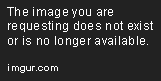

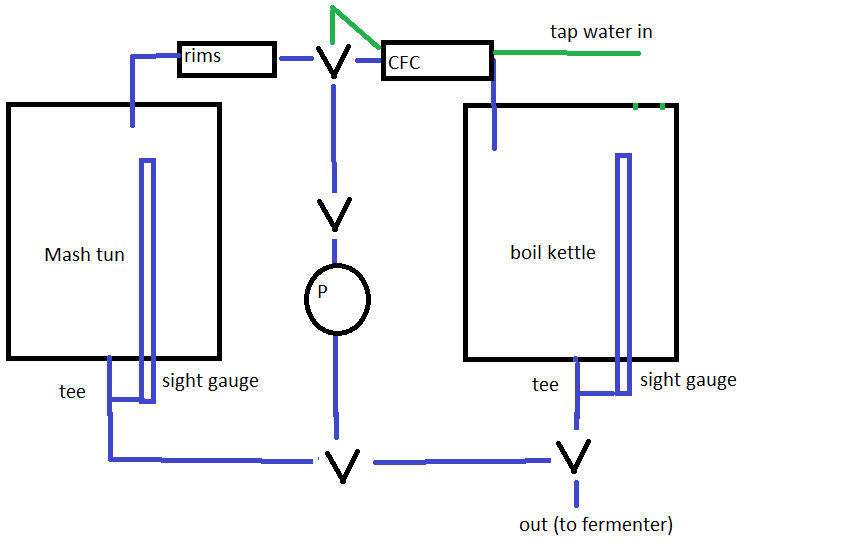

I've been pondering to coming up with a new brew system and stand and was hoping to get some feedback from you guys on the attached configuration. This is drawing #3 and easily the simplest of the bunch (and simplest from those I've seen around hbt).

Is it a bad idea to put the CFC and RIMS tube in series?

Please give me your thoughts, suggestions, concerns, etc... this seems too simple.

One concern I had was that there would be ~30' of 1/2" line from pump to either vessel because of the cfc, don't know if that would cause any problems. I'm hoping that with the bottom drain like it is that it would siphon any wort out of the lines as it drains, that sound reasonable?

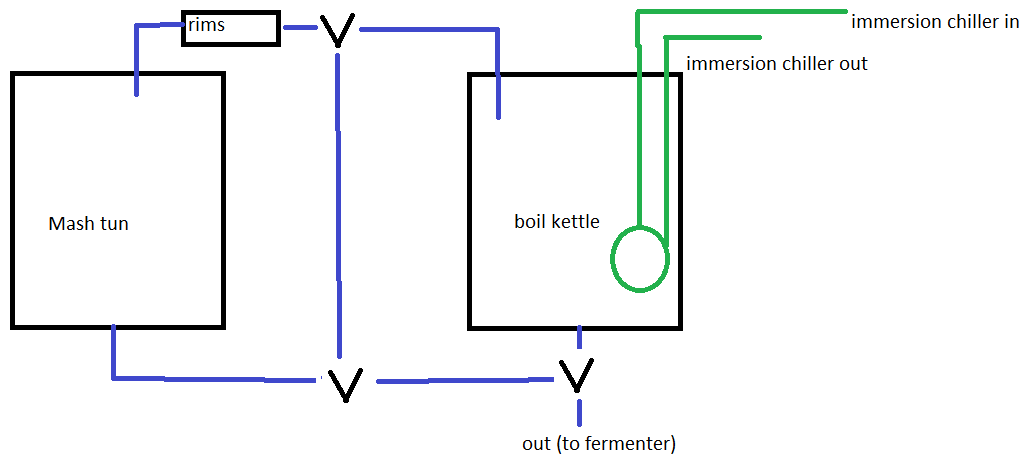

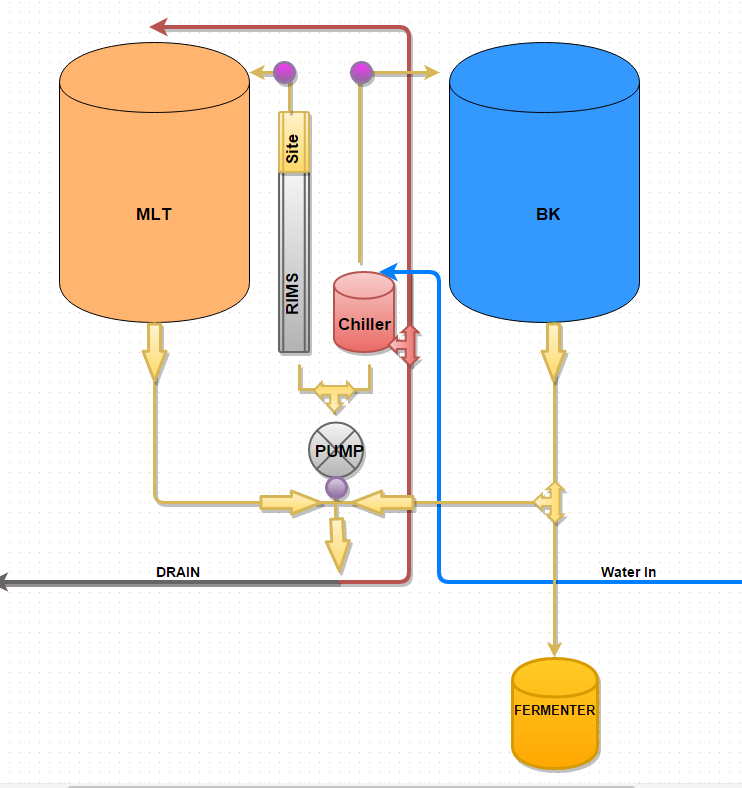

Proposed CFC:

Is it a bad idea to put the CFC and RIMS tube in series?

Please give me your thoughts, suggestions, concerns, etc... this seems too simple.

One concern I had was that there would be ~30' of 1/2" line from pump to either vessel because of the cfc, don't know if that would cause any problems. I'm hoping that with the bottom drain like it is that it would siphon any wort out of the lines as it drains, that sound reasonable?

Proposed CFC: