HopDevil7

Member

Hi all. Long time reader, first time poster.

Background:

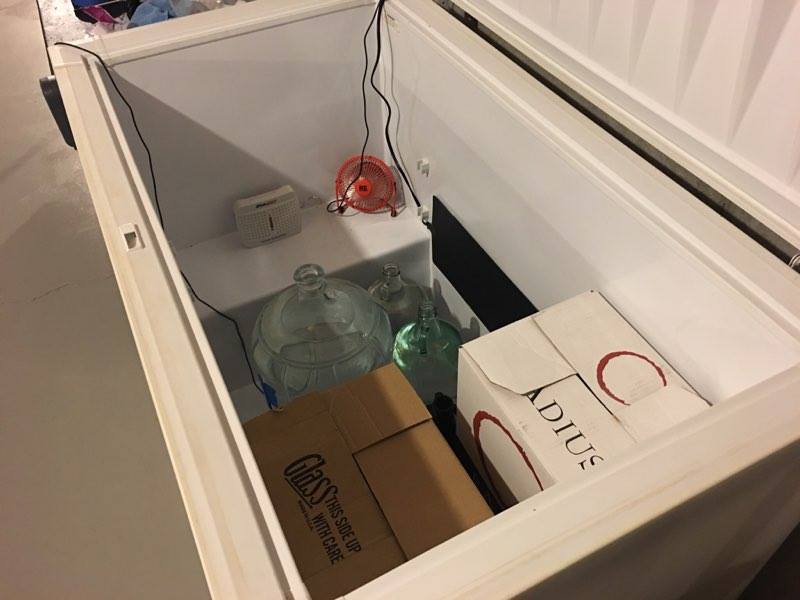

I recently purchased a chest freezer off craigslist to use as a fermentation chamber. This time of year in PA, my basement temperature is ~59-60 degrees (F). My goal is to stabilize a temperature ~68F. I purchased an inkbird and a thermowell which is submerged in a one gallon carboy set inside the chest freezer (please see attached pictures).

Issue: I cannot stabilize/control the temperature for the life of me. I have 2 degrees differential set both ways (heat/cool) and the heater turns off when the initial goal of 68 degrees is achieved. Then, it approaches 70 degrees (no heat/cool source activated) so the chest freezer turns on, gets up to 71-72 degrees and then begins to drop sharply to 65-66 degrees triggering the heat source to turn on. Repeat.. on/off/on/off etc.

Equipment I am using:

Temperature Controller: Inkbird Itc-308

https://www.amazon.com/dp/B011296704/?tag=skimlinks_replacement-20

Cooling Source: ~14.6 cubic feet Gibson Chest Freezer

Heat Source: Lasko #100 MyHeat Personal Ceramic Heater (200 watt)

https://www.amazon.com/dp/B003XDTWN2/?tag=skimlinks_replacement-20

Question: What can I do to get this thing stabilized before using for brewing? My initial thought is that my tiny space heater (200 watt) is still too powerful causing the water temp to rise another ~3 degrees after the 68 degree temp is reached (thus causing subsequent heat/cool/heat/cool cycles)

Background:

I recently purchased a chest freezer off craigslist to use as a fermentation chamber. This time of year in PA, my basement temperature is ~59-60 degrees (F). My goal is to stabilize a temperature ~68F. I purchased an inkbird and a thermowell which is submerged in a one gallon carboy set inside the chest freezer (please see attached pictures).

Issue: I cannot stabilize/control the temperature for the life of me. I have 2 degrees differential set both ways (heat/cool) and the heater turns off when the initial goal of 68 degrees is achieved. Then, it approaches 70 degrees (no heat/cool source activated) so the chest freezer turns on, gets up to 71-72 degrees and then begins to drop sharply to 65-66 degrees triggering the heat source to turn on. Repeat.. on/off/on/off etc.

Equipment I am using:

Temperature Controller: Inkbird Itc-308

https://www.amazon.com/dp/B011296704/?tag=skimlinks_replacement-20

Cooling Source: ~14.6 cubic feet Gibson Chest Freezer

Heat Source: Lasko #100 MyHeat Personal Ceramic Heater (200 watt)

https://www.amazon.com/dp/B003XDTWN2/?tag=skimlinks_replacement-20

Question: What can I do to get this thing stabilized before using for brewing? My initial thought is that my tiny space heater (200 watt) is still too powerful causing the water temp to rise another ~3 degrees after the 68 degree temp is reached (thus causing subsequent heat/cool/heat/cool cycles)

Last edited by a moderator: