Hey Gang,

Looking to change my brew setup, and I think I've settled on a 2-vessel RIMS system. I believe I've finalized my requirements for what I want out of it, so now I'm looking for some feedback on how best to enable this. Here is what I desire out of the system:

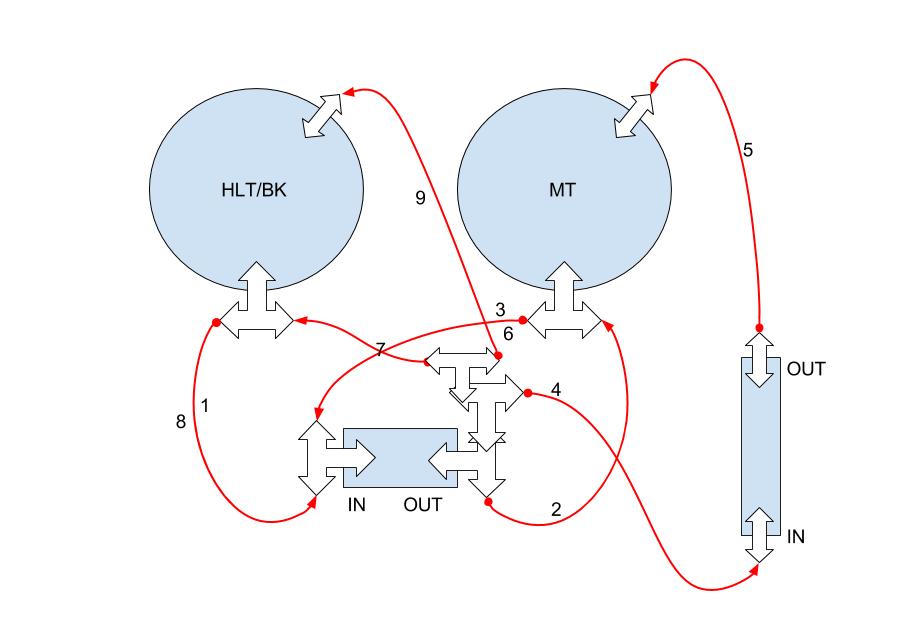

So based on all of that I'm thinking I need to go with something like:

If anyone could offer any advice or feedback before I go running off to buy parts I would greatly appreciate it. If you have a setup like this and wouldn't mind showing off some pictures, I would appreciate that too!

Looking to change my brew setup, and I think I've settled on a 2-vessel RIMS system. I believe I've finalized my requirements for what I want out of it, so now I'm looking for some feedback on how best to enable this. Here is what I desire out of the system:

- I want to do 5 gallon batches of things up to a SG of 1.1 or slightly higher

- I want to do no-sparge, so full volume mash in a single infusion

- I want to use gas to heat the strike water and do the boil and 110V RIMS to control mash temp and recirculate for the entire mash

- I would like the ability to raise the mash temp up to 168 or so to mash out

- I don't want to have to move hoses around during the entire brewing process (I'm okay changing hoses to drain to the fermenter)

- I would love to continue to use my immersion chiller with whirlpool arm, but could be convinced to go with a CFC but am concerned with clogging as I use hop pellets and don't bag them

So based on all of that I'm thinking I need to go with something like:

- 2 - 16 Gallon Vessels (1 that's a dual purpose HLT/BK and 1 that's dedicated to the MT)

- Each vessel with a 3-way ball valve attached to the primary port

- Secondary port added to MT for recirculation

- 2 Pumps (would love to do this with 1 - but not sure if it's possible)

- RIMS tube setup

- Simple RIMS controller with 1 PID and 2 pump switches

If anyone could offer any advice or feedback before I go running off to buy parts I would greatly appreciate it. If you have a setup like this and wouldn't mind showing off some pictures, I would appreciate that too!