Jthornburgh

Well-Known Member

- Joined

- Oct 1, 2015

- Messages

- 87

- Reaction score

- 9

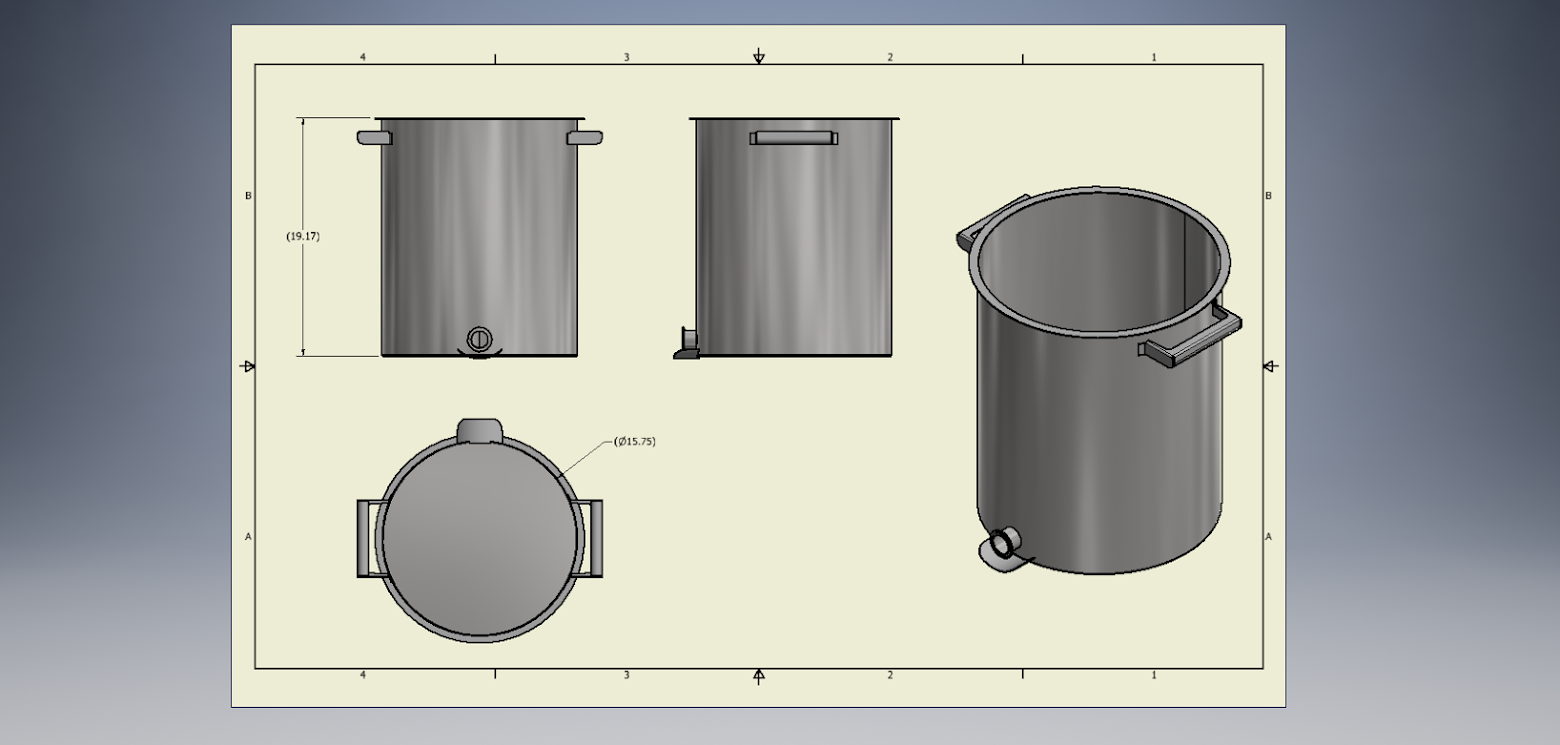

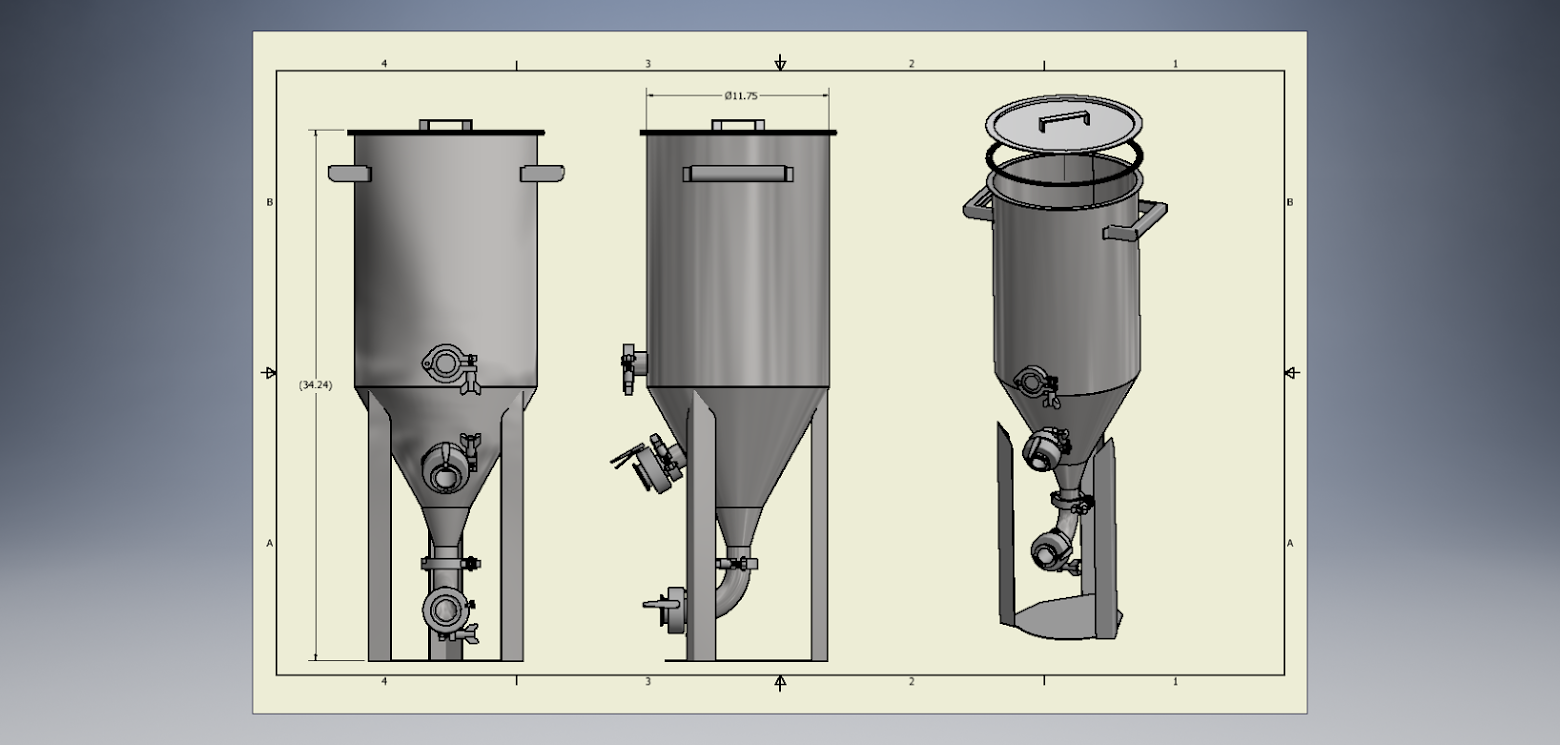

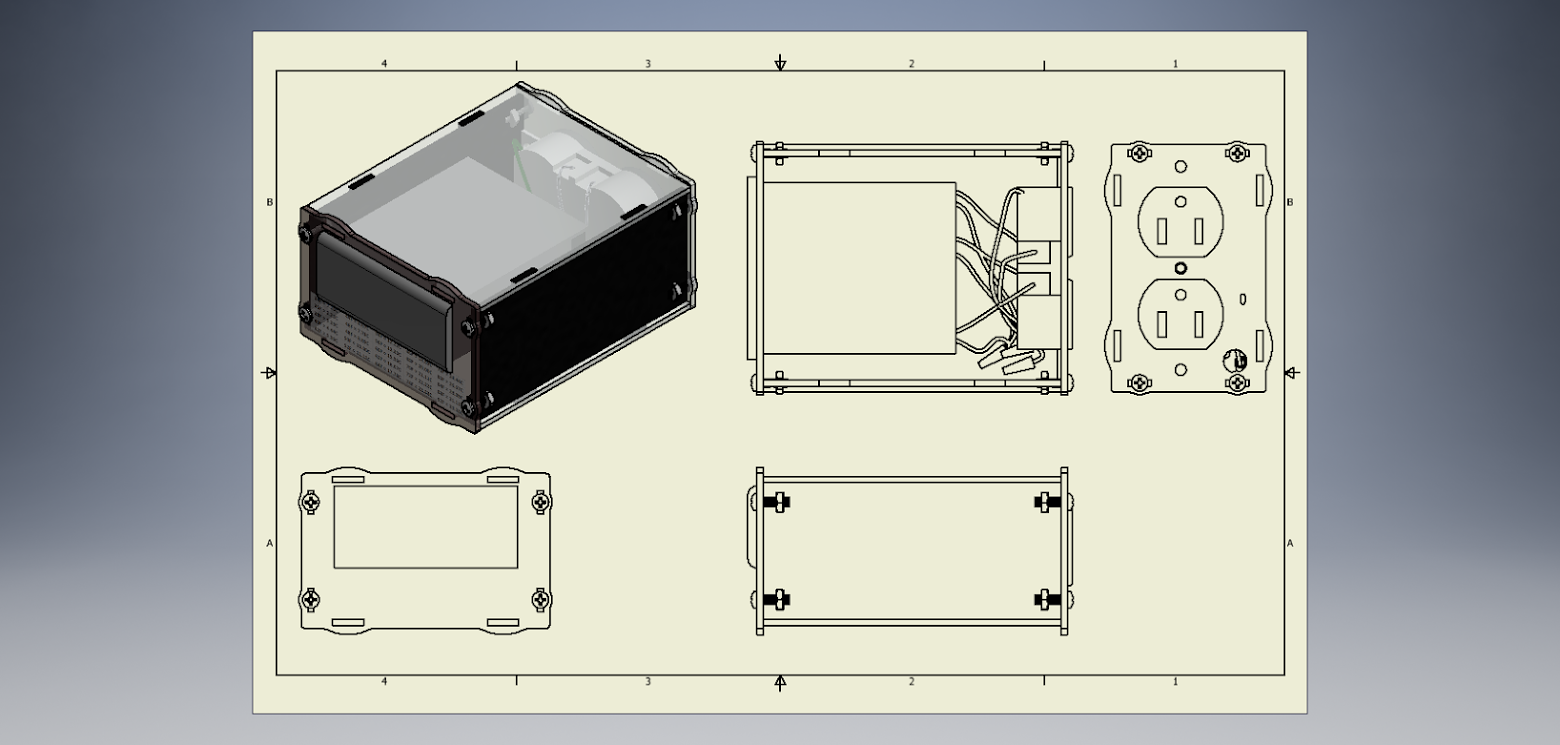

I have spent quite a lot of time wanting to start brewing. When I got serious, I wanted to make sure that I would have everything that I needed, not just to make great beer, but also to make the process go smoothly. I went through many threads here, as well as all over the web looking for what people wish they had done differently, or common problems. I took all of this into account and fully designed my system online before buying anything. This included deciding to build my own Boil Kettle and Conical Fermenter.

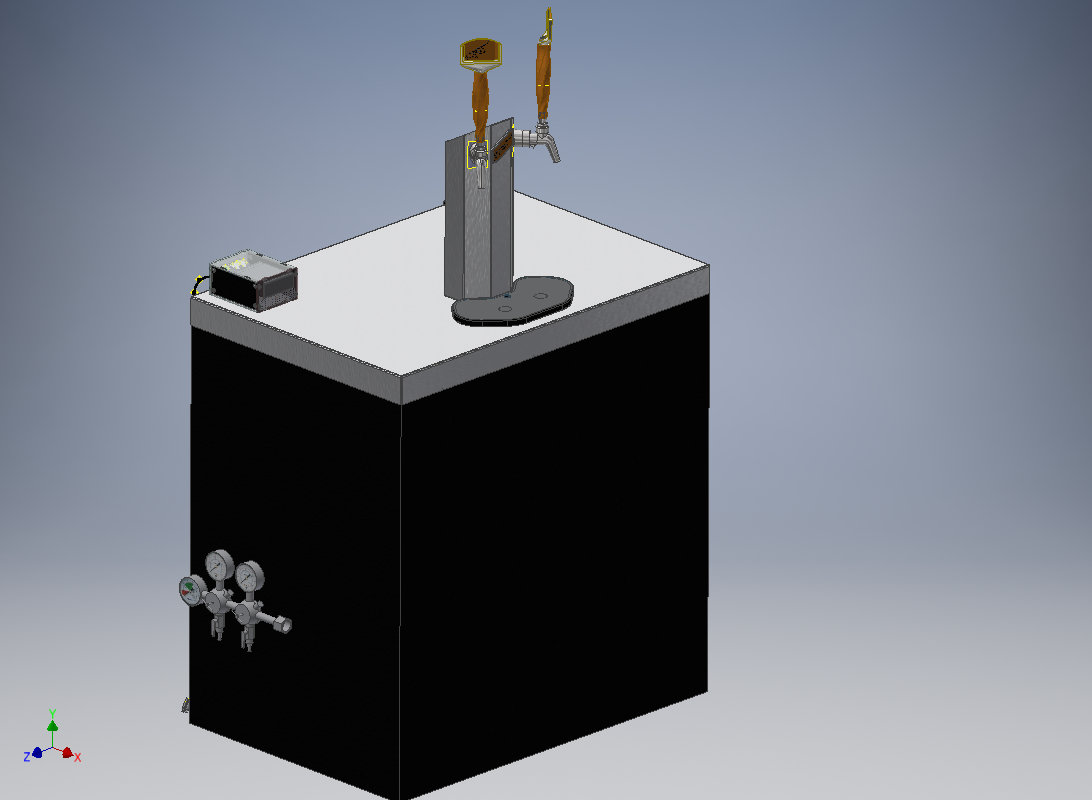

I planned on turning a chest freezer that I already had into the keezer, and during the design phase, had an upright freezer given to me that would turn into the fermentation chamber.

So I ordered everything, and started working on making the Kettle and Fermentor.

The day after I cut everything out, I found someone selling an entire setup, including a 7.3 Gallon Stout Conical.

Now to the system Pictures.

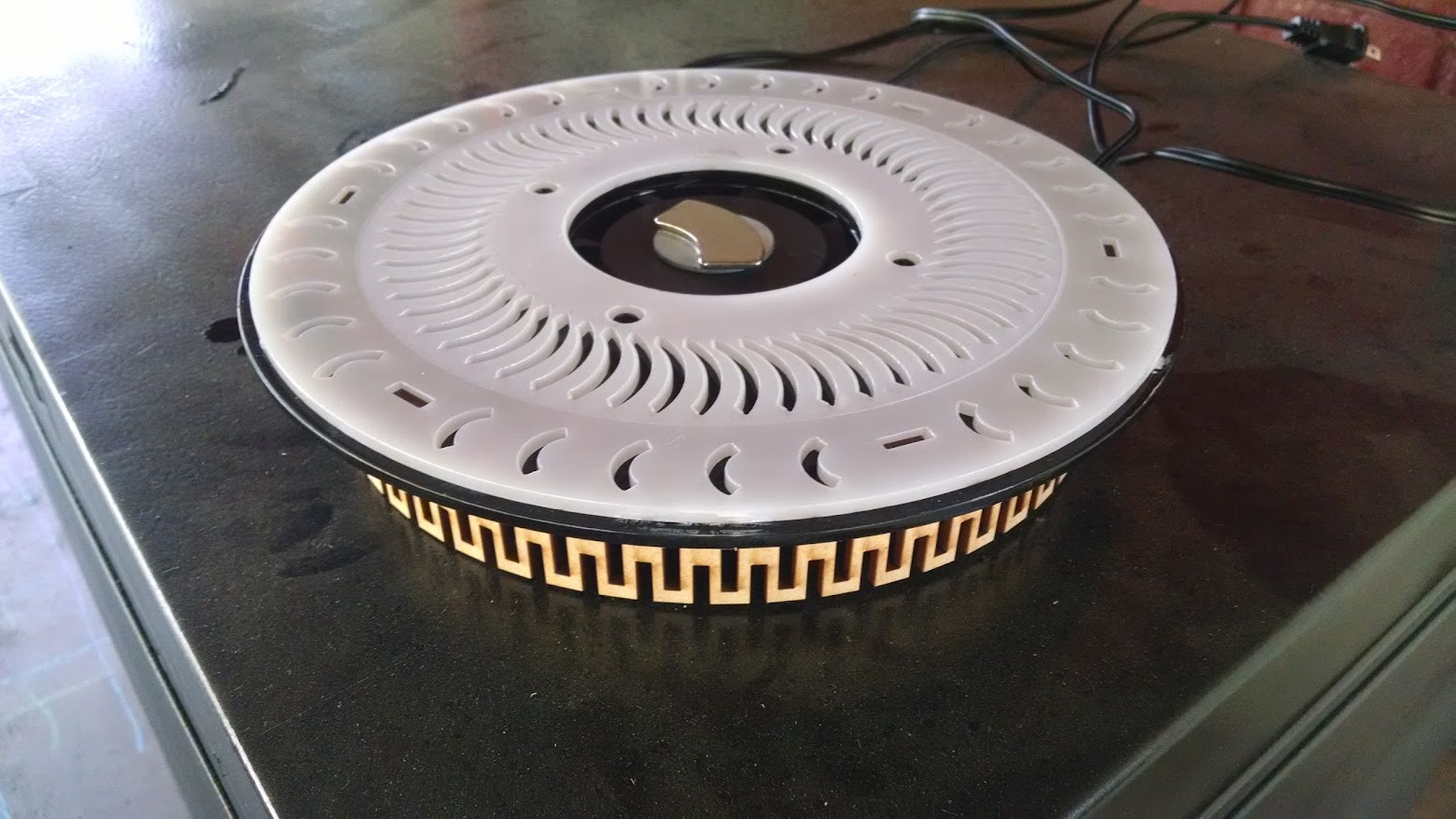

Stir Plate:

Mash:

Chilling Process:

Today I made a Whirlpool arm, I didn't include one in the Kettle because I wanted to be able to move it around.

Transferring to Fermentor:

In the Chamber:

Keezer

I planned on turning a chest freezer that I already had into the keezer, and during the design phase, had an upright freezer given to me that would turn into the fermentation chamber.

So I ordered everything, and started working on making the Kettle and Fermentor.

The day after I cut everything out, I found someone selling an entire setup, including a 7.3 Gallon Stout Conical.

Now to the system Pictures.

Stir Plate:

Mash:

Chilling Process:

Today I made a Whirlpool arm, I didn't include one in the Kettle because I wanted to be able to move it around.

Transferring to Fermentor:

In the Chamber:

Keezer