- Joined

- Dec 17, 2012

- Messages

- 144

- Reaction score

- 18

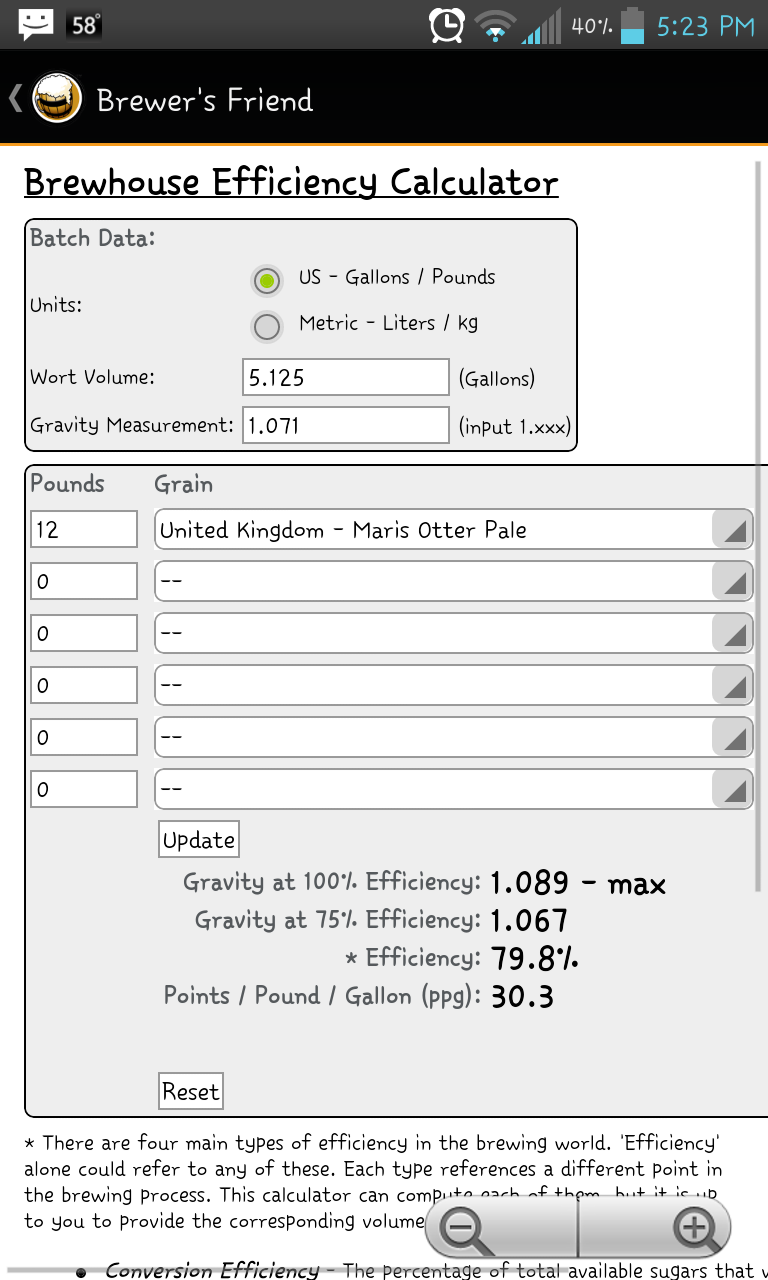

Recently made the switch to the BIAB method. I have done 3 brews and did each one with some variation in the method to see for myself the outcome. Maybe others getting started in this method will find this useful as they determine their own methods. All calculations are based on Brewers Friend software.

Beer 1: 60 min mash @ 152F, full water volume mash, minimal mash stir, heated to 170F for mash out, squeezed draining bag like I was mad at it. Got 58% efficiency.

Beer 2: 60 min mash @ 152F, 6 gallon partial water mash, minimal mash stir, no mash out. Rinsed/sparged draining grain bag with about 2 gallons of 170F water. No squeeze. Got 60% efficiency.

Beer 3: 70 min mash @ 152F (90 min was target but I got bored), full water volume mash, brisk stir with 24" whisk every 20 minutes. No mash out. Let bag drain for 20 minutes while heating for boil, no squeeze. Got 66% efficiency.

All three brews had a single pass grain milling at my LHBS.

I am not one to chase every point of efficiency I can get, but do hope to be consistent so recipe's can be adjusted accordingly. I believe the vigorous stirs in method 3 made the most difference for me in getting better efficiency. A double milling or finer grain crush likely would help, will consider trying this variation in the future.

Not trying to stump for any method with this post, just sharing personal results that might be of use to someone else just getting into the BIAB method to consider trying. I am a big fan of the BIAB method. I like easy.

Beer 1: 60 min mash @ 152F, full water volume mash, minimal mash stir, heated to 170F for mash out, squeezed draining bag like I was mad at it. Got 58% efficiency.

Beer 2: 60 min mash @ 152F, 6 gallon partial water mash, minimal mash stir, no mash out. Rinsed/sparged draining grain bag with about 2 gallons of 170F water. No squeeze. Got 60% efficiency.

Beer 3: 70 min mash @ 152F (90 min was target but I got bored), full water volume mash, brisk stir with 24" whisk every 20 minutes. No mash out. Let bag drain for 20 minutes while heating for boil, no squeeze. Got 66% efficiency.

All three brews had a single pass grain milling at my LHBS.

I am not one to chase every point of efficiency I can get, but do hope to be consistent so recipe's can be adjusted accordingly. I believe the vigorous stirs in method 3 made the most difference for me in getting better efficiency. A double milling or finer grain crush likely would help, will consider trying this variation in the future.

Not trying to stump for any method with this post, just sharing personal results that might be of use to someone else just getting into the BIAB method to consider trying. I am a big fan of the BIAB method. I like easy.