive around the burners. Sorta figured. Guy that did the stand said he would strip it for free and ceramic coat it for 1/2 price.

Todd

Sadly, it doesn't look like the powder coat will survive around the burners. Sorta figured. Guy that did the stand said he would strip it for free and ceramic coat it for 1/2 price.

Todd

- Joined

- Jun 12, 2014

- Messages

- 574

- Reaction score

- 191

Getting even closer yet. Tested heating up the water to see how the burner(s) performed. Seems ok, ~ 3.25 degrees/minute. No icing of tank, etc. Good blue flame. I have about 3 inches from top of burner to bottom of kettle. Think I'll leave it there. I can go up in .5 inch increments.

Sadly, it doesn't look like the powder coat will survive around the burners. Sorta figured. Guy that did the stand said he would strip it for free and ceramic coat it for 1/2 price.

Todd

Wouldn't ceramic coating crack due to temperature differential between the hot and cool part of the stand?

That I don't know. I think it will be a gradual change in temp as areas near the burner are also warm-to-hot (depending on how close). Not sure if ceramic would even hold up, but it should be better than powder coat (which I think bakes at around 400).

Burner is putting out a great deal of heat. And this is on low pressure LP.

Todd

Burner is putting out a great deal of heat. And this is on low pressure LP.

Todd

BeardedBrews

Well-Known Member

Did you go 3x 20g on all three Stout Tanks, or is that a 15g Mash Tun?

I either got the enclosure from Amazon or ebay (thinking Amazon). There were several different sizes. Was around $80 I think. A whole punch made life pretty easy (all the switches and lights are the same size... PIDS are a little more trouble to cut out).

Todd

Todd

Lgaddy44

Well-Known Member

Very nice. I may need to bounce some questions off you later, if you don't mind. I'm building something similar, and haven't quite ran through the specifics on wiring and gas plumbing yet. I might get to that point in a couple weeks though.

Absolutely, let me know. Unfortunately the site seems to send emails.about once a week when there is a reply to something you've posted, so I've been bad about responding.

It's up and running now, so let me know what your questions are. (btw-certainly didn't reinvent the wheel, just learned from other folks on this site.)

Todd

It's up and running now, so let me know what your questions are. (btw-certainly didn't reinvent the wheel, just learned from other folks on this site.)

Todd

You got a beautiful build going there! Good luck brewing on your creation!

John

John

carpediem1230

New Member

- Joined

- Sep 14, 2015

- Messages

- 4

- Reaction score

- 0

Very nice. What's the fabric like piece that you have on the stand near the burners?

Similar threads

- Replies

- 1

- Views

- 570

- Replies

- 0

- Views

- 608

- Replies

- 1

- Views

- 496

- Replies

- 0

- Views

- 748

- Replies

- 2

- Views

- 705