JoshuaW

Well-Known Member

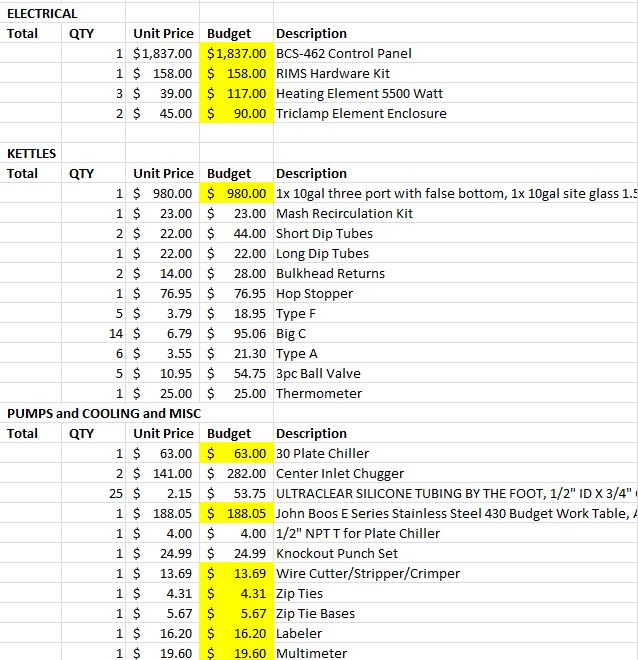

I have been exchanging emails with Ryan from eBrewsupply to work out a custom control panel, and Ben from Spike's Brewing to get some custom welds on kettles. So far this is where Im at:

Panel

This is my version of "Go Big or Go Home". I wanted to be able to power EVERYTHING at once, should it be needed. It probably is a little overboard. The only way we could accomplish this was by using an extra 120v input to cover the RIMS tube. I cant run the RIMS on 240v while the other two elements are going, but that shouldnt be an issue. Im planning on only using the RIMS on 240v when I need on demand hot water anyways. This system will work perfect for back to back batches, as I can run the BK, heat the HLT, and maintain mash temp. Im only going to be running two pumps to start, but this leaves me flexibility for more later on. Im also using the BCS 462 so that I can control fermentation temps in the future.

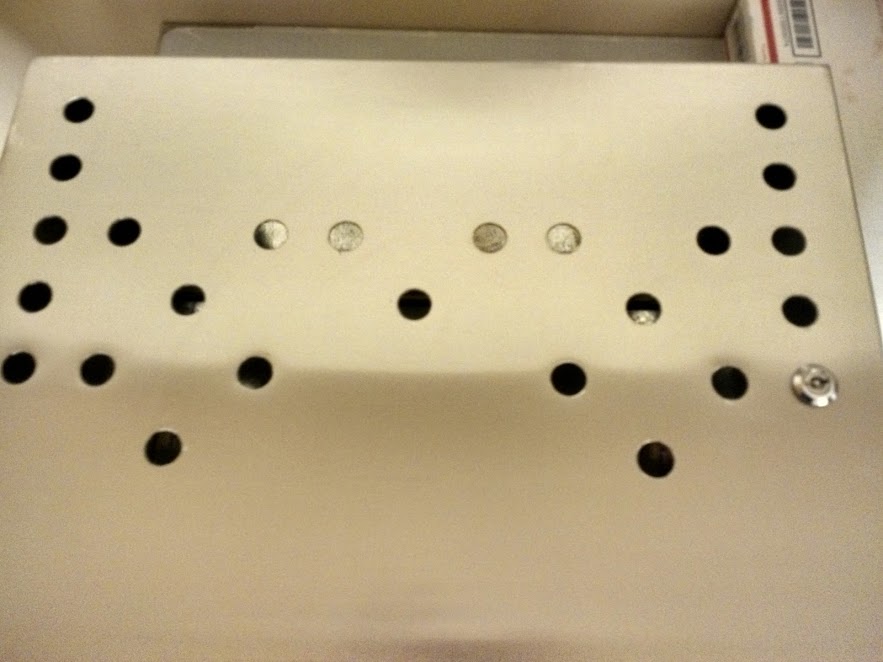

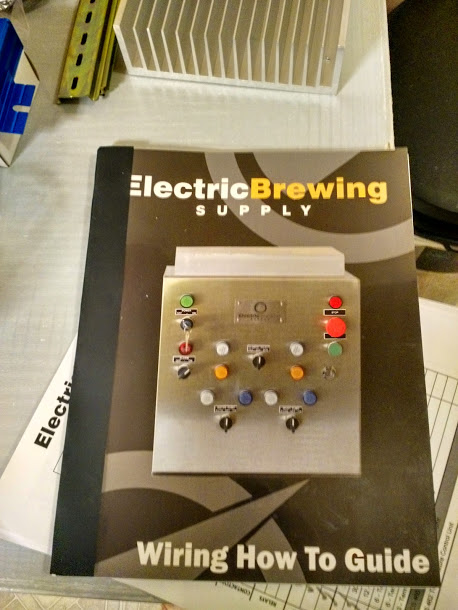

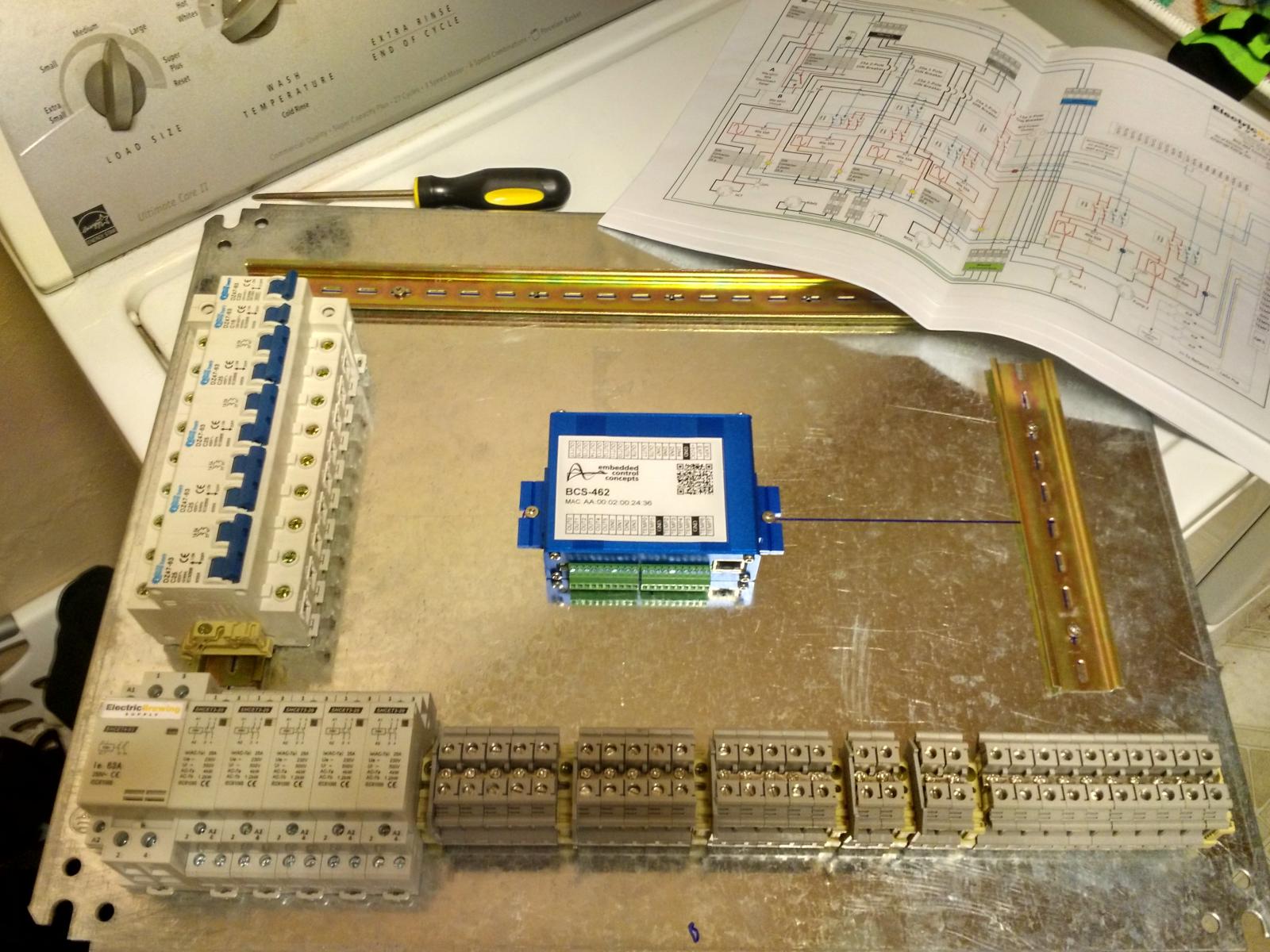

While it was a fairly insignificant amount to have the panel built by Ryan, Im planning on assembling it myself. He is going to send me every last piece and some solid diagrams, and Im going to suffer through this. Im fairly comfortable with certain DIY tasks, but I havent done much electrical, and I think its time I learn! As a safety measure, I will be posting pictures here and probably having an electrician look over it.

Kettles

Im hoping my choice of kettles will allow me to make the occasional 10 gallon batch (smaller beers) for parties and events, something I do maybe a couple times a year. The rest of the time this will be strictly 5-6 gallon batches, which the 10 gallon kettles should have no problem keeping up with.

Elements/Pumps/Etc

Its going to take a couple weeks for me to get started assembling anything, probably wont be placing orders for another week or so. I have the garage all setup, but Im trying to convince the wife to let me build in the laundry room, because the garage is FREEZING in the winter. Im not having much luck, but we will see. She did say I can setup the table in there to work on the panel, that way it isnt all over the kitchen table. Current strategy will be to just start building in there and see if she makes me move it. If she doesnt, then I will go ahead and move the 50amp from the garage...

What do you guys think? Anything I should look at adding or changing?

Panel

- 50 AMP 240v Input

- 15 AMP 120v Input

- BCS 462

- 2 240v Outputs to power HLT/BK

- 1 120v/240v Switchable Output to power RIMS Tube

- 3 120v Outputs to power pumps and accessories

This is my version of "Go Big or Go Home". I wanted to be able to power EVERYTHING at once, should it be needed. It probably is a little overboard. The only way we could accomplish this was by using an extra 120v input to cover the RIMS tube. I cant run the RIMS on 240v while the other two elements are going, but that shouldnt be an issue. Im planning on only using the RIMS on 240v when I need on demand hot water anyways. This system will work perfect for back to back batches, as I can run the BK, heat the HLT, and maintain mash temp. Im only going to be running two pumps to start, but this leaves me flexibility for more later on. Im also using the BCS 462 so that I can control fermentation temps in the future.

While it was a fairly insignificant amount to have the panel built by Ryan, Im planning on assembling it myself. He is going to send me every last piece and some solid diagrams, and Im going to suffer through this. Im fairly comfortable with certain DIY tasks, but I havent done much electrical, and I think its time I learn! As a safety measure, I will be posting pictures here and probably having an electrician look over it.

Kettles

- MLT - Spikes 10 gallon with a 3pc ball valve, and two ports. One port will be used for the BCS temp probe, the other will be a standard dial thermometer.

- HLT - Spikes 10 gallon with a 3pc ball valve, sight glass, and a single port for monitoring temperature through the BCS. A 1.5" triclamp is also being added for use with Brewhardware's 5500w all stainless element kit

- BK - Spikes 15 gallon with a 3pc ball valve, sight glass, and a single port for monitoring temperature through the BCS. A 1.5" triclamp is also being added for use with Brewhardware's 5500w all stainless element kit

Im hoping my choice of kettles will allow me to make the occasional 10 gallon batch (smaller beers) for parties and events, something I do maybe a couple times a year. The rest of the time this will be strictly 5-6 gallon batches, which the 10 gallon kettles should have no problem keeping up with.

Elements/Pumps/Etc

- 1 Brewhardware RIMS Tube

- 3 Brewhardware 5500w Stainless Elements

- 2 Brewhardware Triclamp Element Assemblies

- 2 Center Inlet Chugger Pumps

- 2 Add a Pump Kits

- 3 Dip tubes

- 1 Weldless Recirculation Kit

- 1 Weldless Whirlpool

- 1 60" Stainless Table

- And of course as many camlock QDs as needed!

Its going to take a couple weeks for me to get started assembling anything, probably wont be placing orders for another week or so. I have the garage all setup, but Im trying to convince the wife to let me build in the laundry room, because the garage is FREEZING in the winter. Im not having much luck, but we will see. She did say I can setup the table in there to work on the panel, that way it isnt all over the kitchen table. Current strategy will be to just start building in there and see if she makes me move it. If she doesnt, then I will go ahead and move the 50amp from the garage...

What do you guys think? Anything I should look at adding or changing?