@Rob2010SS

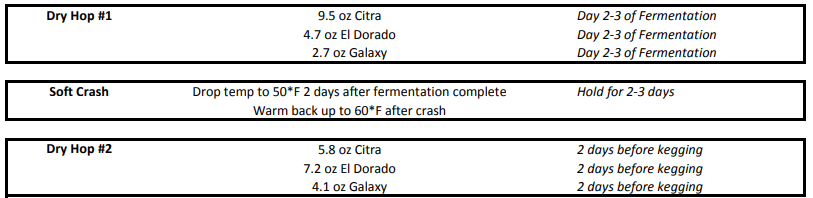

What are you fermenting in? Bagging the dry hops and adding them in two separate additions is a sure fire way to add a bunch of O2 which will pretty much negate all those hops you’re adding. Don’t add hops during fermentation, especially a lot of them.

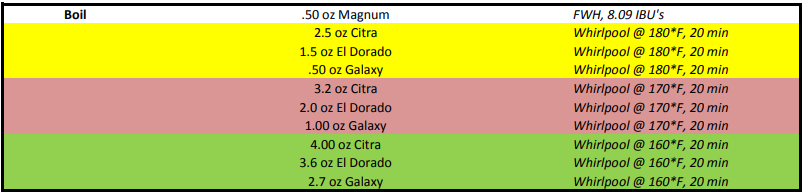

In regards to WP hopping... I think this is the place where you find the biggest difference between what homebrewers will tell you and what professionals will tell you. Personally I think homebrewers obsess over whirlpool temps/timing/and amounts waaaaaay too much.

How many of you test your gravity samples before dry hopping? How often by the end of fermentation are you like wow I can really pick out that huge addition of hop X? So often they always just taste the same to me. Yes there are some hops that come through fermentation better than others but for the most part it seems like so much of what’s added hotside just gets lost and especially when you’re going to be adding a huge dry hop load on top.

Recent podcast with Noah Bissell and Scott Janish where Janish says at Sapwood they’re adding 2#/bbl in the WP at temps around 180. Noah’s reaction is pretty funny. Said he doesn’t know anyone that goes that high. Another podcast with Noah recently where he discussed trading recipes with JC and they made each other’s signature pale ales. Trillium made Substance and Bissell made Fort Point. Noah had to call JC cause he thought the recipe was wrong as there were so few hotside hops in Fort Point.

My advice would be:

Pick a whirlpool temp and add them all there. 180 is generally what I choose. Whirlpool for 10, let settle and start chilling.

I think going over .5-.75oz/gallon is really not worth it. I just don’t think the hops come through fermentation well enough to justify adding more honestly. This also depends on yeast, ferm temp, pitch rate.

Are you using a conical? 15gallon batch right? How are you keeping O2 at bay? What are your pH targets?