Ok - so I saw the post by PlinyTheMiddleAged and that was all I needed to get my latest project off the ground.

For over a year now I have been envisioning a way to do this with ball jar and the proper lid - he found them and away I go now.

Holy Shiznit - getting all the parts for this thing was expensive!

I just spent around $130 for:

3 Wide-Mouth Jar Bands (Rings)) Item Price: $11.95

6 x Tank Post & Dip Tube Nipple - Weld-in-Place - Stainless Steel (TankNipple-WIP 15C07103ih) $26.58

3 x Cornelius & AEB - Spartan - Super Champion. Gas IN (TankPlug-CorneliusGAS-15C07115IH) $29.55

3 x Cornelius & AEB - Spartan - Super Champion. Liquid OUT (TankPlug-CorneliusLIQ-15C07116IH) $29.55

3 x Diptube - Liq out - Firestone/Spartan Straight (DiptubeStrght-5gal - 15C07129IH) $33.75

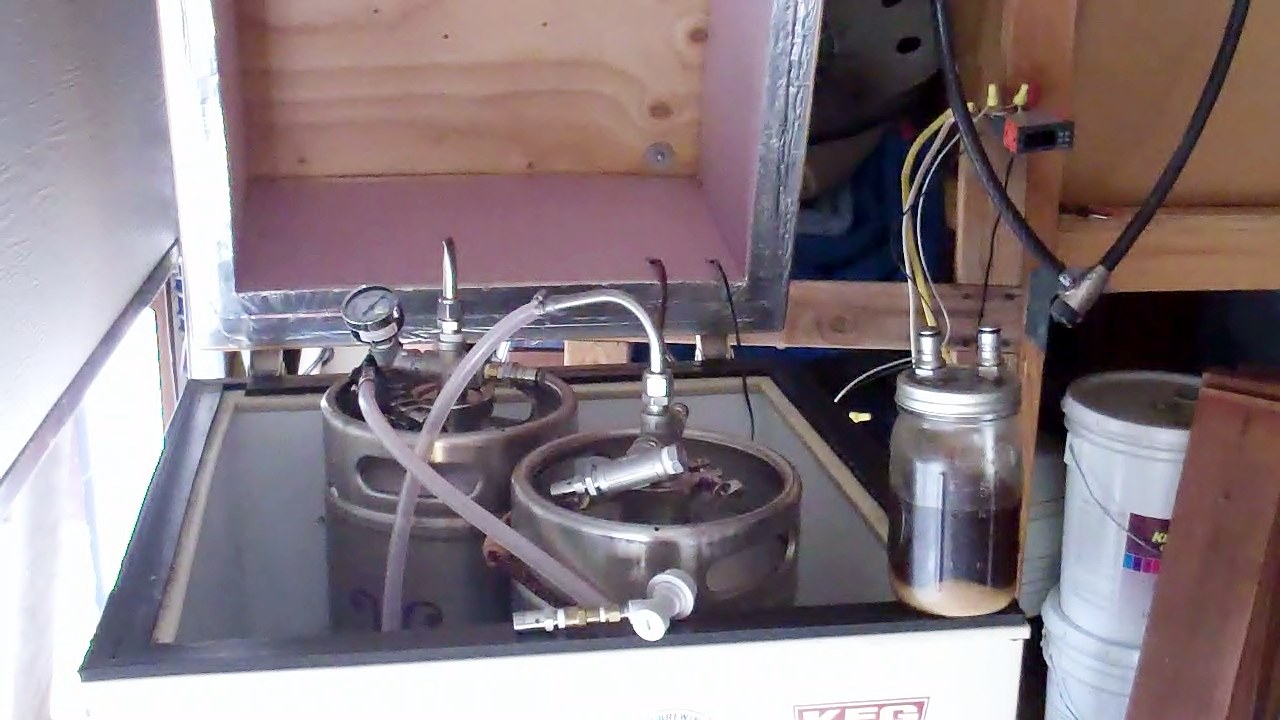

My idea is to have a corny disconnect post attached twice on each lid one gas one line w/ diptube - then attach my line tube from the fermenter into the liquid side of this lid into a half gallon ball jar and use a pressure release gauge from morebeer that I use during transfers on the gas side to take the o2 out of the jar and prevent the exploding jar trick.

I will use this method after one day of waiting for the temps to be just right before I pitch and then I will take out as much trub as I can (and of course a little wort too =:<) and I then pitch the yeast in my 13.2g sanke (10g batch).

After the cold crash I will take out the yeast via the same method before I transfer the beer to the serving keg . This method should be great! Thank you for finding these lids PlinyTheMiddleAged!! Yeast transfer w/ no o2 and no mess now!!!

For over a year now I have been envisioning a way to do this with ball jar and the proper lid - he found them and away I go now.

Holy Shiznit - getting all the parts for this thing was expensive!

I just spent around $130 for:

3 Wide-Mouth Jar Bands (Rings)) Item Price: $11.95

6 x Tank Post & Dip Tube Nipple - Weld-in-Place - Stainless Steel (TankNipple-WIP 15C07103ih) $26.58

3 x Cornelius & AEB - Spartan - Super Champion. Gas IN (TankPlug-CorneliusGAS-15C07115IH) $29.55

3 x Cornelius & AEB - Spartan - Super Champion. Liquid OUT (TankPlug-CorneliusLIQ-15C07116IH) $29.55

3 x Diptube - Liq out - Firestone/Spartan Straight (DiptubeStrght-5gal - 15C07129IH) $33.75

My idea is to have a corny disconnect post attached twice on each lid one gas one line w/ diptube - then attach my line tube from the fermenter into the liquid side of this lid into a half gallon ball jar and use a pressure release gauge from morebeer that I use during transfers on the gas side to take the o2 out of the jar and prevent the exploding jar trick.

I will use this method after one day of waiting for the temps to be just right before I pitch and then I will take out as much trub as I can (and of course a little wort too =:<) and I then pitch the yeast in my 13.2g sanke (10g batch).

After the cold crash I will take out the yeast via the same method before I transfer the beer to the serving keg . This method should be great! Thank you for finding these lids PlinyTheMiddleAged!! Yeast transfer w/ no o2 and no mess now!!!