You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

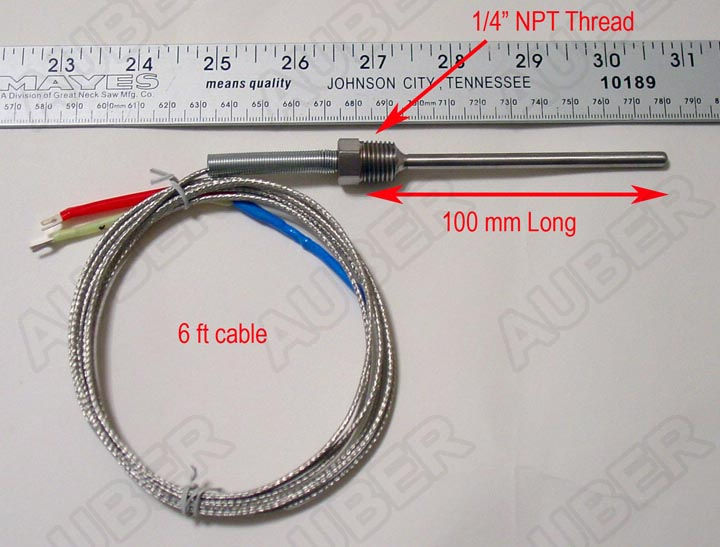

K Type Thermocoupler +/-

- Thread starter Culln5

- Start date

Help Support Homebrew Talk - Beer, Wine, Mead, & Cider Brewing Discussion Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Jul 30, 2014

- Messages

- 56

- Reaction score

- 29

Take a look here: http://www.omega.com/toc_asp/frameset.html?book=Temperature&file=TC_GEN_SPECS_REF

Yellow +

Red -

Yellow +

Red -

From the manual for the SYL-2352 (may not be the PID you are using):

3.1.1 Thermocouple

The thermocouple should be connected to terminals 4 and 5. Make sure that

the polarity is correct. There are two commonly used color codes for the K type

thermocouple. US color code uses yellow (positive) and green/blue (negative). The

temperature reading will decrease as temperature increases if the connection

is reversed.

SO no danger is hooking it up wrong.

3.1.1 Thermocouple

The thermocouple should be connected to terminals 4 and 5. Make sure that

the polarity is correct. There are two commonly used color codes for the K type

thermocouple. US color code uses yellow (positive) and green/blue (negative). The

temperature reading will decrease as temperature increases if the connection

is reversed.

SO no danger is hooking it up wrong.

No. Just be sure it is the same wire for both pins.

FYI, the wire color represents the type of material it is made of. Polarity is determined by the 2 wire types used, so you need to look up the type to know the polarity.

Regarding what wire to use for connections, it really does matter, but it's been a long time since I looked at the details. Basically any 2 dissimilar metals in solid contact will form a thermocouple of some sort, and with Tc's putting out only millivolts other connections can skew your results. If you temperature compensate your control at a specific point related to the operation, then any other factors are minimal as long as those connection points remain at a stable temperature.

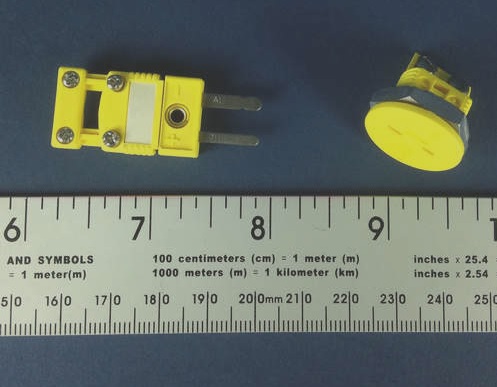

Even the Tc plugs shown come in different types matched to the Tc's, just for this reason.

Regarding what wire to use for connections, it really does matter, but it's been a long time since I looked at the details. Basically any 2 dissimilar metals in solid contact will form a thermocouple of some sort, and with Tc's putting out only millivolts other connections can skew your results. If you temperature compensate your control at a specific point related to the operation, then any other factors are minimal as long as those connection points remain at a stable temperature.

Even the Tc plugs shown come in different types matched to the Tc's, just for this reason.

Actually it doesn't (with one caveat) and here's why. A lot of people think it is the junction of the dissimilar metals that is the basis for the voltage the thermocouple develops but it isn't. It is that if one end of a wire is at one temperature and the other at another there will be a difference in electrical potential between the two ends (Seebeck effect). Now if one wire is chromel and the other is alumel (Type K thermocouple) the voltages between the proximal and distal ends will, for the same temperature difference, be different. If the wires are joined at one end clearly there will be a voltage difference between the two unjoined ends and that difference will depend on the wire types, the temperature at the joint and the temperature at the terminal end (the temperature difference from one end to the other). A millivolt meter placed between those two ends will measure that voltage difference. Now if we connect each of those wire ends to, say, a copper wire of some length (actually it doesn't matter how long, within reason) and connect those to the millivolt meter it will read the voltage at the ends of the thermocouple wire even if the meter and the junction point with the thermocouple wire are at different temperatures because the Seebeck voltages in the copper wires cancel each other. Now if the meter and junction point are not at the same temperature the meter is going to interpret the voltage reading as if the ends of the alumel and chromel wires were at the temperature at the meter connection point, not the the temperature where the joint with copper wire is made. So the caveat I mentioned above is that the temperature of the place where the joint with copper is made must be the same as the temperature of the meter (where the temperature is measured and used to convert voltage to thermocouple temperature reading). So if your joint is in room air and your meter is in room air you will be fine using copper (or any other pair that are the same) for the extension. If your thermocouple is in the kiln room and the joint is in the kiln room and the meter is in the air conditioned office, that's not so good.Regarding what wire to use for connections, it really does matter, but it's been a long time since I looked at the details.

To verify what I've said get out the trusty Fluke (or whatever you use), plug in the thermocouple and let the reading stabilize. Now unplug the thermocouple, plug in the normal test leads and use put them on the thermocouple banana plugs. You won't see an appreciable temperature difference (other than from air currents, etc.).

Actually it doesn't (with one caveat) and here's why. A lot of people think it is the junction of the dissimilar metals that is the basis for the voltage the thermocouple develops but it isn't. It is that if one end of a wire is at one temperature and the other at another there will be a difference in electrical potential between the two ends (Seebeck effect). Now if one wire is chromel and the other is alumel (Type K thermocouple) the voltages between the proximal and distal ends will, for the same temperature difference, be different. If the wires are joined at one end clearly there will be a voltage difference between the two unjoined ends and that difference will depend on the wire types, the temperature at the joint and the temperature at the terminal end (the temperature difference from one end to the other). A millivolt meter placed between those two ends will measure that voltage difference. Now if we connect each of those wire ends to, say, a copper wire of some length (actually it doesn't matter how long, within reason) and connect those to the millivolt meter it will read the voltage at the ends of the thermocouple wire even if the meter and the junction point with the thermocouple wire are at different temperatures because the Seebeck voltages in the copper wires cancel each other. Now if the meter and junction point are not at the same temperature the meter is going to interpret the voltage reading as if the ends of the alumel and chromel wires were at the temperature at the meter connection point, not the the temperature where the joint with copper wire is made. So the caveat I mentioned above is that the temperature of the place where the joint with copper is made must be the same as the temperature of the meter (where the temperature is measured and used to convert voltage to thermocouple temperature reading). So if your joint is in room air and your meter is in room air you will be fine using copper (or any other pair that are the same) for the extension. If your thermocouple is in the kiln room and the joint is in the kiln room and the meter is in the air conditioned office, that's not so good.

To verify what I've said get out the trusty Fluke (or whatever you use), plug in the thermocouple and let the reading stabilize. Now unplug the thermocouple, plug in the normal test leads and use put them on the thermocouple banana plugs. You won't see an appreciable temperature difference (other than from air currents, etc.).

Clearly you are far more educated on thermocouples than I. Thanks for elaborating.

When I was practicing Omega Engineering used to provide these very elaborate catalogs in hard cover which took up over a foot of shelf space and had volumes for Temperature, Pressure, pH and Conductvity etc. I can't imagine what it would cost them to do that today but each volume had, in addition to listings of their products, tutorials on the basic principles. Though it was years ago I remembered that the thermocouple section of the Temperature book said extension wires are OK as long as they are of the same material. If you understand Seebeck effect it all fits anyway.

Just wondering if this would work. I would like to disconnected the thermocoupler from the control panel.

http://www.ebay.com/itm/252715204914?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

http://www.ebay.com/itm/252715204914?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

Similar threads

- Replies

- 6

- Views

- 361

- Replies

- 7

- Views

- 1K