I have a beer to force carbonate this week. Have searched and read many threads but I am still very confused. I found this post from Nicegirl that seems to make a lot of sense: https://www.homebrewtalk.com/forum/threads/forced-carbonation-using-a-carbonation-stone.469875/

My LHBS told me to use a different but simpler process but I have doubts.

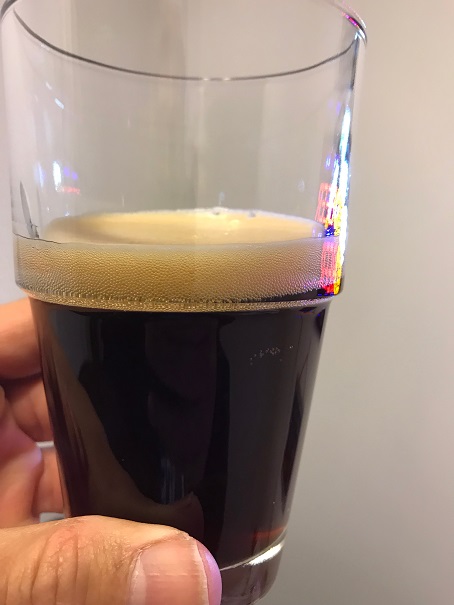

I have of course keg and carbonation lid with stone. This is a brown ale (Bells Best Brown copy) with around 6% ABV. Beer in keezer now should be at around 34°-36°F. I am referencing this carbonation table: http://www.brewandgrow.com/brew/media/pdf/Carbonation-Stone-Instructions.pdf

Could you please help me decide which of these two processes below should I use??

Nicegirl Process Steps:

1. Transfer beer from Carboy to cold 5gal keg

2. Connect gas line to keg gas input

3. Purge top of keg with CO2

4. Connect gas line to carbonation stone port at carb lid

- Using final pressure of 10.2 + wetting pressure, let say 14.2psi assuming 4psi wetting pressure (2.5 CO2 vol: per table linked above and for beer style and beer aprox temp in keezer mentioned above)

6. Set pressure to 6psi and wait 30min

7. Set pressure to 8psi and wait 30min

8. Set pressure to 10psi and wait 30min

9. Set pressure to 12psi and wait 30min

10. Set pressure to 14.2psi and leave it for 48hrs

11. Set pressure back to serving pressure (10-12psi) and test pour beer.

LHBS Process Steps:

1. Transfer beer from Carboy to cold 5gal keg

2. Connect gas line to keg gas input

3. Purge top of keg with CO2

4. Connect gas line to carbonation stone port at carb lid

5. Set pressure to 30psi and shake keg (somehow inside keezer?) about 80 times

6. Wait one hour

7. Set pressure back to serving pressure (10-12psi) and pour test beer.

My LHBS told me to use a different but simpler process but I have doubts.

I have of course keg and carbonation lid with stone. This is a brown ale (Bells Best Brown copy) with around 6% ABV. Beer in keezer now should be at around 34°-36°F. I am referencing this carbonation table: http://www.brewandgrow.com/brew/media/pdf/Carbonation-Stone-Instructions.pdf

Could you please help me decide which of these two processes below should I use??

Nicegirl Process Steps:

1. Transfer beer from Carboy to cold 5gal keg

2. Connect gas line to keg gas input

3. Purge top of keg with CO2

4. Connect gas line to carbonation stone port at carb lid

- Using final pressure of 10.2 + wetting pressure, let say 14.2psi assuming 4psi wetting pressure (2.5 CO2 vol: per table linked above and for beer style and beer aprox temp in keezer mentioned above)

6. Set pressure to 6psi and wait 30min

7. Set pressure to 8psi and wait 30min

8. Set pressure to 10psi and wait 30min

9. Set pressure to 12psi and wait 30min

10. Set pressure to 14.2psi and leave it for 48hrs

11. Set pressure back to serving pressure (10-12psi) and test pour beer.

LHBS Process Steps:

1. Transfer beer from Carboy to cold 5gal keg

2. Connect gas line to keg gas input

3. Purge top of keg with CO2

4. Connect gas line to carbonation stone port at carb lid

5. Set pressure to 30psi and shake keg (somehow inside keezer?) about 80 times

6. Wait one hour

7. Set pressure back to serving pressure (10-12psi) and pour test beer.