SavageBrewer

Well-Known Member

- Joined

- Jun 20, 2012

- Messages

- 56

- Reaction score

- 7

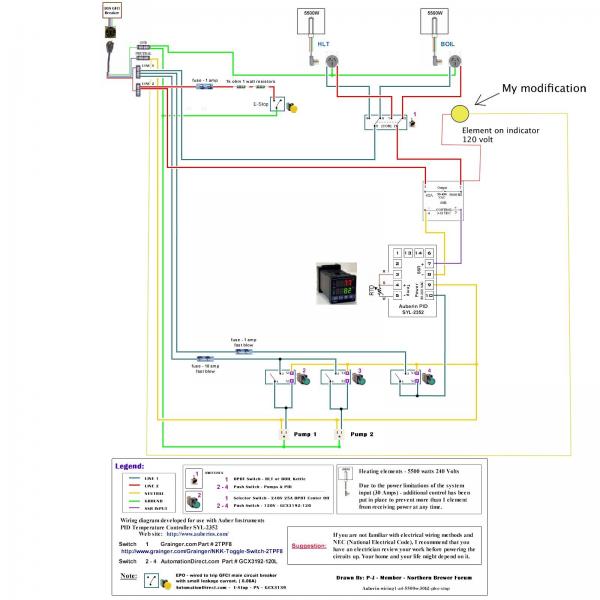

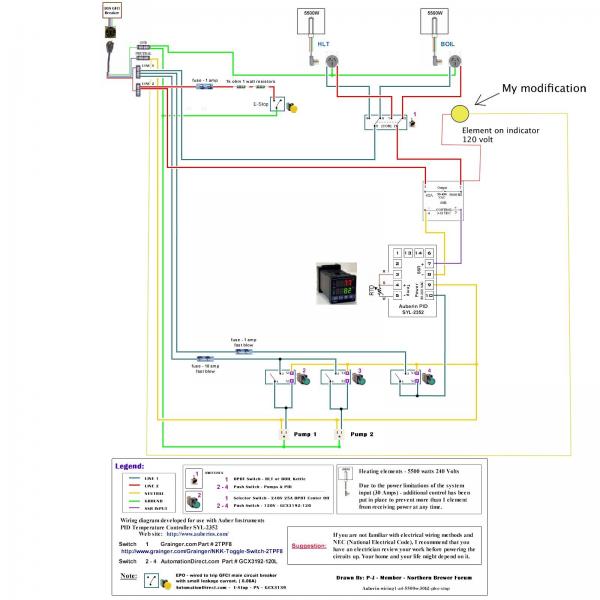

I am building a E HERMS system using one of the schematics from P-J. I am having a problem with the element on indicator staying on. When the PID is not turning on the element the LED is dim. When the element is turned on the LED gets brighter. I think this might be a problem brewing on a bright day outside, being that it would be hard to tell if the element is on. Here is the schematic I am using and have added an indicator in it. Please help me understand if I am doing anything wrong. Thank you.